Many owners of country houses or cottages equip an autonomous water supply system in their personal plot. It has many advantages, but its contents are quite troublesome. The arrangement of the water intake point requires the mandatory installation of a special protective device - the cover.

Why do I need a cover for a well

A cover for a source or a head is a protective device that prevents foreign objects from entering the well shaft from outside. If you neglect the installation of such a design, the life of the well or well will be reduced.

Most often, the tip is used to reliably seal the mouth of the water intake point. The main purposes of its use:

- Increase in the total debit of the water intake point.

- Providing maximum protection, which is especially important when the house has small children and pets.

- Safety during the installation of equipment.

- Prevention of sand and soil particles, leaves, dust, small insects, precipitation, etc. getting into the mine and pipe.

Despite the simplicity of the design, it performs a large number of functions that not only extend the life of the source, but also prevent tragic events.

Types and design features of the well cover for the casing string

Well covers are divided into several types, depending on the material of manufacture. The following materials are used for production:

- plastic;

- aluminum;

- cast iron;

- mixtures of plastic and metal in different ratios.

- Cast iron

- Aluminum

- Plastic

It is preferable to use a cover made of aluminum, since the device is fixed with tightening bolts. When tightened, plastic can behave unpredictably, cast iron can also burst.

Most modern covers are equipped with special eyes, the main task of which is to fasten the safety cable for the deep water pump. This is very convenient, because during operation it simplifies the implementation of preventive maintenance.

Most modern covers are equipped with special eyes, the main task of which is to fasten the safety cable for the deep water pump. This is very convenient, because during operation it simplifies the implementation of preventive maintenance.

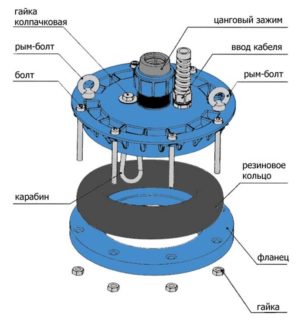

All types of covers have a special hole for the input of the power cable. Air movement in the barrel is ensured by the presence of a ventilation valve in the housing. If necessary or desired, this valve can be plugged.

Protective products are universal, designed for casing pipes of different diameters, or special for certain pipe diameters: 133 mm, 127 mm, 125 mm, etc.

Each cover must be equipped with grounding.

The upper part of the case opens without much effort, which greatly simplifies the operation process.

Design features of the heads for the well:

Design features of the heads for the well:

- Heads from different manufacturers may have, albeit minor, but differences in design.

- Some models are equipped with terminal boxes where the cable connection is located. This design allows not to cut the cable if necessary to remove pumping equipment from the well. If such a device is not provided, the owner will be forced to cut off the cable.

- The universal head, painted black on the right side and made of aluminum, is often additionally equipped with a built-in electrical unit. The terminal block switches the wires, which saves on the power cable from the water intake point to the house.

- The electrical unit performs real-time diagnostics of the pump and supply line.

The tightness of the connection between the cover and the flange is ensured by the sealing ring.

Product Installation

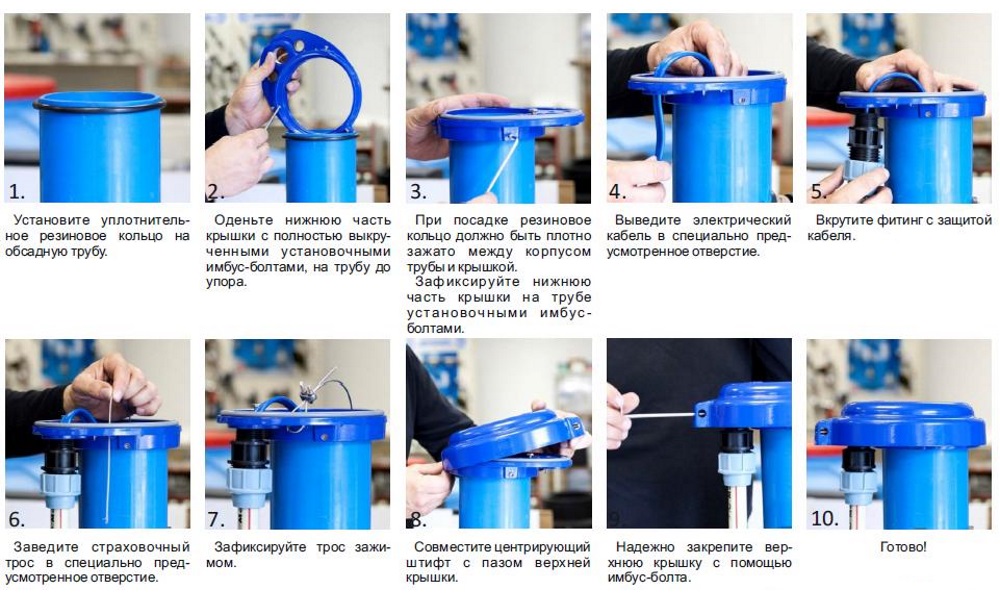

Regardless of the type of protective cover, the installation algorithm is the same everywhere. Do not neglect them, otherwise the device will not be able to perform its tasks properly.

- An o-ring is required on the casing. This will make it possible to tightly fix the equipment in the future.

- Proceed directly with the installation from the bottom of the cover. It is lowered all the way until it sits firmly on the rubber seal. The ring should be tightly sandwiched between the cover and the casing body.

- The lower part of the cover is fixed with the help of bolt bolts.

- Through the hole designed for cable entry, the electric wire of the water pump is drawn.

- The protective cable fitting is screwed in, and a cable is inserted into the hole.

- With the help of clamps, the cable is fixed at a certain distance.

- The upper part of the lid is equipped with a special groove, which is combined with a centered pin.

- The upper part of the cover is connected to the lower part with the help of bolt bolts.

Making a cap for a do-it-yourself water well

The protective part can be purchased ready-made in the store or made independently at home. A home-made design is many times cheaper, while any diameter can be adjusted.

To make the tip yourself, you will need the following consumables and working equipment:

- Fixing bolts with which it will be possible to ensure a reliable connection of parts.

- Sheets of cast iron, aluminum or steel no more than 10 mm thick (plastic can also be used).

- Dense rubber from which the rubber gasket-seal will be cut. It is installed between the head cover and the flange.

- Metal cutting equipment and welding machine.

If everything you need is prepared, you can begin to manufacture the head for the well. The technology is as follows:

- A metal flange is cut out. Its diameter should slightly exceed the diameter of the casing. It is rolled up and welded at the junction. The result is a kind of glass, which is welded to a part intended for the installation of fasteners.

- Cut out the lid. Its diameter should be the same with the diameter of the flange skirt. Due to this, it will be possible to ensure a reliable connection of all elements of the head.

- From the inside, one eye bolt is welded to the lid, which in the future will play the role of a guide cable holder.

- Two more eyebolts are welded from the outside. They are needed to raise the cover if necessary.

- The whole structure is securely bolted, first you need to lay the rubber ring between the cover and the flange.

The approximate price of a cap for a well is between 600-800 rubles. Do not underestimate the importance of the tip. A simple design effectively copes with a fairly wide range of tasks.