Reverse osmosis filters are a reliable way to purify water. They are used in everyday life and in enterprises for desalination of salt water. The essence of the process is to pass the fluid through a microporous membrane so that all salts remain on one side, and water molecules on the other. In this case, an integrated approach is preferable to prepare the dirty liquid for filtration through the membrane. This will increase the service life.

The purpose of the reverse osmosis membrane

Reverse osmosis systems are popular and are the main competitors to distillation plants. The reverse osmosis method allows you to get cheaper drinking water. The developers went further and created mineralizers that restore salts that are filtered in the process. As a result, the output is real mineral water.

Bacteria and viruses cannot pass through the microfilter, but this is more dependent on the size of the cells. Here it is necessary to distinguish between nanofiltration, ultrafiltration and the principle of reverse osmosis: with nanofiltration, the pore size is 0.001 microns, with reverse osmosis 0 0.1 microns. During ultrafiltration, dissolved salts pass through the membrane, but microorganisms are retained.

Heavy metals also cannot pass through cells due to the huge size of the molecules. Lead, for example, is not felt at all in drinking water, but accumulating in the brain tissue, over time, can cause neurological diseases, and in children a mental retardation.

Reverse osmosis membranes are used in the medical, food industry, as well as in the production of alcoholic products. Powerful plants filter the liquid at water spills.

Device and principle of operation

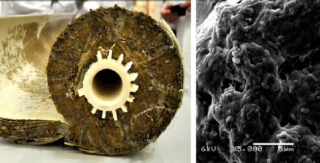

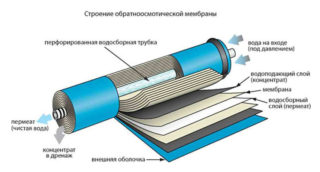

The main element of reverse osmosis filters is a semipermeable membrane - a special material is located around the hollow tube in several layers. Manufacturers have improved the design and now all harmful substances are washed off into the sewer. For comparison, in other filters they accumulate inside. This happens with the help of forced fluid flow. Thus, the filter itself extends the service life. The flask for a reverse osmosis membrane changes once every several years, depending on the quality of the product and the amount of fluid passing through the pores daily.

The main element of reverse osmosis filters is a semipermeable membrane - a special material is located around the hollow tube in several layers. Manufacturers have improved the design and now all harmful substances are washed off into the sewer. For comparison, in other filters they accumulate inside. This happens with the help of forced fluid flow. Thus, the filter itself extends the service life. The flask for a reverse osmosis membrane changes once every several years, depending on the quality of the product and the amount of fluid passing through the pores daily.

The material used is polymers. One of them, aragon, increases the amount of easily assimilable calcium, aragonite, in the filtrate. The basis for any filter is cellulose acetate, which is combined with polypropylene. This is the cheapest option. There are more expensive ones that withstand exposure to chemicals and heat. Ceramic membranes are the most resistant; PVDF and PAN products are inferior to them.

For the normal functioning of the membrane, several rules must be observed:

- system pressure from 3 to 5 atmospheres;

- fluid temperature;

- timely filter replacement based on manufacturer's recommendations.

People living in high-rise buildings need to additionally install a pump to increase pressure, otherwise filtration will not be effective. Due to the very small size of the cells, the liquid cannot pass through them on its own. Dirty water must be pressed under pressure. On high floors, it can be weak.

In domestic installations filtering cold liquid, an increase in temperature above 40 degrees can cause damage to the pores due to shrinkage of the material and the failure of the membrane.

The reverse osmosis membrane body is flushed simply: you need to lower the pressure and wait until the accumulated dirt is washed away by the stream. Sometimes a weak hydrochloric acid solution or special flushing liquids are used.

For each type of filter, its own pressure is determined, so when installing, you need to read the instructions or trust the work to professionals. With proper use, the membrane, depending on the brand of the manufacturer, lasts from 2 to 4 years.

Many potential buyers are interested in the question of what percentage of clean liquid can be obtained from the total amount of water used. Previously, this figure was about 30%, the rest of the liquid went into the sewer as unsuitable for consumption. Now we can talk about 85% of the total consumption, but this indicator needs to be specified when choosing - it is different for each manufacturer.

Criterias of choice

First of all, you need to take water for analysis in order to know the composition of the liquid to be cleaned. Since the membrane filter has a different pore size, it is important to know what substances you need to protect yourself from - mineral or organic, heavy metals or bacteria.

There is such a structural element as a drainage flow restrictor - this is the second important point that reduces fluid flow. It is selected depending on the membrane performance: for 36 gallons - 300 ml / minute, 50 gallons - 350 ml, 75 gallons - 420 ml, 100 gallons - 550 ml.

One of the selection criteria is price. Reverse osmosis plants are not cheap, so at the initial stage, people try to save. This is the wrong approach, as cheap installations are usually expensive to maintain. Before buying, you need to find out how often you need to change cartridges and how much they cost. In expensive models, replacement is less frequent, but the installation itself requires more serious costs.

Installation Features

When installing filtering equipment, the master does all the work, but later the cartridges will have to be changed on their own. This is a simple process, and most membrane filters fit the rest of the models. For example, you can put the Atoll membrane on a Geyser installation and vice versa.

Change the membrane filter when the machine slowly begins to accumulate water. If at first the tank was filled in an hour, then in a year and a half it takes 4-5 hours.

The membrane is between a mechanical filter and a carbon filter. The instructions describe this in detail. Also, the master at the first visit can show the replacement process, and the owner can try to pull out the case and put it back.

Operation and maintenance

The main thing in operation is to properly adjust the pressure in the system so that the filter does not clog and soften. Expensive reverse osmosis membranes last longer, they can be descaled, which many people do so they don’t have to buy a part again.

You can clean the membrane from the biofilm yourself using conventional detergents, but you need to do this regularly so that the organics do not penetrate all layers of the filter. If the mucus clogs the pores and the membrane does not function, you need to carry it to a specialized company, where all layers will be cleaned with chemicals. Chlorine dioxide is recognized as the best reagent. It has a prolonged action and after its use for a long time the washing of the membrane is not required. The substance is completely safe for drinking water.

The prices of the membrane for the reverse osmosis filter differ dramatically, since the products have different capacities. More economical ones are more expensive, membranes made of durable materials are also not cheap and will last longer than usual.