An autonomous water system with water intake from a well or a well is an integral modern part of the life of people outside the city. Such a water supply consists of a pump, a hydraulic accumulator, filters and consumers for various purposes. All of them are interconnected by pipes. There is a small box in this system called a pressure switch. Its purpose is to regulate the pressure of water in the water supply.

How the relay works

The pump runs all the time while voltage is being applied to it. The accumulator accumulates water in itself and distributes it under a certain pressure among consumers. Individually, these devices are just tools that work on their own. For them to work in the system, they must be constantly monitored. For example, turn the pump on or off if the water pressure drops or rises in the system, respectively.

The relay makes it possible to avoid this hassle, because everything will work automatically. In this case, the relay acts on other parameters of the water supply:

- reduces the load on the equipment, consisting of a complex water supply system;

- reduces its wear;

- increases operational resource;

- keeps the water pressure inside the network at the same level.

The principle of operation of the relay is directly related to the operation of the accumulator. Inside the latter there is a membrane that captures and regulates the pressure inside the water supply network. With a small amount of water inside the membrane, the pressure drops. The amount of water increases, the pressure rises.

Turning the pump on and off, takes over the relay. As soon as the pressure inside the accumulator drops, the contacts are closed, through which the current moves to the electric motor of the pump unit. With increasing pressure, the contacts open, and the pump stops.

The design of all relays from different manufacturers is the same. They work on the same principle. The part is inexpensive, and purely constructive it is simple.

Design features of the relay

The main element of the product is a steel plate that responds to pressure changes inside the tank. It bends with increasing pressure, breaking the contacts, and comes to its original position when the pressure drops. There is a short circuit of electrical contacts.

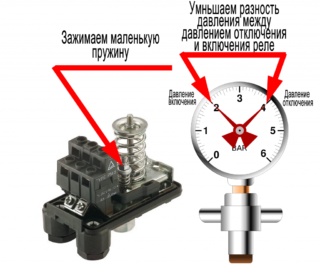

Present in the design of the relay is the so-called spring unit. It consists of two springs of different sizes. The big one is responsible for setting the low pressure - for turning the pump on and off. Small for the pressure difference - the period during which the pump will work. The first is responsible for containing water pressure. You can adjust it with the nut located on top. The second spring is adjusted exactly the same.

The adjustment of the water pressure regulator for a borehole pump must be approached from the position of its correct installation. Therefore, experts recommend installing it next to the accumulator. At its output, pressure differences and turbulence of the water flow are leveled, this is especially noticeable when the pump unit is turned on.

How to set up correctly

The adjustment of the device depends on the technical characteristics of the water supply system. Therefore, it is important to identify them correctly. Required parameters:

The adjustment of the device depends on the technical characteristics of the water supply system. Therefore, it is important to identify them correctly. Required parameters:

- working pressure inside the tank;

- the maximum and minimum pressure that a pump installed in an autonomous water supply network can create.

At the factory, the relay is subject to standard settings. The springs are clamped to a certain height.But, as practice shows, the set values often do not correspond to the technical parameters of the water supply.

It is necessary to begin the adjustment with a large spring. The best option for water pressure inside the network is 1.5 atm., This will be the starting point in the regulation. Usually, reconciliation is carried out by a pressure gauge, which is installed next to the accumulator. It is done like this:

- water is pumped into the hydraulic tank up to 1.5 atm .;

- the pump shuts off;

- tighten a large spring with a nut until the pump starts automatically;

- this is the lower limit that the pump unit will include.

Next, you need to adjust the small spring. It is pressed until the pump shuts off. Typically, a gauge in the range of 2-2.5 atm should be indicated on the manometer. But here everything will depend on the needs of the water supply, the volume of the accumulator.

An important point on which the correct operation of the entire water supply network depends: the pressure in it should always be higher than the same characteristic inside the tank by 0.2 atm. Otherwise, the service life of the rubber membrane will decrease.

Thus, as soon as the pressure inside the accumulator reaches the lower limit, the relay closes the contacts. The pump will turn on and begin to drive water into the pear-shaped membrane. It will expand until the air pressure inside the tank reaches a critical value (up to 2-2.5 atm.). The device will turn off and stop pumping water.

When one of the consumers opens, water from the membrane will begin to flow into the plumbing system. The air pressure inside the tank will begin to decrease sharply. Having reached a critical value (1.5 atm.), The reduced parameter will give an impetus to the alignment of the plate, and it will close the contacts, the pump will turn on.

Criterias of choice

Like all devices working for opening and closing contacts, the relay has one characteristic that you need to pay attention to when buying a product. This is switching wear resistance. Its unit of measure is the number of on and off. The larger this parameter, the longer the device will last. There is a fairly wide range, depending on the brand and manufacturer. There are parts that have switching wear resistance in the limit of 100,000, for others it reaches 5,000,000.

Also, when buying, the time during which the settings are not changed is taken into account. Unfortunately, this parameter is not indicated in the product passport. It can be recognized during operation or consult with specialists who have long been involved in the installation, repair and maintenance of autonomous water supply systems.

The pressure switch installed in an autonomous water supply system solves an important problem: automatic switching on and off of the pumping station when the pressure inside the network drops or normalizes. The device is an inexpensive product, small in size, so its installation is economically viable.