It is very difficult to provide the most comfortable accommodation in a private house without proper water supply. To dig a well that reaches aquifers suitable for consumption does not work out in every area. Therefore, drilling is the best way to obtain drinking water. However, installing a pump into a well with your own hands is often difficult. This is a responsible process, the accuracy of which affects the subsequent operation of the entire system.

Preparation of materials and components for installation

In order to avoid annoying misunderstandings or hitches during installation work, you must first prepare all the consumables that may be needed during installation. These include: clamps, a non-return valve and a stopcock, fasteners, an electric cable, a pressure gauge and a number of other details.

- Special double vinyl insulated power cable for long-term use in a liquid environment. It should lie freely, without stretching, and ideally be solid, without joints along its entire length, so it is better to take the meter with a margin. The cross-section of the wire to eliminate overload is selected according to the passport data of the unit. If the power cord requires extension, special types of couplings are taken to completely seal the joints.

- To supply water, metal-roll pipes or low-pressure plastic HDPE are used. When doing the installation of a borehole pump with your own hands, it must be taken into account that the pressure is of sufficient power. A product with a cross section of 32 mm or more is placed. It has the least hydraulic resistance and is therefore more efficient. The joints are fastened with flanges installed bolted up. For threaded connections, you will definitely need a winding reinforced with silicone sealant with a sealing or FUM tape.

- It is better to take a safety cable in the plastic sheath preventing corrosion processes. It should correspond in length to the depth of the well, plus a margin for fasteners. Fixing clamps are taken with the calculation of the mass of the entire system multiplied by ten.

- To install the pump in the well yourself, you need to pay attention to plumbing fixtures. In the work, adapter fittings are required to connect parts of different diameters and futorki with inserted metal sleeves for joining with pipes.

- The head is necessary to protect the structure from foreign objects entering it from the outside. On its lower part, holes are made for the pressure hose, cable and safety cable. There is also a carabiner for attaching system elements.

- The power cord, safety harness and pipe are fastened together in increments of 70-130 cm. The first fastening is carried out at a distance of 0.2 m from the nozzle. To make the connections, insulation tape or plastic ties are used.

For operation of the water intake system, a check valve is required. Before you begin installing the submersible pump in the well, you need to make sure it is available. Do-it-yourself mechanism that prevents the reverse movement of water to the equipment is not difficult to install. It can be purchased at any specialized store.

At the exit, a ball valve is installed to check the presence of water in the system and adjust its pressure. Connecting the device to the power grid “on dry” is prohibited.

Preparing the pump for installation

The assembly of all elements before installation occurs in a strictly defined order.Initially, the presence of a check valve is checked, in its absence it is necessary to purchase and install this mechanism yourself. Next, the transition fitting with a foot is mounted for connecting the pipe. Their sizes should fit the details. Joints are sealed to prevent leaks.

- The insurance is attached to the pump for two eyes, symmetrically located on both sides of the device, and is fixed with special clamps.

- A sleeve is inserted into the polypropylene pipe and the fitting is assembled. Then, this design is connected to the pump and the fitting units are pulled. When installing the crimp ring, you need to monitor the correct location of the internal teeth, and try not to damage the rubber seal.

- In case of insufficient length, the cable of the device is extended. The main attention should be paid to the tightness of the junction, otherwise the contacts will oxidize, and the installation of the deep pump in the well with your own hands will end with a short circuit.

- After preparing all the individual components, the electrical wire and insurance are connected to the pipe. For this purpose, plastic clamps are used, located at a distance of a meter from each other. The reverse end of the cable catches on any large fixed object that can hold the assembled structure.

- The last fitting is installed, which will be needed to fix the tip after the device is immersed in the well and pieces of the excess pipe. After this event, the accuracy of the assembly of all elements is checked to eliminate possible problems.

The additional connection of the accumulator to the submersible pump positively affects its service life. This device has a water supply that can satisfy one-time needs of the user. The number of connections of the pump itself is significantly reduced, which has a positive effect on its life.

Installation work

There are many rules and recommendations regarding the installation of a submersible borehole pump, including with your own hands. The regulations indicate that this device should not be in contact with the bottom of the intake well, and at the same time, the device should be submerged more than a meter under water. Well filling is not constant. It can vary depending on the season and the intensity of the fence.

There are many rules and recommendations regarding the installation of a submersible borehole pump, including with your own hands. The regulations indicate that this device should not be in contact with the bottom of the intake well, and at the same time, the device should be submerged more than a meter under water. Well filling is not constant. It can vary depending on the season and the intensity of the fence.

- The higher the unit performance parameters indicated in the passport, the greater should be the depth of immersion. The best way to determine the location, which is most often used in practice: the device is lowered on a safety cable to the bottom of the water well, and then raised to 2.5-3 m and temporarily fixed, run. If the equipment operates without deviations from the norm, it is fixed in this position.

- This method is used when installing units in wells up to 16 m, for deep devices calculation is done differently. The distance from the mouth to the water mirror (dynamic level) is subtracted from the total depth of the source from the head to the bottom. The resulting difference is the magnitude of the location of water during active well operation. According to the norms, this gap is reduced by 300 mm from the bottom and 100 mm from the top. In the remaining segment, the apparatus should be located.

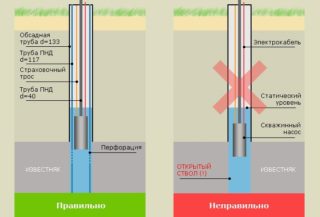

- Before lowering the pump into the well, you yourself need to check the casing for the presence of irregularities, contractions or distortions. They can affect the quality of the equipment and cause the unit to fail. Preliminary washing and cleaning of the mine will make it possible to preserve the main components of the structure. The steps of this process can be seen in the video.

- Before lowering the unit onto the pipe, a cap is put on through the o-ring. If the preparatory work is done correctly, no problems should arise at this stage.However, if the pump stops and does not go, then there are foreign objects in the well.

Installation of equipment is carried out only after all calculations and drawing up a scheme. The work should involve from 2 people or more. When conducting assembly and installation work in the country, it is worth using a voltage stabilizer. This will help protect highly sensitive equipment from power surges.

Possible mistakes and how to avoid them

For a person who decides to install a submersible pump into the well with his own hands, the main task is to take into account all the nuances and prevent misses, most often made by others.

- The pump power parameters should correspond to the depth of the well. Excessive equipment quickly breaks down.

- Inaccurate calculations when determining the place of suspension of the device can lead to the fact that it remains without cooling, and overheating is one of the main reasons for the breakdown of units.

- Improper fixing of the cable may lead to the breakage of the device. The same result is to be expected if the insurance material is chosen incorrectly.

- The pressure hose must withstand the pressure created in the system, so it cannot be less than the pump outlet.

- When building the cord, an electric cable is taken, the cross section of which corresponds to the power of the device. Otherwise, the operation of the equipment will inevitably result in overheating and short circuit.

The absence of a stabilizer or automatic relays leads to the risk of equipment overload during power surges. Ideally, it is better to install an automatic control system. But a cabinet with control and protective devices that can track the operation of the system may be disadvantageous in a private house.