A huge number of submersible pump models are available on the market, since the well is the most affordable way to supply private houses with water. Water reservoirs are not always located close to the surface; therefore, they are not accessible to pumping stations. Despite its high cost, well aggregates are in great demand among the population.

Purpose of submersible pumps

Basically, submersible pumping equipment is used to lift liquids from sources located underground. Most of them - multi-stage - the deeper the well, the more steps that create strong torque and maintain pressure in the system.

Well pumps can operate very deep in artesian wells - they are called deep well pumps. They lift liquid from 300 to 400 meters, industrial models - even deeper.

Submersible equipment is used to equip home-made pumping stations. Since similar purchased units cannot raise the liquid below 8 meters, there is a need to connect the hydraulic accumulator to the submersible submersible pump, as well as to install a pressure switch.

Due to the high pressure, submersible type equipment is used in summer cottages for watering the garden, in drip systems, for arranging a street shower. Management can be manual or automatic. The mechanics are suitable for a one-time use, but for the water supply of a private house, it is better to install automation so that the relay is activated due to pressure drops and independently turns on the unit.

Where are downhole tools used?

Submersible pumps are used in water supply systems of private houses. In this case, install any household model that is suitable for technical specifications.

Liquid also flows to the water tower thanks to submersible equipment, and from there it is distributed further. Here, more powerful units are needed that can service several country or residential houses.

Powerful submersible pumps extract mineral water from the bowels of the earth, followed by liquid spills before being sent to points of sale. Mineral springs are located deep - up to 1500 m, therefore, pumps for pumping are used industrial type, with many stages.

Downhole equipment is suitable for wells. Some models according to the instructions can be installed horizontally, but not all are suitable for this. For shallow wells, units with low power are selected.

Types of equipment, technical specifications

Submersible pumps are domestic and industrial. The difference in power, as industrial models are most often deep-sea and pump liquids from a distance to a water mirror of 1000 meters or more.

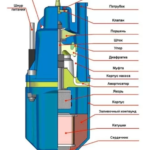

The installation scheme of the rod and rodless units is different. In the first case, this is a device whose engine is located on the surface of the earth, and a rod is lowered into the well - the submersible part, which is necessary for transmitting thrust.

Rodless mechanisms are a pump and an engine in one housing. It is more convenient during installation and operation, therefore, such models are more common in everyday life.

Pumps differ in design:

- centrifugal;

- vortex;

- screw;

- vibrating.

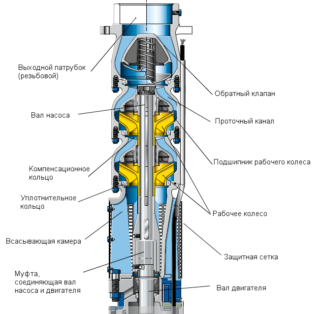

Centrifugal units have a working mechanism in the form of a wheel with an impeller, which rotate on the shaft using electricity. Under the action of centrifugal force, water rises along the walls of the housing into the outlet pipe. In the middle part, an area of reduced pressure is created, which sucks a new portion of the liquid.

Centrifugal mechanisms are the most powerful of all existing. The design can be from one step to 20. On average, for domestic needs, 3 to 4 wheels with blades are enough.

The weak point of the centrifugal pump is the impeller. If sand or stones are present in the water, sooner or later they will disable the mechanism, so for such devices you should immediately buy a filter if it is not provided in the kit. Fine sand fractions penetrate the casing even with a coarse filter, so the inner working part must be made of durable metal. Because of this, centrifugal pumps are more expensive than, for example, vortex pumps.

Vibration units work like piston mechanisms using a membrane that creates high-frequency vibrations. Such equipment is characterized by low power and, therefore, low pressure. Suitable for summer cottages, but similar equipment is not used for water supply of a private house. The cost of vibration pumps is not high. In addition, there is a danger that vibrations will destroy the casing.

Vortex pumps are similar in principle to centrifugal pumps. A distinctive feature is the presence on the walls of the grooves, which enhance the flow and turbulence. The design is simpler, so the price of a submersible pump for vortex type wells will be lower. Vortex equipment is designed for a very clean liquid, so if there are solid inclusions, it quickly fails. The pump operates silently and does not produce vibrations that destroy the well.

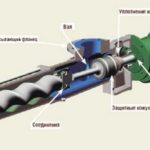

Screw units have a simplified design. Water rises with the help of an Archimedean screw. Such equipment is practically not used for water supply systems, but it has found application among summer residents who make wells to irrigate the site. The pump can even work with dirty water that is pumped from rivers or lakes. At industrial enterprises, screw equipment is used for pumping viscous liquids.

- Vortex

- Vibrating

- Screw

Advantages and disadvantages

Each type of submersible pump has its own advantages and disadvantages. For example, centrifugal pumps are very sensitive to the cleanliness of the pumped liquid. Their disadvantage is the high cost compared to all other species. The rodless centrifugal unit is silent in operation, since its body is in liquid. The service life depends on the number of on and off cycles, so the accumulator is most often connected to it in order to extend the operating time.

Disadvantages of vibration pumps:

- React to sand in the water.

- Lack of automation elements.

- They quickly silt the well, as they create waves that raise dirt from the bottom.

- High noise level.

- Low power and pressure.

- Short service life.

The advantages of screw equipment include:

- high head;

- low noise level;

- ability to pump out dirty liquid without damaging the housing.

The efficiency of the screw mechanism is low, the productivity is low. Frequent replacement of parts is required, since there are many rubbing elements inside the case.

Criterias of choice

Before you buy a unit for a water supply system, you need to take into account the technical characteristics of submersible pumps for water wells, and also decide what the equipment will be used for.

Before you buy a unit for a water supply system, you need to take into account the technical characteristics of submersible pumps for water wells, and also decide what the equipment will be used for.

Factors that play an important role in the operation process:

- The need for the amount of liquid for a private house and residents living in it.

- The pressure.If the well is located far from home, you need power that can bring fluid to the entry point through a horizontal pipe. If the house is two or three-story, it will take effort to raise the liquid to the height of the building. Power is usually selected with a margin - in case of installing additional points of water consumption or building a garage, bath, pool.

- Well depth. For sources in the sand there is no need to install powerful equipment, but for artesian wells a productive centrifugal pump will be required.

- The quality of the fluid handled is clean or dirty. Depending on this, you can choose a mechanism that can fully work and will not break quickly.

- The temperature of the pumped liquid.

- The presence of protection mechanisms - dry running sensor, overheating.

- The materials from which the internal parts and the housing are made. The metal components of the structure provide better tightness and last longer.

- The diameter of the pump relative to the well. It is necessary that at least 2 cm remain from the pipe wall to the casing, so that the fluid flows around the unit and cools it. Correctly selected size ensures that the equipment does not get stuck inside the pipe.

- Removing the electrical outlet from the installation site of the pump. The cable must be of sufficient length.

In order not to overpay, you can first consider domestic-made devices. If they are executed with high quality, their price will not be very cheap. If you count on long-term operation, it is better to select equipment of German, Italian or Swedish brands.

Features of installation and connection

Installation of the pump is carried out according to the instructions. You can entrust the installation to professionals, but if the well is properly organized, it will not be difficult for a beginner to install the unit. In the instructions, all steps are described in detail. For fastening, you need to use durable materials so that the unit does not break off during operation.

After installation, it is necessary to revise the well and pump once a year - to clean, rinse. For this, the mechanism is taken out and inspected. Centrifugal imported pumps do not require frequent repairs or maintenance, but all other types require regular cleaning and flushing of the housing from dirt and sand.

The cost depends on the technical characteristics of the equipment, as well as the brand of the manufacturer. It is not recommended to buy very cheap Chinese pumps, as they break quickly, and it is almost impossible to find spare parts for them. In addition, the model may not be collapsible, so it will have to be thrown away.