Pumping stations - equipment designed to lift water from the depths of wells and wells. If a private house is connected to the central water main, they are used to maintain the necessary pressure of the water flow. Unlike submersible pumps, they allow you to maintain a constant pressure in the pipeline. In order for the water supply system to work round the clock without interruptions, it is important to correctly install a pump station to supply water to a private house.

The device of the pumping station

Thanks to the operation of the device, the water supply scheme can be made as branched as possible, facilitating the connection of various household appliances to it.

Thanks to the operation of the device, the water supply scheme can be made as branched as possible, facilitating the connection of various household appliances to it.

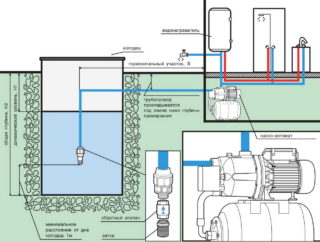

The following nodes are included in the station diagram:

- centrifugal pump lifting and transporting water;

- hydraulic accumulator, softening water hammer;

- check valve water intake system;

- pressure gauge for determining the degree of pressure;

- pressure switch for its control;

- Electrical engine.

Previously, instead of a hydraulic accumulator, storage tanks were used, but now such devices are practically not used.

Installation Rules

The connection diagram of the pumping station in a private house (piping) depends on the location of the installation, as well as on the level of freezing of the earth.

Choosing a place to install the device

The first thing to do is determine the location of the pumping station. It could be:

- house building (basement, underground);

- caisson - an insulated and waterproofed pit located below the level of freezing of the soil;

- shelf in the well.

When choosing, it is worth being guided by technical indicators - the maximum suction depth of the pump. In the wells, it is only possible to equip the caisson, since the station can lift water only from a depth of 9 meters. A camouflaged pit will also be required in the country house - with an external arrangement, the device can simply be stolen. You can also mount it on a shelf in the cottage, but for security you will need a steel cover that can be locked with a secure lock.

It is most reliable to install a water supply station in the utility room of a private house. The downside of this installation is the noise from its operation. To reduce the sound level, the device is installed on thick rubber, but this will not give complete noise isolation.

Wiring diagram

For the smooth operation of the station, it will be necessary to ensure a continuous supply of water from the source. When using system water supply all year round, you will need to worry about protection against freezing. To do this, dig a straight ditch from a well or a caisson to the foundation foundation of the house, into which pipes will then be laid.

Bury pipe sections below the depth to which the soil freezes. When forming a trench, it will be necessary to take into account the slope towards the water intake, so that excess water from the pipeline merges for the period of conservation.

In a situation with a close location of subsoil sources, pipes are installed above their critical level. The highway must be insulated or use a heating cable.

The electric motor of the pump has great power, so for the whole installation it is better to allocate a separate power supply line, make grounding, and also put a voltage regulator.

The tying of the pumping station in a private house is carried out in the following order:

- Mount the intake unit. To do this, connect by connecting to the outside of the pipe from polypropylene a filter from a metal mesh and a check valve.The latter is necessary for the stable filling of the pipeline with water. Its fixation is carried out by means of a coupling with an external thread.

- Install the hydraulic accumulator and control unit. They are best connected with a five-pin fitting mounted in a pressure pipe in a convenient location. A pressure gauge and a pressure switch are also installed on it, and a hydraulic accumulator is connected to the side inlet of the fitting.

- Consumers are connected to the pump installation, first, the distribution manifold.

- Before starting, the working part of the system is filled with water. To do this, unscrew the plug from the filler hole located at the top of the pump, or use a special funnel. Then the plug is put in place.

- Connect to power for a soft start and check the pressure and automation. At first, the water will go with air - the air jams formed during the filling of the pumping station are successful. A smooth jet without bubbles is an indicator that the system has switched to operating mode, you can use it.

After starting the station, water should flow from the outlet of the pressure pipe or open tap for two to three minutes. If this does not happen, the installation is turned off and water is added to the system, and then restarted. When the start-up of the equipment is successfully completed, it is necessary to “run in”, and then adjust the settings of the pressure switch and hydraulic unit.

When installing the surface parts of the device, it is taken into account that all additional devices are best installed using non-return valves or ball valves with an American. This is necessary for easy removal of the device during replacement or repair work, without the need to drain water from the pipeline.

The ability to drain water from the system is best foreseen in advance. To do this, create a branch in the pipeline by mounting a tee with a drain valve connected to it.

Common installation errors

If you poured water, but you can’t start the installation in any way - the water does not come in or goes jerky - you need to understand it. There are several likely reasons:

- There is no check valve on the suction pipe placed in the source, or it does not work.

- Somewhere on the pipe there is an leaky joint, air leaks through it.

- Plant productivity does not correspond to the amount of water consumed.

- Pipeline resistance is too high - you need a pipe with a large cross section or with smoother walls.

- The water mirror is too low.

- Not enough pump power.

Frequent shutdowns and starts occur as a result of improper installation of the hydraulic tank. The electric motor of the pumping equipment can break down due to interruptions in the power supply, and a redundant power supply can solve this problem. With frequent power surges in the electrical network, circuit breakers and stabilizers are needed.

To check the equipment for damage, test it by placing a short supply pipe in a container of water. If everything works, check the route, suction depth and check valve.

After connecting, the pumping station needs a systematic examination. It is necessary to constantly check the condition of the coarse filter and wash it if necessary. If this is not done, the productivity of the station will decrease, the water will go jerky. If the filter is completely clogged, the pump will idle and the station will shut down. How often you have to clean the filter part depends on the amount of impurities in the water.