Each equipment has its own resource of work. In the absence of factory defects and the correct connection, the pumping station will work for a long time. If during installation errors were made or mechanical deformation of the pipeline occurred, the pumping equipment will begin to work intermittently. Any deviation must be diagnosed immediately to prevent a final breakdown. Some parts are expensive - it’s easier to buy a new device than to repair an old one.

The principle of operation of the pumping station

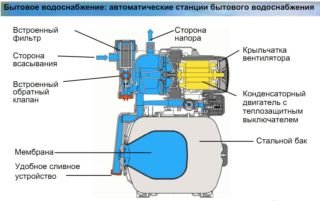

The pump station consists of three main components - the pump itself, the battery, and the control unit. In home systems, surface pumps are most often installed that draw water through a hose or pipe. Housing and automation elements are out of fluid. A battery is a container with a rubber sealed bulb inside. When fluid is collected, the rubber is stretched, extreme pressure is created and the motor shuts down. The tank delivers water through pipes to the intake devices in the house. The automation unit with an attached pressure gauge regulates the pressure. If the pressure drops, then at its lower point the engine turns on again and the pump starts pumping water. This mode of operation protects the device from overheating and premature failure.

The pump station consists of three main components - the pump itself, the battery, and the control unit. In home systems, surface pumps are most often installed that draw water through a hose or pipe. Housing and automation elements are out of fluid. A battery is a container with a rubber sealed bulb inside. When fluid is collected, the rubber is stretched, extreme pressure is created and the motor shuts down. The tank delivers water through pipes to the intake devices in the house. The automation unit with an attached pressure gauge regulates the pressure. If the pressure drops, then at its lower point the engine turns on again and the pump starts pumping water. This mode of operation protects the device from overheating and premature failure.

Changes in operation in one of the nodes entail malfunctions in other parts of the equipment.

The pump pumps water without interruption

There are several reasons why the pumping station does not shut off after water has been drawn. One of them is the clogging of the inlet in the pressure switch housing. Before you start looking for a more serious reason, you need to check whether the debris has got into the automation unit and whether the contacts are interfering. Contact oxidation is also possible. The block is disassembled, the contacts are cleaned and everything is assembled in the reverse order.

The second reason is fluid leakage. In this case, the pressure cannot rise to its maximum value, which prevents the contacts from tripping to shut down the equipment. Most often, leaks occur in the battery pack. If you lubricate it with soapy water or shaving foam, you can determine the place of leakage. To seal, it is necessary to degrease the area and solder. A leak may occur due to a violation of one of the joints of the trunk. Water will constantly flow out of the crack - in order to maintain the required pressure, the pumping station will have to work continuously. You need to look for a problem place right away, since the engine can burn out due to constant overloads and lack of cooling.

A drop in the water level in the source leads to the fact that no liquid flows through the suction pipe, because of which the pump station does not gain pressure and the device does not turn off. For troubleshooting, lower the suction hose deeper. If the groundwater is completely gone, you will have to look for a new location for the well.

One of the common causes of untimely engine shutdown is a rupture of the rubber membrane inside the accumulator housing. This may be a factory defect or incorrect relay settings. With a very high upper pressure threshold, the rubber does not withstand and bursts. The problem can only be fixed by installing a new membrane and adjusting the relay.

Damaged rubber membrane can be vulcanized. For this, it is removed, repaired and put back.

If there is a filter at the entrance and it is clogged with clay / sand particles, the station may not turn off for a long time until it draws water and the pressure rises to the desired level. In this case, the filter must be cleaned or replaced.

No water enters the pipes when turned on

The reason may be impeller wear. In this case, the station will operate continuously, and water will not flow. Sometimes the internal parts in cheap pumps are made of plastic. They quickly wear off when exposed to sand or stones. The impeller is preferably metallic.

The engine is disassembled and inspected. If signs of abrasion are visible at the edges, impeller replacement is required.

Water flows jerkily

The reasons for the operation of the pumping station jerky:

- drying out of the well;

- surges in pressure or tension;

- membrane damage;

- errors in the arrangement of the well.

If air enters the pump along with water, this will lead to an uneven flow of fluid to all distribution points located in the house.

Clogging of the pumping station leads to a shutdown. The pressure drops and particles of debris stick to the inlet. The device turns on again and draws in dirt, which again causes the engine to stop. At the same time, water will go in jerks in the house.

If the equipment does not work evenly from the very beginning, then the entire trunk is not mounted correctly - there are leaks. Do not fill the pipes with earth until the pump has been tested, otherwise you will then have to dig it again and inspect the entire area.

Check also the compliance of the pipe diameter with the suction height. At the same time, it is necessary to check the well if its productivity has not decreased - it may be necessary to clean it of sludge.

In the area from the suction to the inlet, air leaks can be observed. In this case, the pumping station works, but supplies water in jerks. The situation is corrected by deepening the pipe into the well. If it does not help, then the tightness of the suction pipe is broken - it is taken out, checked and repaired.

The pump does not turn on

First you need to check if there is voltage in the network. The device must be turned off if the stabilizer is not connected so that the engine does not burn out.

Sometimes contacts burn out. To resume the work of the station they need to be cleaned with sandpaper. The device at this moment must be de-energized.

The biggest nuisance is a burned out engine. If you hear the smell of burning insulation, the motor will have to be changed. Changing the winding in a service center is very expensive, so the masters recommend buying a new motor. If possible, get a new pump. In the event of a crack in the bearing or failure of the capacitor, the pump station will also not work - it is necessary to replace damaged parts.

During prolonged periods, a simple impeller sometimes sticks to the casing and cannot move independently. To do this, the device is disconnected from the network and the impeller is manually rotated.

Station often turns on and off

If the pipeline is damaged in the ground, the pumping equipment can turn on and off more often than it should. When turned on, the necessary pressure is created in the system and the fluid enters the storage tank. Moreover, part of it goes into the ground due to cracks or kinks in the pipe. If all nodes of the station are working properly, the problem must be sought in the pipes. To do this, dig the entire trunk and look for a leak. This can take a lot of time, therefore, before starting excavations at the site, all other reasons must be excluded.

With an insufficient level of power supply, the equipment is forced to constantly turn on so that the impeller can gain the necessary speed for pumping water into the system.The reason may be either a power source or the mechanical or electrical part of the device. The inlet and outlet nozzles become clogged after prolonged use, so they are washed with a cleaning solution. Unstable voltage in the home network gives uneven operation of the pump. Check the voltage indicator when the station is running. If necessary, install a stabilizer.

Accumulative capacity during long-term operation may have microcracks through which the fluid escapes. Repair is not advisable - it is better to replace it completely.

The pressure accumulator creates a pressure of about 1.5 atmospheres. When filling the rubber membrane with liquid, the pressure increases and squeezes water into the pipes. If air escapes due to cracks, the desired pressure does not arise. Cracks in the steel structure can be welded or the container replaced.

Ejector damage

Pumping equipment with an ejector allows you to get water from great depths - up to 45 meters, but there are also problems with it. Most often, stones get inside, and there is no fluid circulation in the pipe. In this case, it is necessary to remove the pipes and clean them from accumulated debris, and then rinse with a strong stream of water. This happens when it’s time to clean the well, therefore it is recommended to call the drilling crew, which has the right equipment.

If the ejector breaks or becomes clogged, it is impossible to raise the liquid from a great depth, so the equipment will turn on, but the water will not reach the surface.

The equipment works, but there is no water

First check the check valve. Dirt, sand, clay gets into it, so it can jam and water will not get into the suction pipe. Sometimes after a long period of operation, the valve needs to be replaced.

First check the check valve. Dirt, sand, clay gets into it, so it can jam and water will not get into the suction pipe. Sometimes after a long period of operation, the valve needs to be replaced.

If there is no fluid between the pump and the well, the device cannot start. There is a filler hole in the housing - it must be filled with water.

Sometimes equipment does not want to work from the very beginning. It is possible that errors were made in the calculation of power and the pump does not correspond to the depth of the well. In this case, change the device - its parameters are not enough. Electrical characteristics also affect the operation of the device. If it is designed for a three-phase network, you will have to change the wiring.

Normal blockage can also block fluid flow. Before this, the quality of water usually changes - there are impurities in it. The pressure decreases gradually until it completely stops. First you need to disconnect the outlet pipe and turn on the device - if the fluid flows, then a blockage has formed on another part of the system, possibly at the entrance to the home network, where the diameter of the pipe changes from large to small.

If water does not flow from the pump station, then a plug has formed in the valve or suction pipe.

The equipment can pump fluid from the well, but water leaves the way. First, check the connection points of the pump and the pipeline, as well as the place of entry of the line into the home system.

To make it easier for the craftsmen to understand, you need to know what material the underground pipeline is laid out and how old he is:

- old metal pipes are subject to corrosion due to which holes form;

- plastic insulated structures may freeze and burst.

If part of the plastic line runs outdoors, it can also cause structural damage. Almost all types of plastic without a protective coating are afraid of ultraviolet radiation.

Changing the pipe section is a matter of a few days, so it’s worth considering where to get the water until the workers find the problem and fix it.

Malfunctions in the pressure switch

Most problems during the operation of the pumping station are associated with incorrect relay settings or its breakdown. The essence of the pressure switch is that it is able to close and open the network when the limits set at the factory settings are reached.

Reaching the lower limit, the circuit closes and the device turns on, when the upper limit is reached, the circuit opens and the pump stops pumping water. The relay is accompanied by a characteristic click.

The moment of switching on and off can be set manually. To do this, tighten or loosen two springs:

- The first is large, it is responsible for the moment of shutdown. Twisting it clockwise, you can increase or decrease the pressure indicator at which the device turns off. For example, if previously the device turned off at 3 bars, after wrapping it will turn off at 3.5.

- The second spring is smaller. It is responsible for turning on and shows the difference between the upper and lower values. Factory settings show a value of 1.4 - 1.5 bar.

If the difference in values is small, the station will turn on frequently. This can lead to a quick engine failure due to overheating. In the opposite case, with a large difference, the water pressure in the tap can be reduced to a minimum, which is inconvenient when using a shower, and also affects the operation of the washing machine.

After setting up the relay, it is necessary to pump air into the accumulator using a simple bicycle or car pump with a pressure gauge. For this, the start-up rate of the station, for example 1.8 bar, is multiplied by 0.9, a value of 1.62 bar is obtained. Inflate air and check with a pressure gauge.

Factory defect or incorrect settings during installation

In the event of factory defects or improper installation, the device may not turn on at all. If the installation is done on your own, it is better to call a specialist to avoid damage. With initial malfunctions in the operation of the nodes, the device will work for some time and fail. The warranty card must not be discarded before the end of its life.

If problems began immediately, it is better to replace the station with a more expensive and reliable one. To do this, check the device in the service center and fix the breakdown.