An autonomous water supply device is an individual source and the obligatory installation of a surface centrifugal pump for it for a well, vortex or self-priming. This type of equipment has optimal performance and is capable of lifting water from a depth of up to 16 m.

Purpose, principle of operation and device

Surface discharge equipment is used to lift water from artificial sources, natural reservoirs. Such units are used in everyday life (irrigation, irrigation, filling storage tanks, pools, car washing, organization of autonomous water supply) or in production processes.

All surface water pumps are divided according to the principle of design and operation. There are such types of units:

- Whirlwind. The main element is the impeller (impeller) with blades. It is located either radially or obliquely with respect to its axis. The impeller rotates in the working chamber. It originally gets water from the well. The pressure and suction parts of the chamber are separated by a special jumper. A vortex borehole pump works due to centrifugal force, which first draws in the liquid and then pushes it up. The distance between the impeller blades and the chamber walls is minimal (up to 2 mm). With almost the same dimensions and the number of rotations of the impeller, vortex aggregates create a pressure in the system that is 7 times higher than the performance of a centrifugal apparatus.

- Centrifugal (or self-priming). They also have one or more impellers (in the latter case, the apparatus is called multi-stage). But their blades are not so closely pressed against the walls of the working chamber. The centrifugal unit is capable of lifting water from a depth of up to 8 meters. If the equipment has a remote ejector, its power is amplified up to 16 m. At the same time, the performance of the unit will decrease.

Both types of surface pumps work quite noisily.

Advantages and disadvantages

The main advantages of surface downhole equipment:

- convenience and relative ease of installation;

- compactness;

- optimal pressure for a summer residence or a small private house for 2-3 people;

- the possibility of self-service and minor repairs;

- more favorable price in comparison with submersible models.

The equipment has a number of disadvantages. These include:

- the need to protect the body of the unit from moisture;

- small lower depth of rise;

- high noise level (solved with the help of a comfortable caisson);

- lack of protection against idling, which means the need for constant monitoring of the flow rate of the source.

- the ability to work only with clean water without impurities.

Users prefer a surface pump, as it is convenient to mount / dismantle for the season. In addition, the unit is easy to carry out visual inspection.

How to choose a surface pump

When buying surface-type injection equipment, it is important to consider the following points:

- Suction depth. It is important to remember the ratios of the vertical sections of the pipeline with horizontal. It is 1/4. For example, if the depth of liquid rise is 3 meters, then the pump must be mounted at a distance of 12 m from the source.

- Performance. It is calculated by adding the approximate flow rates for each water intake point per hour. If the pump is needed only for watering, an indicator of 1-2 m3 / hour is enough.

- The pressure.Here you should take the distance from the water mirror to the farthest plumbing point in the house as the optimum indicator.

Every 10 m of the pipeline length reduces the pressure shown in the passport to the pump by 1 m.

It is advisable to choose a device and taking into account the parameters of the well: static and dynamic levels, cross-section of the casing, mark of the bottom base, flow rate of the source.

Installation and connection

To properly install a surface pump, you need to prepare the following elements in advance:

- coarse filter;

- check valve;

- water intake hoses of the desired diameter;

- fitting for connecting the pump to the pipes.

If you need to create a full-fledged pump station, you can additionally buy a storage tank with a volume of 24 liters or more.

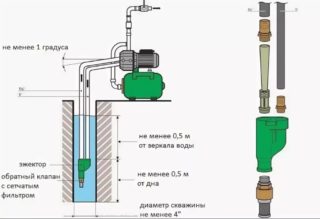

When installing the pump, the following points should be considered:

- The stability of the water supply process depends on the correct location of the unit. This refers to its distance from the source.

- It is advisable to equip a special insulated, but ventilated caisson for the unit. It drowns out sounds and protects the pump from moisture, condensation.

- The parameters of the caisson should be sufficient so that the master can freely carry out maintenance of the equipment.

Installation of the unit is performed in the following sequence:

- A special platform is being prepared for the pump. It is advisable to fill it with the type of foundation.

- Special mounting studs are mounted in the base, which will subsequently fix the unit from excessive vibration.

- Using the fittings, the inlet and outlet hoses are connected. On the first mount a coarse filter. On the outlet - check valve. It will prevent water from draining from the system.

- If the accumulator is installed, it is connected to the outlet hose and then the rest of the pipeline is mounted.

- It remains to lower the intake hose into the well to the desired depth. The hose is fixed to the casing in the head area so that it does not move in the shaft.

- The system is poured with water and equipment is started.

It is strictly forbidden to switch on the surface pump dry.

Operation and maintenance

The surface pump does not require complicated maintenance. However, you need to regularly carry out such maintenance activities:

- Inspect all pipes and hoses regularly for complete tightness. It is especially worth paying attention to the integrity of the check valve. If it is faulty, the pressure in the system will begin to drop.

- It is important to control the level of the water mirror. If the well production rate becomes lower, the pump runs the risk of running dry. This will cause it to burn.

- If the unit is operated only seasonally, it is cleaned for the winter, after draining the water and drying all the elements.

Keep the pump in a dry, insulated place.

The cost of surface pumps for a well

Prices for surface water pumps for a well depend on the type and main technical characteristics of the unit. Approximate prices for equipment in the Moscow region:

- vortex - from 3350 rubles .;

- centrifugal (with built-in ejector) - from 4270 rubles .;

- self-priming (with remote ejector) - from 6815 rubles.

A properly selected unit can serve for more than a dozen years, providing high-quality water supply.