The pump station for increasing pressure in the water supply system (PNS) serves to maintain the pressure in the main water conduits and in the schemes for the non-centralized supply of drinking water. Equipment, including several hydraulic machines, provides water transportation from the point of intake to the place of distribution.

Purpose and scope

The main task of the complex is to maintain environmental parameters in the backbone networks. When opening the valve of the crane pressure decreases. As soon as the threshold value is reached, the pump automatically switches on. The cessation of water intake leads to an increase in pressure, when the Pmax setting is reached, the automation switches off the hydraulic equipment.

The main task of the complex is to maintain environmental parameters in the backbone networks. When opening the valve of the crane pressure decreases. As soon as the threshold value is reached, the pump automatically switches on. The cessation of water intake leads to an increase in pressure, when the Pmax setting is reached, the automation switches off the hydraulic equipment.

Domestic stations can be used for the needs of autonomous water supply at home and for irrigation of the site.

Depending on the purpose, the installations are:

- household pumps with low capacity - are used in the private sector to pump small volumes of water;

- production with powerful hydraulic machines that maintain pressure in the highways of cities and enterprises.

Domestic-type pumping stations increase the pressure in the water supply to provide water to residents of the upper floors. They are automatic and with manual regulation, are supplied complete and immediately ready for operation after installation. Installation is straightforward and does not need constant monitoring.

A sensor that monitors the decrease or increase in pressure in the system, depending on the regularity of water use, monitors the on and off of the pumps. The efficiency of the booster station is increased by multistage units operating in automatic mode.

With manual operation, visual control of the operating personnel is required, which monitors the pressure parameters and manually connects the equipment.

The principle of operation and arrangement of stations

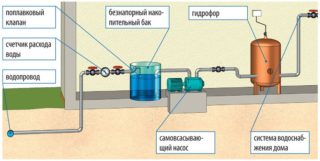

The main working blocks of the booster hydraulic installation:

The main working blocks of the booster hydraulic installation:

- automation, which monitors the change in pressure in the water distribution system, timely connecting or disconnecting the water intake;

- hydraulic machines;

- a water battery or tank designed to prevent damage from water shocks.

An emergency water tank reduces the number of connection cycles. The design consists of a cylindrical vessel, inside which a rubber bulb is placed. The elastic tank is filled with water when the pumps are running.

Types of stations

Industrial pumping stations are installed at enterprises responsible for water and heat supply in settlements and for the discharge of sewage, especially in cases where it is impossible to use the principle of gravity flow on horizontal sections of the pipeline. They operate automatically without the intervention of operating personnel.

There is a wide variety of species, each of which is used for its intended purpose: borehole and circulation, cantilever-monoblock and drainage stations, sewer hydraulic machines.

Criterias of choice

To raise the comfort of living in rural areas to the city level in the absence of trunk networks, allows the pumping station. With its help, water is taken and delivered from a well or other source. You can connect the unit to the water supply.

To raise the comfort of living in rural areas to the city level in the absence of trunk networks, allows the pumping station. With its help, water is taken and delivered from a well or other source. You can connect the unit to the water supply.

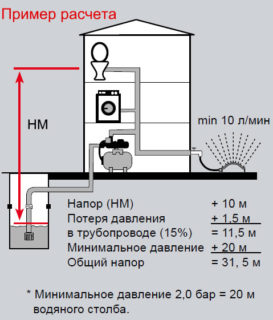

The power of the station is associated with its pressure, which determines the height of the water rise, and productivity - the volume of liquid that the device can pump over a certain period of time.Approximately one flow point accounts for 15 l / min.

The maximum rise shows which floor water can be pumped onto. Remoteness of the house from the station matters. Every 10 m of the horizontal section corresponds to a rise of 1 m from the surface. If the distance is 100 m and the height of the house is 10 m, then the productivity is calculated by the formula: 100: 10 + 10 = 20 m water column or 2 atm.

The choice of device design depends on the depth of water intake. With increasing depth, an installation with an ejector is used. It uses the energy of water raised to the surface. Part of it is returned to the ejector system located in the well. The volume of the raised liquid increases.

The larger the volume of the accumulator, the greater the supply of water will be created. With a power outage, half of it can be used up for strategic purposes. The air pressure in the tank is maintained at a level of 1.5 or 2 atm. With a decrease in this indicator, air is pumped using a pump.

The case is made of cast iron, steel or plastic. High hygienic properties of stainless steel make its use preferable.

A large assortment of domestic PNS is represented by domestic and foreign manufacturers. The Danish company Grundfos and the Russian Caliber enjoy a good reputation.

Features of installation and operation

Before switching on, the pump and the suction hose are completely filled with water. Pump up air in the accumulator to P = 1.5 atm.

When testing, open the valve in the tank and plug the device into a power outlet. After 2 or 3 minutes, the water should flow from the hose. If necessary, repeat the operation.

The automation settings are checked when connected. It must be triggered when the setpoints Pmax and Pmin are reached. If the water intake is turned off and the valve is shut off, the pump should not work longer than 10 minutes, as this will lead to its overheating and deformation of the elements.

Maintenance requires constant monitoring of the operation of the device so that in the event of an emergency it is possible to quickly take measures and minimize possible damage.

Advantages of stations for increasing water pressure

Using a garden pump with automatic control will not solve the problem of autonomous water supply. The system becomes vulnerable to water hammer caused by surges in water pressure. Sharp changes are associated with a change in flow. The advantage of a pumping station is its ability to prevent or level their effects. Repeated pressure surges reduce the service life of pipelines and valves. They disable connected plumbing.

The rubber bulb plays the role of a compensator. It is located in the accumulator. In the drainage mode, its expansion occurs, which dampens the pressure fluctuations. The second advantage of the pumping station is smooth regulation.

Elastic membranes are made of various materials:

- durable butyl products - allow you to pump hot liquids.

- ethylene-propylene pears - also tolerate high temperature, but have less strength;

- butadiene-nitrile universal products - used in the pumping of food products, liquid fuels, oils and water.

Pumping stations are equipped with a block that protects against dry running, as water helps to cool the device and acts as a lubricant. In-line coarse filters help extend the life of hydraulic machines.