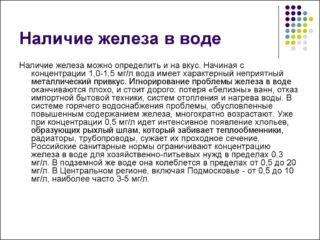

Borehole water in the country or suburban area is one of the cleanest. However, there are frequent cases of increased mineralization or enrichment with manganese and iron. Drinking such a liquid without prior purification is not recommended. If there is a lot of iron in the water from the well, its use can lead to kidney, liver, and even heart attack diseases.

What are the impurities of iron in water?

More often Fe is in a liquid in a divalent state - dissolved, invisible to the human eye. Not knowing about the enrichment of water with this element, you can use a supersaturated liquid for a long time, which leads to negative consequences for health:

- renal failure;

- disorders of the digestive tract;

- problems in the liver;

- pathology of the heart;

- allergic skin reactions;

- harmful effects on the nervous system.

To wash with such water is unpleasant, unsafe.

For household appliances, a large concentration of Fe in water is dangerous for the formation of corrosion, plaque. Laundry from washing in such a liquid acquires a yellow tint.

Water saturated with iron in 2-3 hours after the rise takes on a red color. This means that the process of oxidation of divalent Fe has passed. As a result of the combination of oxygen with a chemical element, it passes into a trivalent form, takes the form of suspensions that are already distinguishable in water.

Signs of Iron

Ferruginous water in the well can be determined by the following signs:

Ferruginous water in the well can be determined by the following signs:

- A change in the color of the liquid some time after it is selected from the well.

- The sediment layer is red in color at the bottom of a glass container with water.

- The liquid smells of iron, has a smell of rust.

- A specific taste of metal in fresh well water and cooked dishes.

- White linen after washing becomes red.

- Boiling forms a fine-grained, rusty residue in the pot.

It is necessary to remove chemical impurities from the borehole resource of a private house in a timely and correct manner, until the problem is felt.

The norm of the content of Fe in water is only 0.3 mg / l. Its large concentration is already negatively affecting the human body.

Methods of water deferrization

It is possible to deal with the problem of over-saturation of the borehole resource with iron both by simple folk remedies and by using more professional installations.

It is possible to deal with the problem of over-saturation of the borehole resource with iron both by simple folk remedies and by using more professional installations.

Upholding

In this method, ferrous iron is oxidized. The method is good for preparing just drinking water. You just need to fill the liquid in a glass container and wait until the sediment in the form of rust settles to the bottom. The upper 2/3 of the water is potable. The inefficiency of this method is that during overflow some sediment can fall into a clean container.

Aeration

Iron removal from a well is performed in two ways:

Iron removal from a well is performed in two ways:

- Pressure. The process involves pumping air into a flask filled with water. After the oxidation process takes place, the liquid feeds into the filtering units (coal, mechanical, ion-exchange). The output is a clean resource suitable for consumption.

- Non-pressure. So-called choking takes place. The liquid is fed into a large tank through a watering can-sprayer (nozzle). Upon contact with oxygen, iron in water oxidizes and precipitates. It remains to remove it through the filters.

The aeration method is considered the most relevant of the household after the installation of de-ironing filters.

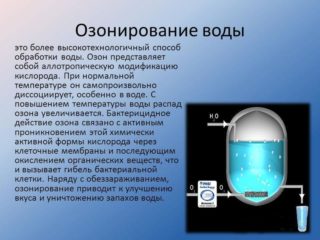

Ozonation

The process is technically more complex:

The process is technically more complex:

- In a special installation, atmospheric air is cleaned of all impurities and contaminants.

- It is fed to an oxygen concentrator, where the substance is converted into a gas mixture. The oxygen content in it reaches 90-95%.

- Processed air enters the ozone generator, where the formation of the desired substance occurs.

- Water is enriched with ozone according to the type of aeration.

Ozonation is used for industrial, large-scale purposes. Domestic installations are inefficient because they are not able to produce the right amount of ozone for high-quality water purification. This is due to the security of the ordinary consumer. Ozone is an explosive gas.

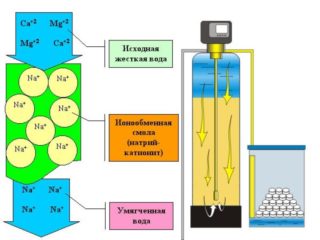

Ion exchange systems

A certain resin is loaded into the equipment, which provokes the exchange of iron ions to sodium ions. Parallel downloads cope with manganese and soften the water. However, ion-exchange systems are not always suitable. The resin copes only with that water, the iron content of which does not exceed 3 mg / l. If the concentration of Fe is higher, the load will not cope with the task and will quickly fail.

A certain resin is loaded into the equipment, which provokes the exchange of iron ions to sodium ions. Parallel downloads cope with manganese and soften the water. However, ion-exchange systems are not always suitable. The resin copes only with that water, the iron content of which does not exceed 3 mg / l. If the concentration of Fe is higher, the load will not cope with the task and will quickly fail.

Do not dispose of ion exchange resin in household waste. This leads to environmental pollution.

Reverse osmosis

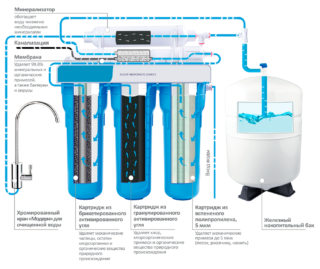

This method of purifying water from iron from the well to drinking in a country house is the most effective. Reverse osmosis plants are several degrees of liquid treatment and its additional saturation with minerals, if necessary.

The principle of water purification from iron is simple - a liquid under high pressure passes through a fine-grained membrane, which passes only water molecules, but not ions of chemical elements, lime, nitrates. All waste is dumped into the sewer in one gulp. Thus, the membrane does not clog, but still requires regular cleaning.

Reverse osmosis systems cope with a well fluid whose iron concentration does not exceed 15 mg / l.

It is recommended that you buy a reverse osmosis installation from a trusted supplier and order its turnkey installation with subsequent maintenance.

Filtration

Filters can remove iron from water from a well if it is in suspension - trivalent. It is recommended to use high-power line filters as treatment plants. This is the equipment with which multilevel filtering is carried out. Each cartridge of the main filter has its own load - coal, mesh, membrane. The advantages of this method of iron removal:

- reasonable cost of installations;

- good performance;

- easy installation and maintenance, which even novice masters can handle.

It is advisable to select washing filters that can be used an unlimited number of times by the method of flow processing of the mesh or with the replacement of loads. However, you can buy an inexpensive budget option with a replaceable cartridge - Aquaphor jug. Its price is from about 350 rubles to 2000. A removable cartridge allows you to seriously reduce the concentration of iron for 1-2 months (depending on the number of people living in the house).

Catalytic method

A catalytic iron de-ironer from a well is a special installation in which Fe2 is oxidized to a trivalent state. Often for this purpose, special fillings are used, which are based on manganese dioxide. In such an environment, iron molecules are oxidized and settle on the surface of the granules. Then the catalytic loading is flushed, all waste is discharged into the sewer.

For this method of cleaning, a number of disadvantages are characteristic:

- High consumption of water for washing the load, with which you need to regularly clean the backfill layer.

- Low efficiency with respect to organic iron, since it forms a thick film on the surface of the catalytic medium. As a result, the cleaning process is reduced to zero.

- Lack of effectiveness with a high Fe content in water of more than 15 mg / l.

The situation is further aggravated by the presence of manganese impurities in the liquid, which are more difficult to dispose of in parallel with iron.

Electrochemical purification method

Water is passed through a special field in which the anode and cathode are the main ones. As a result, fluid electrolysis occurs. As a result, the medium volume is divided into alkaline and acidic. Iron precipitates.

A similar method of removing Fe is used in enterprises and industrial wastewater treatment plants when processing large volumes of water.

Reagent Use

These substances provoke the process of oxidation of iron dissolved in water and its reduction to a suspended state. As reagents are widely used:

- hydrogen peroxide;

- sodium hypochlorite.

A similar method is often used at industrial wastewater treatment plants, because in addition you need a lot of large sedimentation tanks for the treated liquid and clarification filters. And it’s not cheap.

The main danger of using reagents in everyday life is an incorrect dosage calculation, which can lead to dangerous consequences.

Only high-quality prepared water is suitable for drinking and benefits the body. It is imperative to make a good de-ironing film on the out-of-town area, even if seasonal residence in the house is assumed.