Installation of a submersible borehole pump requires special care and verification of all calculations from the installer. Also, for this, certain skills are needed, without which the procedure cannot be completed without errors. It is necessary to familiarize yourself with the sequence and installation rules of pumping equipment even if you plan to entrust the work to specialists.

Choosing the right pump

In order for the equipment to serve without interruptions for many years, it is necessary to correctly install it and use a suitable pump, the technical characteristics of which are optimal for an existing well or well.

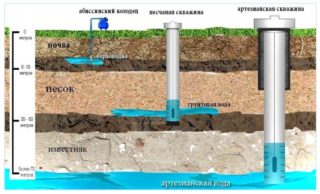

The best choice for a well in its own area is a centrifugal type model. Vibration marks can cause excessive fluctuation in the source, which will lead to the destruction of not only the soil, but also the pipe, which serves as the basis for the well. Such models are not recommended for installation “on the sand” - such wells are less resistant to impact than artesian ones. You should remember about other features of the pump:

- The power of the equipment should correspond to the size and depth of the well.

- Each model in the technical documentation has recommendations for installation at one or another depth. If you use a pump designed for 50 m at a depth of 60 m, it will use up a working resource 10 times faster.

- If the well was installed on its own, it is better to use a special model for an artesian well, which will be less destructive, because professional drilling is still different in quality from amateur drilling.

- you need to take into account the diameter of the pump - it is selected based on the size of the casing.

Together with the choice of a submersible pump for a well at the time of creating the installation diagram, it is necessary to immediately take into account the diameter of the pipe. The best choice is a four-inch material, since it is easier to choose a pump for it than for a three-inch one.

Preparation for installation and selection of related materials

For quick installation, you will need the following tools and supplies:

- additional polymer cable for launching the equipment;

- flexible rubber for depreciation of equipment during descent;

- an electric cable of sufficient length that will not be tensioned at the maximum descent of the pump;

- plastic pipes for water drainage to the common pipeline system - with a diameter of at least 3.2 cm;

- flanges for connecting pipes, which are characterized by increased strength than threaded elements, but you can also use them;

- cable clamps;

- non-return valve, as well as a stopcock for the pipe;

- steel mount;

- manometer.

Additionally, wire and electrical tape will be required for temporary mounting of various elements.

It is important to consider the characteristics of the water pipe. If the well is up to 50 m deep, the pipes must withstand a pressure of 10 atm. If more than 50 - at least 12.5 atm. When using wells with a depth of more than 80 m, pipes should be designed for 16 atm.

Step-by-step pump installation procedure

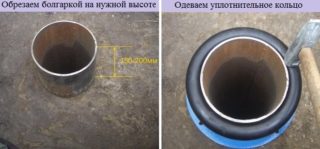

After preparing all the tools and supplies, you can begin installing the submersible pump in the well. The main element to work with is the casing. Install it in the well immediately after drilling. A pump is lowered into it during installation.It is important to make sure that the well maintains evenness over its entire length, it has no narrowing and curvature.

Installation steps:

- Determination of the difference between the internal cross section of the well pipe and the diameter of the body of the launched equipment. If the pipe comes back to back, any of its imperfections can cause equipment damage. If the pipe size is too large, it will not be properly cooled and will soon fail. Clarify the exact clearance parameter in the documentation that accompanies the equipment.

- Fastening all pipes and cords. Connect all the elements of the hydraulic line using flanges.

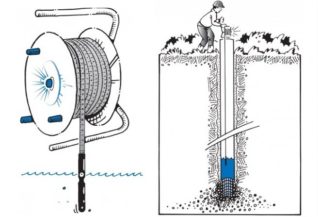

- The descent of the hydraulic machine into the well using a polyamide cord. The cord is tied to the body, then gradually lower the equipment down. The cord should ideally support a weight that is 5 times the weight of the hydraulic machine. The cord assembly must be at least 10 cm from the inlet of the machine, and the ends must be cut off.

- The use of a spring suspension when mounting to a depth of less than 10 m. If the pump is installed at a specified depth, use a spring suspension mounted on the housing. It can be a medical tourniquet or a piece of rubber. The wire and metal cable are not suitable for these functions, as they can break the mounts on the machine body.

- The use of additional elements during the descent. Together with the pump, the power cord and the metal-plastic pipe, which is connected to the pipe, are lowered into the casing. They are fastened with insulating tape in a step from 70 to 130 cm. The first bundle of electrical tape should be 20 cm from the discharge pipe.

Particular attention must be paid to the descent of the pump. It is very important that its walls and body remain intact. Jerks and bumps on the pipe must not be allowed. After the machine is installed, the upper end of the suspension is attached to the crossbar mounted on the ground. It should not be mobile.

Pump start algorithm

As soon as the installation of the deep pump in the well is completed, proceed to the first connection of the equipment. It is very important to correctly attach all the elements, otherwise it will affect the service life of the equipment:

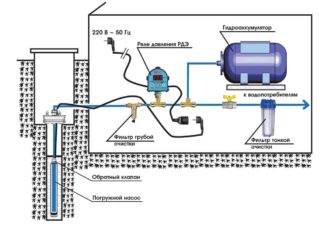

- The end of the pipe connected to the nozzle is fixed to the base plate of the well.

- If there is no check valve in the design of the hydraulic machine, it is purchased separately and installed on the discharge line.

- Install valves on the discharge pipe, an outlet elbow and a pressure gauge that will allow you to keep the pressure level under control.

- Connect the elbow extending from the pipe to the pipeline, which will distribute the liquid at the points of consumption.

After all the manipulations, you need to measure the resistance of the motor winding and the electric cable, which is immersed in a liquid medium. To do this, use a megaohmmeter. Now you can connect the pump to the control station and conduct a test run of the equipment.

It is impossible to call the installation of pumping equipment in a well or a well a simple procedure. It requires great care and responsibility and, unfortunately, is not available for execution by beginners who have never done anything similar.

Source Depth Determination

For adequate operation, it is necessary to fix the pump in the well at a certain depth. For this, it is important to take into account the dynamic and static level of the liquid medium:

- static - the level at which water is in a calm state relative to the surface of the earth;

- dynamic - the level to which water drops when it is pumped out.

For the pump to work without interruptions and not to overheat, it must be installed at least 30 cm below the dynamic level. Even better if the equipment is installed at a level of 2-3 m from this mark. But we must not forget that the distance to the bottom should be at least 1 m, and preferably 2 m.

Common mistakes and their elimination

You can improve the quality of work performed by familiarizing yourself with typical errors in advance. This will save the installer from unforeseen expenses and other negative aspects. The most common mistakes:

- use of power cable with the wrong cross section;

- incorrect determination of the height of the pump suspension;

- wrong choice of control automation;

- lack of a surge protection element;

- small diameter of water supply pipes;

- lack of a check valve in the system.

You can reduce the risk of errors even at the stage of preparation for the installation of the pump. If there are difficulties with the choice of components and consumables, you should consult a specialist.

Errors in the installation of equipment make almost all fans. They have to be fixed, the main thing is not to rush and carefully study the problem once again.

Installation on your own or ordering services from specialists

When installing a borehole pump, various difficulties can arise. If a person has experience in the construction of hydraulic structures or other similar structures on the site, there is experience in designing similar systems and an understanding of the operation of certain elements, you can cope with the task on your own. If you encounter difficulties, you can always turn to the help of the Internet.

If there is no similar experience, and a person has no idea how the hose differs from the nozzle, then it is better to contact specialists. The cost of services can be high, but the craftsmen will do everything right and reliably.

An important factor is what plan the well is being equipped with. If this is an artesian well with a depth of 70-100 m, it is better to contact specialists. It is very important that the well itself be equipped with a professional team. After all, vibrations from a running pump can seriously damage any amateur building that is not designed for certain loads.