In order for the pump station to turn on and off as the need for water arises, a special device is built into its circuit - a pressure switch. Upon purchase, the factory settings are already set - upper and lower limits at which the device is triggered, but in some cases the pressure switch of the pump station must be adjusted and the readings corrected. Most often this happens with breakdowns in other nodes, clogging after prolonged use or replacing devices.

Definition and purpose of the pressure switch of the pumping station

A relay or pressure sensor performs two functions in the operation of pumping equipment - when the pressure drops to the lower threshold, the electric circuit is activated and the device gives a signal to turn on. When the upper threshold is reached, the circuit opens and turns off the pumping station. At factory settings, the lower threshold is set to a value between 1.5 and 1.8 bar. Top 3 - 3.5 bar. These indicators are not recommended to be changed independently without good reason.

The sensitive organ of the relay is a flexible rubber membrane. When the pressure changes, this part bends to one side or the other, which leads to the opening and closing of the contacts.

The use of a membrane relay made the work of the pumping equipment automated, not requiring constant human intervention. In addition, the service life of pumps and compressors has increased, since they ceased to work continuously. Overheating is the main enemy of appliances, especially those that are not artificially cooled. If submersible pumps are constantly in the water column and do not overheat due to this, then surface pumping stations fail more quickly and some parts have to be changed more often.

Installing a relay is a safe operation of pipes, especially those made of relatively soft material - plastic, polypropylene. A pressure sensor keeps it within acceptable limits. With an uncontrolled increase, pipe rupture is possible. Moreover, hot fluid, if it is necessary to pump it through pipes or heating systems, softens the plastic, and it becomes vulnerable to damage. Given that at the moment most of the water pipes are made of polymer materials, such accidents could occur daily.

Energy saving when installing a pump station with a pressure switch occurs automatically. If in the house no one turns on the taps, the washing machine, the toilet bowl does not work, then the pumping equipment does not turn on. The signal comes when the pressure in the system drops and the device starts to work.

The specialists who created the pumping stations claim that the service life of the device does not depend on the duration of the work, but on the number of on / off cycles. If there is a large storage tank, the station may turn on only once a day. But devices with drives are not the most convenient way to store water, so it was decided to equip the pump with a hydraulic accumulator, which has more advantages. The relay can be configured so that the station turns on less frequently or more often.

The principle of operation and device

The pressure switch was invented at the beginning of the last century. Until today, its design scheme has changed little, the principle of work has not changed.

The sensor consists of the following elements:

- contact block;

- spring regulating the pressure difference (lower threshold);

- large springs of working pressure (upper threshold);

- place to connect electrical wires;

- input for connecting a manometer and a safety valve;

- a hole for the membrane;

- on / off button;

- plastic or metal case.

For some breakdowns, it is necessary to replace the pressure switch, since it is impractical or expensive to repair it. To do this, you need to know how to choose the right device, because manufacturers do not always supply parts for the right model. The policy is to ensure that people buy a new pump, and not repair the old one.

To choose a device, you need to know its type, functionality and working pressure - it is advisable not to lose the instructions for the pump station. There are relays for water intake, air and chemical pumping control. A pumping domestic station usually works with clean water, less commonly with sewage or dirty liquid.

The presence of motor overheating protection may be included in the relay circuit, but this type will cost more. If possible, it is better to buy a device with protection, since the pump station itself is much more expensive.

There is a single-phase or three-phase relay. They are used in pumping stations to protect against dry running. This is a kind of sensor that responds to the power factor generated by the equipment. At low rates, the device shuts off the pump. This is an additional feature, the presence of which makes the device more expensive.

To connect a new relay to the pump, you need to know the size of the flange. It can be indicated by the following numbers: ¼, ½, 3/8.

Some devices have a mechanical start button. It is designed to force the pressure sensor to turn on or off. Other additional features include an unloading valve and a dial.

The operating range of the pressure switch must match the required by the parameters of the pumping station. In the instructions, it is usually indicated by strokes.

When you need to adjust the pressure switch

If the pumping station is purchased ready-made, the factory settings operate in it. When assembling equipment manually from the constituent elements, adjusting the relay is a mandatory step before testing the device. In the operation of individual nodes, there is a relationship with the relay settings, which can interfere with the operation of the device.

With a long line, additional steps may be required to tighten the large springs to increase the pressure in the system. Some residents who have installed autonomous heating and running water complain of a periodic drop in pressure at the moment when the person was in the shower. Water is heated by a boiler or boiler, at the moment of pressure drop it becomes very hot. It is also related to the operation of the pumping station.

When adjusting the upper and lower thresholds of the pressure switch, you need to look for a middle ground. In theory, these two indicators should have a minimum range of values, but then the pump will turn on and off very often, which will lead to its rapid wear. If you set the lower indicator to the minimum value, and the upper one to the maximum, a sharp drop in pressure in the system will be felt. But in this case, the pump will work longer.

Sometimes the working chamber behind the relay membrane is clogged with various deposits from the pumped water. To clean the hole, the rubber is removed, turned over on the other side and collect all the parts in the reverse order. After that, you need to test the operation of the pumping station, check the settings and, if necessary, make a correction.

What pressure should be in the pumping station

It is believed that the pressure gauge should be checked and adjusted every three months. The figures depend not only on the settings, but also on the air pressure in the tank.If the values change over time, it is not necessary to touch the relay settings; you may need to pump air into the tank using a bicycle pump. For example, the initial settings of the upper threshold were 3 atmospheres, after the volume of air in the tank decreased, the pressure gauge began to show 4 atmospheres. In this case, air is pumped into the tank.

You cannot make relay settings when the tank is full of water. In this case, it is impossible to determine exactly how much air is in the system, and how much water, because when the tank is full, the total pressure is the sum of the indicators of water and air pressure.

You can not set the upper limit of more than 80% of the maximum value. In this case, it is better to replace the relay or lower the upper threshold. For example, the maximum threshold is 4 bars. Given the power surges and the gradual deterioration of equipment, including relays, you can not set the upper limit above 3.5 bar, otherwise all equipment may fail.

The smallest difference between the indicators can be 0.6 bar. If necessary, you can set the pump station to the maximum difference so that the device turns on less frequently.

Setting and adjusting the pressure switch

Settings do not always help to solve the problem with the operation of the pumping station. Before touching the springs, it is necessary to find out whether the “sticking” of the contacts has occurred due to adverse operating conditions - increased humidity, condensation, overheating. First, check the contacts, if necessary, sand them with sandpaper and reconnect. All work is carried out with a de-energized device. At the same time, the tank is checked for integrity and the presence of the required amount of air inside, clean the filters. If you have no experience with such equipment, it is better to invite a wizard.

Settings do not always help to solve the problem with the operation of the pumping station. Before touching the springs, it is necessary to find out whether the “sticking” of the contacts has occurred due to adverse operating conditions - increased humidity, condensation, overheating. First, check the contacts, if necessary, sand them with sandpaper and reconnect. All work is carried out with a de-energized device. At the same time, the tank is checked for integrity and the presence of the required amount of air inside, clean the filters. If you have no experience with such equipment, it is better to invite a wizard.

If the matter is really in the lost settings, before starting work it is necessary to prepare a wrench with which the spring will turn. It is necessary to turn on the unit and record the indicators of the upper and lower threshold in order to more accurately determine which indicator needs to be changed and which should be left unchanged.

Actions are performed in the following sequence:

- The station is de-energized.

- The water from the reservoir tank is lowered and the pressure switch cover is opened.

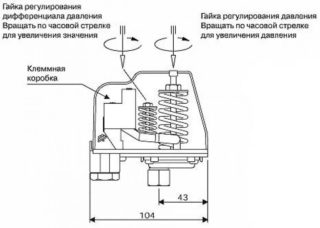

- The switch-on rate is regulated by a large spring. It is usually exposed to 2–2.2 atmospheres. Tighten the nut clockwise until the value is set to the desired number.

- The difference is regulated by a small spring. If it is necessary to decrease the value, the nut is turned counterclockwise; if it is increased, it is turned clockwise.

The difference between the indicators should optimally be 1 bar, so that the pressure change in the house is not felt.

A small spring is used to adjust the difference of indicators. It does not adjust the lower trip threshold.

Features of adjustment "from scratch" and error settings

Setting up a pump station pressure switch with your own hands from scratch is much more difficult. This procedure is required when the equipment is assembled in parts, and not bought in a store. In this situation, you need to consider several parameters:

- air pressure in the accumulator;

- relay capabilities - its operating range;

- line length and pump operation parameters.

The lack of air in the tank will cause the membrane to immediately fill with water and gradually stretch until it bursts. The maximum pressure during shutdown should be the sum of the pressure of water and air in the tank. For example, a relay is set to 3 bars. Of these, 2 bars account for water, 1 for air.

How to avoid mistakes

Before increasing the pressure on the relay, you need to study the instructions for the pumping station - is it capable of supporting such parameters. If not, the pump will run continuously. The relay will not turn off the system because the desired pressure has not yet been reached. This situation may result in equipment burnout.

Do not tighten the nuts to the limit. This leads to a complete failure of the relay - it will stop working and automatically turn off the station.

According to the rules, the sensor is not installed at maximum performance. If you need to raise the upper level, it is better to buy a relay with higher maximum values. This will increase the service life of not only the sensor, but also the pump station.