Demand for metal products for pipelines is gradually decreasing, as these are very bulky structures, the installation of which requires the use of heavy equipment, use welding. Instead, you can use plastic pipes, which are easier to install and more durable in use. In addition, plastic does not react chemically with liquids, so drinking water does not lose its qualities and is not contaminated with harmful compounds.

Scope of polypropylene pipes for hot water and cold water

One of the most popular is polypropylene pipes for hot and cold water supply. Polypropylene is the second most common material after polyethylene in the world. They are sometimes mixed in production, since polyethylene has a higher degree of viscosity and is resistant to freezing. So that polypropylene pipes do not crack in the cold or under the influence of cold water, it is necessary to choose the right brand of products - the composition of the material for hot and cold water supply is different.

One of the factors by which buyers choose this type of plastic is the price. Pipes are made on special equipment. Propylene gas is a raw material for production - a toxic substance with a low melting and boiling point. Get it in the process of oil refining or coking coal. It is considered a harmful substance, when exposed to a person, coma and death can occur.

Unlike feedstock, pipe material is absolutely safe for humans and the environment.

The isotactic polypropylene from which pipes for water supply are made is indicated by the IPP mark. They are used in domestic sewage systems and high-rise buildings. The strength of the material depends on how high the temperature of the pumped fluid in the system. It is not recommended to increase the pressure in pipes with hot water, the temperature of which is about 90 degrees, since polypropylene becomes viscous and at a pressure above 6 bar the pipe may burst.

Types of polypropylene pipes

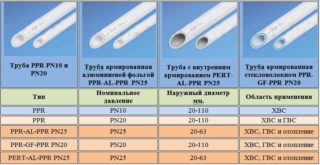

For domestic hot water and cold water use different composition for the production of pipes. Distinguish the finished product by material and method of reinforcement.

- The random copolymer, which is designated PP-R, is suitable for hot water, melts at 170 degrees, breaks at minus 20 degrees. With constant exposure to hot liquids of 95 degrees with short-term drops of up to 110 degrees, the service life is about 5 years.

- PP-R-CT is a novelty of German manufacturers, which has very high strength indicators. Service life at 110 degrees and short-term drops of up to 130 degrees for about 15 years.

- The block copolymer - PP-B - is intended for cold water supply.

- Homopolypropylene - PP-H - is resistant to high pressure, but is used for cold liquids. Most often used in industrial enterprises. Melts at a temperature of 140 degrees, breaks at 0 degrees.

- Crosslinked polypropylene is a rather expensive material with high strength values.

For an external system, you need to choose pipes with a coating that protects them from ultraviolet radiation.

Reinforcement reduces the coefficient of thermal expansion, so products have a higher strength than unreinforced. There are several ways:

- using fiberglass;

- aluminum foil, which is placed closer to the inner diameter of the pipe;

- aluminum foil placed closer to the outer diameter;

- using composite materials.

Products with composites and fiberglass are considered the highest quality.

Specifications

The indicators by which the buyer chooses polypropylene pipes for the home system:

The indicators by which the buyer chooses polypropylene pipes for the home system:

- the length of all products is predominantly the same - 6 m;

- the diameter of polypropylene pipes for water supply can be selected from 15 to 1200 mm, depending on which house the pipes are purchased for;

- marking allows you to determine for which water the products are intended, as well as the maximum pressure in the system;

- the inner diameter helps to calculate the volume of water per unit time;

- wall thickness - for products designed for high pressure, the walls will be thicker.

The technical characteristics of low-quality products are very different from the factory ones, so when trying to save money, difficulties in operation may arise.

GOST requirements

There are quality standards for plastic products:

- Polypropylene pipes are available only with a round cross-section, this configuration contributes to an increase in strength in pressure systems.

- Products can be used both for industrial purposes and in home systems, as well as high-rise buildings.

- Polypropylene is suitable for industrial and drinking water at the same time.

- The pipes withstand the pressure of the liquid, depending on the marking.

Pipes can be single or multi-layer.

Labeling of PP pipes

Marking is the main parameters encrypted in the letter designation. With its help, products that are most suitable for technical characteristics are selected:

Marking is the main parameters encrypted in the letter designation. With its help, products that are most suitable for technical characteristics are selected:

- PN10 - maximum pressure 1 MPa. They are used to equip a warm floor in a room where the temperature of the liquid is not more than 45 degrees, as well as for cold water. Outer diameter from 20 to 110 mm, inner from 1.9 to 10 mm.

- PN16 - maximum pressure up to 1.6 MPa. Withstands temperatures up to 60 degrees. It is used for the construction of a warm floor.

- PN20 - designed for pressures up to 2 MPa, the permissible temperature at this pressure is 80 degrees.

- PN25 - reinforced pipes designed for heating systems with pressure up to 2.5 MPa. Allowable temperature up to 100 degrees. Used in industrial systems.

When selecting products, two parameters must be taken into account - pressure and resistance to heating, since a pipe with a strong temperature difference can be extended by 15 cm. Reinforced products are often purchased for hot water supply.

Standard sizes

The sizes of polypropylene pipes for cold and hot water supply are selected taking into account where they will be used.

In home systems, products with a diameter of 20 to 32 mm are used. If the length of the water supply is less than 10 m, a pipe of 20 mm is suitable. If from 10 to 30 m - 25 mm, over 30 meters - 32 mm.

The diameter also affects the throughput of the system, so when choosing it, the number of residents in the house and the volume of water consumption are taken into account. With a large number of turns and branches, it is desirable to choose a wider diameter. In pressure systems as well.

When arranging a warm floor, a diameter of 16–18 mm is used, for supply communications - a minimum of 20 mm, and when organizing risers - a minimum of 25 mm.

Criterias of choice

The main recommendation when buying polypropylene pipes is the choice of products from one batch of one manufacturer. The composition of the substance may partially change and the quality of the pipes in different deliveries will be uneven. This will affect the butt joints and the durability of the structure. The purchase of pipes from different manufacturers may lead to the fact that the connecting elements will be unsuitable due to the difference in size. Each manufacturer has its own recipe for a substance; a mismatch can lead to failure of the entire water supply system.

It is also worth paying attention to such indicators:

- Estimated fluid temperature in the system.For hot water it is better to choose reinforced products.

- Estimated pressure. When heated, the material becomes less durable and may burst.

- The diameter should correspond to the area on which the pipes are mounted.

You should not save if in the system there are short-term jumps in temperature or pressure, which sometimes happens in centralized systems. In this case, it is better to buy reinforced expensive polypropylene, whose service life is longer.

In home systems, where the pressure usually does not exceed 1 MPa, you can use ordinary pipes, but follow the manufacturer's instructions for which water the product is intended - hot or cold.

Mounting Features

It is not recommended to use the adhesive bonding method, since the walls of the polypropylene are very smooth, which does not allow to achieve the desired bond strength. The ends of the pipes are joined only by heating, during diffusion a strong seam is formed. At the same time, pipes never break in these places.

It is not recommended to use the adhesive bonding method, since the walls of the polypropylene are very smooth, which does not allow to achieve the desired bond strength. The ends of the pipes are joined only by heating, during diffusion a strong seam is formed. At the same time, pipes never break in these places.

To install the polypropylene pipe system, you will need the following tools:

- pipe cutter;

- soldering device.

It should be borne in mind that during measurements minus those sections that will be soldered into corners or couplings. It is approximately 15 mm.

Stages of installation work:

- Measurement of the sections along which the pipes will pass.

- Cutting and marking with a pencil the correct position of the fittings, since after hardening the plastic, the wrong position cannot be corrected.

- Both parts are heated on a special device for soldering pipes, then connected along the intended lines and held for 6 seconds.

From the moment of heating to the joint, no more than 4 seconds should pass, otherwise the material cools down and the quality of the joint will be low, in this place water can subsequently leak. Before heating, the ends of the pipes are degreased with alcohol or gasoline.

Along the route of the highway, plastic clips are installed to fix the pipes. They should not tightly cover the product so that thermal expansion is compensated. Connections are considered non-separable, therefore, if a section of the trunk is damaged, it must be completely replaced.

Advantages and disadvantages

The advantages of polypropylene pipes and structures that can be manufactured using them quite a lot:

- corrosion resistance, due to which the water will be clean;

- resistance to biologically active substances - acids or alkalis;

- low thermal conductivity - no heat loss;

- simple installation - you can create a system of any complexity;

- smooth inner surface, due to which precipitation does not accumulate inside and high hydraulic pressure is not created;

- low cost.

Polypropylene also has disadvantages, but there are few of them:

- you need to carefully select the material so that it is suitable for specific operating conditions;

- special tools are used for installation, so you will have to buy or rent them.

It is possible to purchase low-quality products, so it is recommended to choose proven points of sale.

The prices of polypropylene pipes and fittings for water supply depend primarily on the brand of the manufacturer. Imported analogues are more expensive, but they can be upgraded with new additives and additives that affect strength and increase service life in extreme conditions.