Plastic pipes have already conquered the consumer market due to their characteristics and low cost. The assortment continues to grow, because manufacturers are constantly developing new product modifications that are now not much inferior to steel and cast iron pipes. Each type of polymer material has its own characteristics, so first you need to figure out what this or that plastic is suitable for, and then select the dimensions and calculate the number of pipes.

Scope of plastic pipes for water supply

Polymer pipes are used not only to equip the water supply system - external or internal. They are used to transport gases and chemically aggressive substances. Plastic is a neutral substance. It does not react with acids or alkalis. Products are used for laying sewers, since the inner surface of the pipes does not contribute to the propagation of pathogenic bacteria - microorganisms cannot form colonies.

Depending on the technical characteristics, polymeric materials are used in hot and cold water systems. It is only necessary to choose the right pipes so that the operating temperature range matches the capabilities of the plastic.

There are especially strong polymers that are operated at very low temperatures. They are suitable for the construction of an autonomous water supply and sewage system in the extreme north, where the level of soil freezing is about 2.5 m. It is important to take this indicator into account, since a certain amount of water is always in the soil. Turning into ice, such a liquid is able to deform the line if it does not have a margin of safety, so the pipes are laid either to a great depth, or other materials are selected.

Plastic pipes are used for casing of wells of any depth, even artesian, whose depth is about 300 m. For summer residents and owners of greenhouses, polymers are a cheap solution for organizing watering in the summer. It is known that plastic does not withstand direct sunlight and quickly loses its quality, but its cost is not so great as to worry about replacing.

To replace and strengthen old steel water pipes, the method of internal introduction of a plastic pipe after preliminary cleaning of the old one is used. Thus, the liquid begins to flow over the new plastic and the water becomes cleaner.

Advantages and disadvantages

Polymer pipes are the most popular in the following parameters:

- do not react to moisture, unlike steel products, corrosion does not damage the inner walls, and they can remain intact and clean for a long time;

- the material is non-toxic, drinking water does not lose its taste;

- plastic has low thermal conductivity, it maintains the temperature of the transported fluid, which is important for heating systems;

- noise is lower than that of metal pipes;

- you can choose a modification that will tolerate temperature extremes, but such products are more expensive due to various additives;

- plastic pipes are easy to install - connect them with fittings, couplings, welding;

- the weight of the products compares favorably with heavy cast-iron, ceramic and steel structures, therefore, for laying plastic, you do not need to attract special equipment and pay for its rent.

The disadvantages of polymeric materials are manifested in the case when they are incorrectly selected or poorly mounted. Basically this happens when the work is done by lay people.

Types of pipes and their characteristics, requirements in accordance with GOST

According to the material, pipes are distinguished:

According to the material, pipes are distinguished:

- polyethylene - plain or crosslinked;

- polypropylene;

- metal plastic;

- PVC or PVC.

Pipes from low pressure polyethylene most often used in cold water supply systems, for example, for transporting water to a house from a well or well. The working temperature of polyethylene is from 0 to 40 degrees, the pipes withstand a pressure of 25 atmospheres. There is raw material from which "technical" pipes are produced - usually this is secondary production waste. There are separate requirements for drinking water, from which material to produce pipes. If the trunk is planned to be installed on the soil surface, soot is added to the polyethylene - it protects the plastic from ultraviolet rays. Such products are black. HDPE combines the durability of cast iron and the strength of steel, but at a lower price. Theoretically, the material is able to serve about 300 years. The manufacturer claims a guaranteed service life of 50 years.

Polypropylene pipes more resistant to hot water and can withstand up to 85 degrees for a long time. Polypropylene will last about 50 years in a cold water supply system, and up to 25 years in a hot water supply. Given the features of the domestic central heating system, in which short-term emissions of boiling water with a temperature of about 100 degrees can occur, polypropylene is a good solution for an apartment. In a private house, the temperature in the boiler regulates the temperature, so it is unlikely that the material would be damaged. Like all other plastic pipes, polypropylene is not subject to corrosion and is chemically neutral. It conducts heat and sound waves poorly, able to work in pressure systems. The material does not bend well, therefore, to turn the highway, various additional elements are used - tees, bends, corners. Czech polypropylene is considered more expensive, it is white and slightly stronger. Turkish manufacturers save on aluminum and do not observe the same thickness of plastic in all areas, their pipes are cheaper.

Metal plastic - This is a multilayer material. Plastic - cross-linked polyethylene, inside of which aluminum or copper foil is sewn. Two layers of glue provide the strength of the connection of the polymer and foil. Cross-linked polyethylene has high quality characteristics, one of which is the preservation of the geometric shape when heated. Plastic pipes bend well, which saves on connecting elements. When using them, complex expensive tools are not needed, which facilitates the installation of a water supply system for beginners and non-professionals.

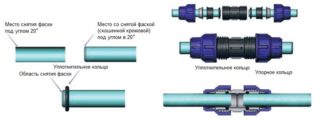

Unplasticized polyvinyl chloride - material that is used in pressure and non-pressure water supply and sewage systems. Chemically aggressive substances and liquid food products can be transported through such pipes. PVC is completely safe. The walls of the pipes are three-layer - this allows you to reduce the weight of the products and its thickness without sacrificing strength. Connect the elements using a bell, where a rubber o-ring is inserted. To make the connection strong, the joints are cleaned of dirt and grease, as these substances damage rubber seals over time.

Criterias of choice

The selection criteria should be based not only on the quality of the material, but also on other indicators, for example, the cost of installation work. When connecting large diameter plastic pipes, one joint can be much more expensive than the entire pipe. For example, when connecting HDPE pipes with a diameter of 1 m, the cost of the joint will cost about 1000 rubles at a price of 1 kg of pipe about 80 rubles.

The second criterion is the operating temperature of the system for which the plastic is selected.For cold water - one material, for hot water or heating system - another. According to sales statistics, polypropylene and metal-plastic are most often chosen for hot water, since they have the best indicators of thermal expansion and elongation.

The third parameter is the size of the pipes, namely the diameter. Depending on the number of water consumption points and the number of residents in a private house, pipes of a larger or smaller diameter are mounted.

You can choose products of domestic or foreign manufacturer. High-quality Russian pipes are not much cheaper than imported ones.

Dimensions and labeling

The sizes of plastic pipes for water supply are very diverse. The thickness of the walls, the inner and outer diameter, the length of the pipe segment may differ. It should be borne in mind that only products with the same wall thickness and the same size can be connected by welding.

Marking is needed in order to distinguish the characteristics of plastic pipes according to the material of manufacture and technical parameters.

For the house and apartment, pipes with a diameter of 50 and 110 mm are most often used. If the house is large and a large amount of water is consumed per day, the diameter of the inlet pipe should be larger.

Mounting Features

Installation of plastic pipes is carried out in several ways. Some are more suitable for closed systems, which will subsequently be hidden in concrete or walls. Others are intended for an open mode of operation.

There are 4 ways to connect plastic products:

- soldering;

- compression fittings;

- press fittings;

- trumpet.

For installation, additional parts may be required - clamps, adapters for changing the diameter, cross pieces, elbows, tees.

Polyvinyl chloride and polypropylene pipes are assembled by soldering. So that the products do not deform under temperature extremes, they perform the “loop” method, due to which there is no voltage at the joints. This is especially true for polypropylene solid lines, the length of which exceeds 3 meters.

When soldering, the main thing is not to overheat the joints, otherwise the connection will be poorly executed and quickly depressurized. Within 4 seconds, the heated joints must be connected and fixed, otherwise the material will cool and there will be no docking at the molecular level.

For the installation of an external water supply or sewage system, it is recommended to plan the wiring plan so that it has fewer bends and turns. In such areas, blockages most often occur or water reduces the flow rate, which is fraught with the formation of an ice plug.

To protect the plastic from low temperatures, they are wrapped with mineral wool with aluminum foil or electric heating is used. These works must be performed at the stage of laying the pipes in the ground.

The cost of plastic pipes

The cost of plastic products is formed from many indicators - the amount of consumable material and its quality, the distance to which pipes are delivered. The variety of material also matters. For example, the price of PVC pipes for a hot type water supply system will be higher than polyethylene pipes with a smaller operating temperature range.

Products of an imported manufacturer, especially well-known brands, are always higher than the similar quality of pipes of a little-known domestic manufacturer. It is recommended to consult with the manager before buying - you may not have to overpay for the brand.

Due to the popularity of plastic pipes in construction, there are many low-quality products on the market made from recycled materials, unsuitable for drinking water mains. Buying materials for construction is necessary at proven points of sale.