To save on energy consumption and eliminate pressure fluctuations in pumping units with hydraulic accumulators, a special separating element is used - a membrane. For long and uninterrupted operation of the equipment, it is important to know the design characteristics and operating rules of this part.

Purpose and principle of action

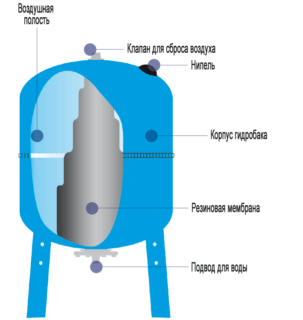

The purpose of the device is the separation of the inside of the tank into two chambers: air and water. It works as follows:

The purpose of the device is the separation of the inside of the tank into two chambers: air and water. It works as follows:

- Water is pumped into the membrane "bag", and the air between it and the walls of the device is compressed.

- When the maximum permissible pressure indicator is reached - for household appliances it is 1.8–3 atmospheres - the pump will shut off. The value must first be set on the pressure switch.

- The liquid enters the water consumers with the necessary pressure due to the action created by the compressed air inside the accumulator.

- After reducing the pressure to the lowest value, the pump will automatically turn on to draw water.

Such a scheme eliminates the differences in the pressure of the water and ensures stable operation of the system. Electricity consumption is saved and the period of operation of the equipment is increased, since the pump is switched on much less frequently. The use of a hydraulic tank with a membrane in the water supply network is also good because it minimizes the sharp pressure drops that occur when the pump unit is started.

Varieties and selection criteria

Details that look like a medical heating pad are installed in small accumulators - not more than 100 liters. In large hydraulic tanks - over 100 liters - the diaphragms are similar in shape to a bottle or pear. All these options in volume can be flat or balloon. The principle of operation for different types is similar.

When choosing a membrane, it is also taken into account that the products differ in the purpose of the hydraulic tank:

| Characteristics | For water supply | For heating |

| Colour | White | The black |

| Production material | Natural or bottled rubber | Temperature resistant EPDM or SBR rubber |

| Temperature (° C) | from 0 to 70 | from -10 to 99 |

| Maximum pressure (bar) | 7 | 8 |

Rubber is less resistant to low and high temperatures, but it is immune to the effects of bacteria, mold and fungus. These properties are important for maintaining the quality of drinking water. In no case can tanks with SBR diaphragms be used to connect to water mains. Styrene-butadiene rubber is a non-food material. It can be used exclusively in liquid storage tanks for technical use.

There are other ways of classifying membranes for hydraulic tanks, which should be considered when choosing.

By size

Dimensions are very important: if an error occurs, a worn part cannot be replaced with a new one. When evaluating the following criteria:

| Capacity (L) | Overall dimensions (mm) | ||

| Flange Size (Inner / Outer) | Length | Section | |

| 0,16 | 45/65 | 65 | 58 |

| 2–3 | 45/65 | 135 | 80 |

| 5–8 | 45/65 | 155 | 105 |

| 8–12 | 45/65 | 200 | 115 |

| 12–18 | 45/65 | 265 | 135 |

| 24 | 80/110 or 90/120 | 260 | 200 |

These indicators should be indicated in the technical documentation for the hydraulic accumulator.

It is important to consider the attachment of the diaphragm. It is usually carried out at the bottom of the tank through a flange. But in volumetric devices, called walk-through, it also provides for mounting from above. A hollow rod with a sealing element on one end and a thread on the other passes through an opening in the upper part of the membrane. The threaded end is brought out of the tank and attracted to the last nut.In fact, the outer part is a threaded fitting that can simply be plugged or installed on it a pressure switch and / or pressure gauge.

By interchangeability

Manufacturers produce two types of expansion membrane installations - with removable and stationary diaphragm. The first ones are more expensive, but they can be replaced in time in an element if breaks occur or it is deformed. The second is inexpensive. But in this case, the replacement of damaged parts and the resumption of the water supply system are not provided.

It is rational to give preference to the first type of hydraulic accumulators. Otherwise, the device will work as long as the diaphragm can withstand.

Replacing a worn part is easy, you can do it yourself, the prices of rubber parts are relatively low. They depend on the volume of the element, material of manufacture and manufacturer. Prices for the Gileks membrane for a hydraulic accumulator start at 600 rubles, the most inexpensive replacement parts for the Aquasystem cost from 260 rubles, for the Reflex from 1100 rubles.

Features of the installation when replacing

The membrane in the hydraulic accumulator is a consumable item. Over time, it becomes worthless, and replacement is required if the design of the device provides such an opportunity. The part wears out due to uneven pressure in the system, with continuous compression and tension, friction against other elements. Systematic and sharp temperature changes, exceeding pressure indicators also do not contribute to an increase in the operating life. According to manufacturers, it averages five years, but the impact of negative factors is difficult to avoid. In fact, at best, the membrane serves three years.

How to determine that a rubber bulb for a hydraulic accumulator requires replacement:

- the pump fails, frequent starts and stops occur;

- gauge indicators are jumping;

- leaking nipple;

- tap water flows in intermittent streams;

- there is leakage behind the air valve.

In most of these malfunctions, in most cases, the wear of the diaphragm is to blame, but sometimes there are breakdowns in the case. Before replacing the membrane, check it for defects.

To change the diaphragm, it is first necessary to turn off the power and release the pressure in the system, as well as drain the remaining water from the hydraulic tank.

The following actions are as follows:

- Remove the bolts, remove the flange and remove the damaged diaphragm from the special hole in the lower part of the housing.

- Inspect the tank for integrity, dirt, and corrosion. Rinse and drain.

- Install the replacement part.

- Screw the flange into place, pump air to 1.4 atmospheres.

Then connect the power and water, check the operation of the system. After all the manipulations, the battery is ready for use.

It should be noted that products from different manufacturers are not interchangeable. They differ in dimensional indicators.

You can change the diaphragm with your own hands and without resorting to specialists. But only if all the norms and requirements of assembly or analysis are observed, it is possible to carry out work at the professional level. If it is impossible to replace, the torn membrane is sealed with special glue or vulcanized. This will extend the operational period of the element, but soon it will still have to be changed. However, repair work prolongs the life of the device with a fixed diaphragm.

Terms of Use

In order for the tank diaphragm and the device itself to serve for a long time, you must adhere to the following recommendations:

- Perform a monthly inspection and battery check for regulatory compliance. The latter are individual for each drive model.

- If you do not use the hydraulic tank, keep it in a dry place, avoiding contact with heating devices. Otherwise, the material of the diaphragm may become dry, which will lead to its destruction.

- Check for corrosion and smudges at the joints and on the hydraulic accumulator housing.

- Periodically measure the air pressure in the product and monitor its stability.

- Check the integrity of the diaphragm approximately every six months.

In the event of malfunctions in the device, immediate troubleshooting is required to avoid aggravation of the situation. Otherwise, you can bring the device to a condition that cannot be repaired.

When the pressure device is operated with a hydraulic accumulator without a membrane, the load increases and wear is accelerated. The pump constantly turns on when the tap is opened. This increases power consumption and the risks of water hammer. A high-quality diaphragm will help protect equipment from these troubles.