A manometer is a device for measuring the pressure of water in a water supply system. With its help, accurate indicators of the working environment in any section of the pipeline are obtained. Depending on the operating conditions, several types of such sensors are distinguished.

Pressure gauge device for measuring water pressure

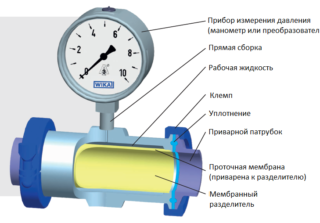

The pressure gauge has a simple design. The device distinguishes between the case and the scale on which the measured values are marked. In the housing is a tubular spring. It can be replaced by a two-plate membrane. The manometer has a holder, a sensitive element and a tribo-sector mechanism.

The arrow of the device is an indicator. She can make one revolution around its axis. Gears are used to transmit rotation to the arrow. In the design of the device there is a gear sector and a leash. Between the gears and teeth of the device is a special spring, eliminating the possibility of a dead stroke.

Pressure gauge classification and principle of operation

Depending on the features of the device, pressure measuring devices are classified into the following types:

- Piston They include a cylinder in which the piston is located. During operation, the medium acts on one part of the pump, and on the other, the load presses. The slider moves by moving the arrow. It shows a certain value on the scale of the device.

- Liquid. They contain a tube with a liquid and a movable plug. When using such a device, the working medium presses on the plug, changing the liquid level in the tube. The arrow of the device is set in motion.

- Deformation. There is a membrane inside such products, which, when deformed, activates a pointer above the scale.

Modern pressure measuring devices are divided into mechanical and electronic. In the first case, the design of the device is as simple as possible. The electronic pressure gauge contains a contact assembly capable of more accurately measuring the pressure of the medium. Such devices are widely used in industry. They are used as reference models for checking pneumatic components and adjusting regulators in various automated systems. Many electronic pressure gauges store data on peak pressure values for a certain period of operation.

Depending on the features of the work, the devices are:

- Stationary - install only on certain units. It will not be possible to dismantle such pressure gauges. Often, a water pressure regulator is used with them.

- Portable - can be installed on different units and used in various systems. A distinctive feature of the models is their small size.

Many of the pressure gauges for measuring pressure are used in heating systems of country houses and apartments of multi-storey buildings. Others are used to service industrial facilities.

Mounting Features

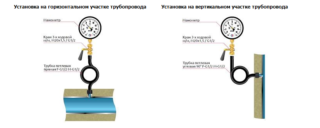

Installation of the pressure gauge is possible only at the facility with vented pressure. The device is installed in the working position. Usually it is spelled out in the instructions. It also indicates installation tolerances. Installation of the pressure gauge is carried out using a wrench. In order not to overload the device case, it is necessary to ensure that the tightening torque does not exceed 20 N * m.

You can install a manometer to measure the water pressure in the water supply in the following ways:

- Straight. The device is mounted in the places marked in the design documents, for example, before and after valves. An adapter is located at the installation point. It is connected to the pipeline by welding or screwing.The pressure gauge is installed directly in those cases when the system is stable, without pressure surges.

- Using a three-way valve. If the measurement data must be checked for atmospheric pressure, a three-way valve is installed for this purpose. Air is supplied through it. Replacing the pressure gauge installed in this way does not require interruption of the medium supply.

- Using impulse tube. It protects the pressure gauge mechanism from pressure drops. To install the device, you must use an adapter. Then the pipe, the three-way valve and the sensor itself are placed on the pipeline. This method is used in cases where the working environment has a working temperature that exceeds standard values.

To ensure stable operation of the pressure gauge for measuring pressure and to reduce the risk of malfunctions, observe certain installation requirements:

- Installation is carried out in such a way that it is easy to take measured values, carry out maintenance and repairs.

- If the pressure gauge is placed at a height of 2-3 m, the diameter of the housing should be more than 160 mm. Installation of the device to a height of more than 3 m is prohibited.

- A quick check of the pressure sensor can be achieved by installing a three-way valve in the design, which should be located between the pipe and the pressure gauge.

- When installing equipment in conditions of possible exposure to external adverse factors (high temperature, precipitation), it is necessary to create additional protection for the device. Siphons and buffer elements are selected for this task.

- Prevent freezing of the sensor allows its thermal insulation.

- During the connection of the pressure gauge, the gas that has penetrated the system must be vented. To do this, the fixing nut on the fitting is not slightly twisted.

Measuring equipment that does not pass the test and does not have a sealed seal on the housing is not allowed for use in communication networks. After the expiration of the test period, the sensor is removed and sent for diagnosis. If there is a crack on the glass of the device, or if visible damage has appeared on the case, the sensor should be disposed of.

The meter is installed in an upright position. Due to this, a normal reading of the data is ensured. The sensor scale can have a slope of no more than 30 degrees. The appliance must be well lit and protected from sunlight. It is undesirable to install a device whose arrow does not return to its original position after being turned off.

The meter is installed in an upright position. Due to this, a normal reading of the data is ensured. The sensor scale can have a slope of no more than 30 degrees. The appliance must be well lit and protected from sunlight. It is undesirable to install a device whose arrow does not return to its original position after being turned off.

After installing the device and putting the system into operation, do not immediately load it. It is better to raise the pressure gradually, avoiding sharp pressure surges. Such measures can extend the life of the sensor.

When installing a manometer for measuring pressure, the tightness of the connection between the measuring device and the fitting is checked. For this, FUM tape or thread is usually used. To make the docking place more reliable, use a sealant. All products must comply with the operating conditions. For example, for superheated steam with a temperature above 130 degrees, it is unacceptable to use FUM tape, which is designed for a maximum heating of 95 degrees. Some installation companies use tow as an insulator, which should not be allowed.

Pressure gauges for measuring pressure in the water supply network are not worth repairing on their own. When choosing the type of device, it is important to study the communication parameters in which it will be used.