For long-term operation without breakdowns, the well requires qualified service. If you cannot hire a specialist, you can take care of the source of water intake on your own.

Why do you need water well maintenance

The efficiency and duration of the hydraulic structure is determined not only by the correct installation, but also by the observance of the operating rules.

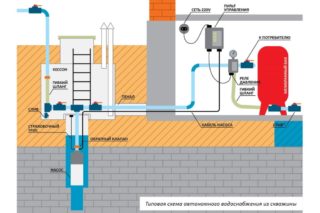

In whatever land the water is drawn in, tiny particles of soil will inevitably fall into it. Mechanical impurities can adversely affect the operation of the pump, and chemical elements that are deposited on the walls of pipes and pressure equipment, lead to the appearance of rust, which causes the depressurization of the compounds.

A negative effect on the operation of the equipment is exerted by voltage drops that can lead to a violation of the insulation of the windings of the pump motor.

To avoid expensive repairs, you need to systematically perform a routine inspection of all elements of the system. It helps to detect minor faults and eliminate them.

List of Maintenance Activities

The list of works to prevent the operation of downhole mines includes checks:

The list of works to prevent the operation of downhole mines includes checks:

- organoleptic quality of water;

- water intake performance;

- pumping equipment;

- accumulator;

- automatic control system.

Periodically, pumping is required to get rid of possible contaminants and preventive flushing.

If the intake facility is operated in winter, seasonal preparation is needed. The casing pipe is insulated to the level of soil freezing, corresponding to the climatic zone. This will prevent freezing of the liquid in the column. You will also need insulation of the caisson, if available.

Pressure equipment test

It is carried out in the following sequence:

- Visual inspection of equipment. By eye, you can determine the integrity of the body and the tightness of all types of connections.

- Shutting down the pump, opening the water intake tap and measuring the pressure in the system. The indicator should stop at zero.

- Checking pressure in hydraulic accumulator. This will require a car pressure gauge. The difference in values when the pump is running and after it is turned off should not exceed 10 percent.

- Starting up the pumping device and monitoring its functioning. After reaching the pressure set on the relay, the pump should shut down.

- Rechecking the pressure in the network, but already without water consumption. If the installation works correctly, the arrow of the pressure switch will be in the red zone corresponding to the maximum.

It is necessary to open the tap and make sure that the arrow on the relay has turned to the green mark, after which the pump is turned on.

Bleeding and maintenance flushing

A well that has just been drilled or clogged must be pumped in order to clear it of crumbled soil or accumulated debris.

For work, you can use:

- well sucker-rod pumping units - SShNU;

- compressors creating a pressure of 12 bar;

- submersible electric centrifugal pumping units - ESP.

The principle of operation of such tools is based on the fact that the air or water supplied under pressure knocks the liquid along with contaminants to the surface.

Performing preventive flushing is necessary only with the seasonal use of the well and with significant time intervals, since when stagnating it is silted. For permanent structures, flushing is not required.

Recommended Frequency

For all maintenance work in an autonomous water supply network, there are deadlines:

- Every day you need to check the physical properties of water - taste, color, sediment and smell. With pronounced changes, a liquid analysis is required in the laboratory.

- Inspection of pipes and the trunk of a hydraulic structure is carried out every two years.

- It is recommended to check the filter and, if necessary, clean it once every three months.

- The frequency of preventive examination of pumping equipment for water wells is prescribed in the accompanying documentation of the device. Despite recommendations, pressure devices, even if they work without malfunctions, should be inspected at least once every 6 months.

The frequency of pumping is determined depending on the flow rate of water. Perform the procedure for an hour.

The results and notes on the conduct of preventive examinations should be recorded in a special journal with the date. These records are used to identify probable malfunctions of both the pressure head device and the hydraulic accumulator, and the well as a whole.