Providing water to a private home is one of the very first problems that residents are trying to solve. Without a well and a pump, you cannot connect a washing machine or dishwasher, or take a shower without additional preparations. Pumping equipment in the country will not interfere, since in the summer you have to water the area daily. What to give preference to, a mobile pumping station or a stationary device, it is up to the owner to decide. To do this, you need to understand the principles of operation and features of the equipment.

Definition and purpose of a water pumping station

A well-equipped well or well is a big plus for a country house or summer cottage. Even better, if pipes are connected to the source and a pump is installed that delivers water directly to the house. This saves energy and time, and also makes people's lives more comfortable.

Most private house owners prefer pumping stations. This equipment can be assembled with your own hands, if you have technical skills - the scheme of the pumping station is quite simple. However, it is better to buy a ready-made device with factory settings and carefully tested before sending it to the buyer.

The pump station operates in automatic mode, so there is no need to constantly monitor on and off. The entire process is controlled by the automation unit. The system provides constant pressure, thanks to which you can connect any household appliances. The pressure drops are weak, so the technique works stably. Water can come from any source - a well, a well, a river, as well as a central water supply, if one is nearby.

Advantages of the pumping station:

- A correctly selected unit is able to provide water for a house, utility rooms and a vegetable garden. The main condition is a constant voltage in the network and well productivity, which allows pumping out the amount of fluid that is necessary for the needs of the territory.

- Power saving The unit automatically turns off when a certain pressure is reached.

- The presence of a hydraulic accumulator, which allows you to make a supply of water in case of a power outage or in other circumstances.

- Surface devices can pump water from the narrowest borehole thanks to a suction pipe.

- Factory settings rarely require correction, and installation is done as soon as possible. A person without experience can do this.

- With the correct connection and proper operating conditions, the device works for a long time, without requiring repair.

Disadvantages of the pumping station:

- High noise level. It is necessary to find a warm place away from living quarters, but such that you hear a little sound of a running motor in case of breakdown.

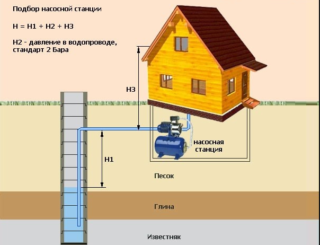

- Limited well depth - the device of water supply pumping stations does not allow to get water deeper than 9 meters without an ejector.

- If installed permanently, for the winter it will not be possible to pick up the device in the house, so the location of the station must be well thought out in advance.

- Fairly high cost.

The price of the device is due to expensive materials that last a long time and do not require frequent repair or replacement of parts.It is not recommended to buy pumps whose mechanical parts are made of plastic, since under the influence of solid fractions - sand or stones - the impeller quickly erases and fails.

Equipment device

A classic pumping station is arranged in one of two ways:

A classic pumping station is arranged in one of two ways:

- with vortex pump;

- with a centrifugal pump.

With the same performance, only the way the liquid rises from the depths is different. For a private house, medium or low power equipment is sufficient, depending on the number of residents and equipment.

There are also ejector devices that allow you to pump water from a depth of more than 10 meters. These devices are more expensive, but if the well is deep and the water is far away, it is more profitable to buy suitable equipment than to drill a new well.

According to the method of accumulating liquid, there are two types of stations - an obsolete model with a storage tank and a new sample - with a hydraulic accumulator.

A storage tank is rarely found on sale, since pumping stations require special installation and maintenance conditions. Water flows into the pipes from the tank by gravity, so the pressure in the tap is small, there is no way to fully use the shower or install, for example, a jacuzzi bath. The storage tank must be installed above the pump itself - it is not always possible to find a place for the bulky design of 200-300 liters. In addition, if the fill control sensor breaks, flooding is possible.

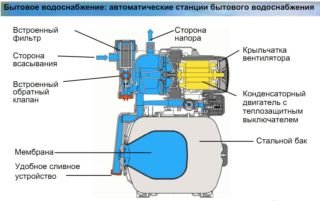

The hydraulic accumulator is a small container with a rubber membrane inside. Around her is air. When filling the pear, the air is gradually squeezed and pushes the liquid into the pipes. The device is equipped with a pressure switch, according to which the station turns on and off.

In addition to storage tanks, pumping stations are equipped with:

- electrical unit - cable, connector for connection, grounding terminals;

- control unit - pressure gauge, pressure switch;

- one type of pump.

An ejector - remote or built-in - is a separate equipment that can be made independently or you can buy a ready-made pump station with additional functions - a pressure and recirculation pipe.

Household models and working principle

The principle of operation of the pumping station is as follows:

The principle of operation of the pumping station is as follows:

- When the equipment is turned on, the impeller lifts the liquid in the direction of the outlet.

- Water rises along the suction line and fills the rubber membrane. A pressure is created inside that pushes the fluid into the outlet. Until the engine is turned off, the membrane remains full.

- Pressure control is carried out using a relay having certain settings. Visually assess the pressure using a manometer. The station turns on when the membrane is empty, that is, the pressure is minimal and in the house someone opens the tap. After reaching the upper pressure, the device turns off.

In addition to the main functions, the system is equipped with elements of protection against overheating, dry running, as well as filters from the ingress of solid fractions into the inside of the pump.

There are two types of pumping stations - industrial and domestic. Industrial work with large volumes of liquids, so the load on the system is large. Uninterrupted pumping is achieved thanks to the availability of redundant equipment and additional cooling devices.

Domestic pumping stations are a simpler type of device. By type of pump there are:

- self-priming;

- multi-stage;

- vortex;

- centrifugal;

- sewer.

The advantage of a self-priming pump is that it can operate when there is air in the system, although for some types this is a problem and the device turns off by itself. When working, they make a loud noise, so they are installed in a pit or in a separate isolated room. Water is taken from a depth of up to 9 meters.

Multistage stations are chosen if greater productivity is needed. They are less noisy, but more expensive. The more steps, the more expensive the design. Able to lift fluid from 8 - 9 meters.

A pump station with a vortex pump operates no deeper than 7 meters, but creates a strong pressure. If the water source is far from home, such a device is suitable for installation.

Centrifugal pumps are capable of operating at great depths and with liquids having different temperatures.

Sewer stations are installed in those places where it is impossible to carry out a gravity system. This is heavy equipment with various sensors and several pumps included.

There are also automatic pumping stations that do not have a membrane tank. These are compact devices designed for temporary use, for example, for watering the garden or filling the tank with river water for use in the country.

Criterias of choice

A huge number of domestic types of stations are presented on the pumping equipment market, which differ in technical characteristics. It is important to pay attention to the following:

A huge number of domestic types of stations are presented on the pumping equipment market, which differ in technical characteristics. It is important to pay attention to the following:

- power - there are models from 500 to 2000 W;

- productivity depends on power - the higher it is, the more water the station can pump out per unit of time; for a private house, you need to buy a device with a capacity of about 2000 l / h;

- accumulator volume - can be from 15 to 60 liters; the larger the capacity, the less likely the pump will turn on;

- the presence of protection against dry running and overheating - such functions sometimes save the device from combustion;

- materials for the manufacture of the casing and internal parts - cast iron, steel or plastic, in more expensive models the casing and the impeller are steel.

If it is necessary to place the device close to residential premises, since there are no other options, it is recommended to choose a cast-iron case - it dampens better than a stainless steel case, although the appearance of steel products looks more attractive. Inside, cast iron is coated with a protective layer against corrosion. The material is less susceptible to vibrations and therefore lasts longer than technoplastics. In addition, he is not afraid of mechanical damage.

If the well is Abyssinian, an ejector is needed, otherwise a simple, even very powerful station will not raise water. It must be additionally protected from pollution by installing a filter at the end of the pipe, otherwise it will clog up with dirt and the pump will stop working.

Features of installation and connection

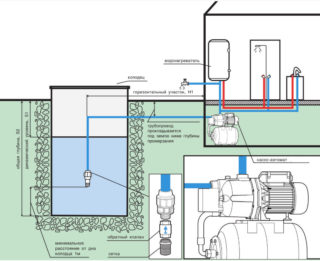

Before starting the installation, choose the place where the pumping station will be located permanently. Most often this is a basement, a warm barn or a pit near the well. In any case, the installation platform must be solid and level. It is best for this to make a concrete pillow on a certain elevation. In case of flooding, the pump will be safe.

The concrete slab and the device itself should not come into contact with the walls of the house, since vibrations occur during operation - this leads to the destruction of load-bearing structures and collapse.

The room must be heated. Condensate can accelerate the appearance of rust on the metal, and warm air dries up liquid droplets and maintains integrity.

If a special cavity is constructed for the pumping station in the ground - a caisson, it is made lower than the freezing level of the soil - about 2 m. The pit is dug up with the expectation that people will work in it if it is necessary to repair the device, so it is not recommended to do it closely.

If the room for the station is located within the house, and the equipment is very noisy, the walls must be insulated with special material.

It is not advisable to install electrical equipment in a special area inside the well. Water can rise high and flood the device, which after that will not work. In addition, it is difficult to repair something inside the well.The vibrations created by the surface pumping station gradually destroy concrete walls and joints between the rings. The well will fail faster.

Before filling pipes into the ground, you need to test the entire system for several days. If problems are found, finding them will be easier.

Cost of pumping stations

Imported analogues are more expensive - the prices for pumping stations of German, Italian and Japanese manufacturers are the highest. This is due to the use of quality materials for the manufacture of the housing and internal parts. Among the imported models you can find almost silent units.

High-quality products of domestic brands are also worthy of attention. If you choose expensive pumps from Russian manufacturers, you can count on a long service life and timely repair in service centers.