As the main purpose of the check valve on the water supply, the masters distinguish the organization of the flow direction in one direction. In addition, with the help of reliable fittings, it is possible to prevent leaks in the system, a decrease in pressure in the pipeline or an accidental shutdown of pumping equipment (for autonomous communication).

Definition and purpose

A non-return valve is a type of shutoff valve for a water supply system. Thanks to this device, the master organizes the direction of flow of the transported water and eliminates its reverse current. Application area:

- risers of cold and hot water in apartment buildings;

- individual water supply systems in the residential area (including autonomous private communication);

- submersible vibration pumps;

- autonomous water stations equipped with a pump;

- cold water inlet for storage boilers;

- device boiler equipment, etc.

The stop valves are mounted in accordance with the arrow on it.

Principle of operation

The non-return valve works thanks to the integrated shut-off mechanism. It is made either in the form of a ball or in the shape of a petal. The principle of operation of the reinforcement is as follows:

- Water moves in a given direction, increasing the pressure at the valve inlet.

- The locking mechanism opens and passes water forward.

- As soon as the fluid movement through the pipeline stops, the pressure in the network drops - it is equalized at the inlet and outlet of the valve. The locking mechanism closes, thereby preventing reverse current.

Additionally, the volume of water in the system is supported by a locking ball / lobe, not allowing it to open.

Types and device

Classification of shutoff water fittings occurs in several ways. At the place of installation of the check valve in the water supply system:

- Piping. Designed to prevent pressure drop in the system. If a non-return valve is not installed in the water supply, the water will drain down again when the tap is closed. Serious losses are generated on the network. The water meter in this case considers only the flow of fluid going forward.

- Bottom line. They are installed on a section of a vertical pipeline leading from a well / well to a pump.

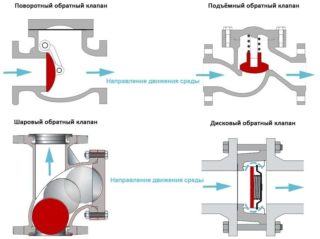

Depending on the design of the internal locking mechanism, these types of check valves are distinguished:

- Ball. It has a locking ball in its design, which is pressed against the device seat with a special return spring. More often, such a non-return valve is used on domestic water pipes and pipes of small diameter.

- Lifting. Equipped with a disk locking mechanism. It moves up / down depending on the change in pressure in the system. When changing the direction of fluid flow, the valve closes the valve clearance. The lifting mechanism can only be placed on a horizontal pipe with clean water.

- Turning. It has a locking mechanism in the form of a damper, which reclines at the moment of pressure change in the network. The return spring helps the sash to close when the water flow stops and not let it go backwards. The rotary check valve can be placed on pipes of large diameter and on water with impurities.

In order to avoid possible water hammer in a system with a lifting mechanism, it is important to strictly observe the “top” marking on the valve. It is also advisable to observe the maximum slope and additionally use damping water hammer elements.

According to the installation method, reverse water valves are:

- Flanged.Mounted on cast iron pipelines. Mounted by flanges.

- Wafer. In addition to flanges, special metal studs are used for fasteners.

- Coupling. Mounted on a threaded connection. Most often used on household piping.

According to the material of manufacture, non-return valves are cast iron (the most inexpensive, used on city highways); brass (reliable, corrosion resistant, household); stainless steel (the most expensive and high quality).

Check Valve Dimensions

Allocate such sizes of shutoff valves:

Allocate such sizes of shutoff valves:

- 1/2 inch - has a very low bandwidth. Used rarely.

- 1 inch is the most popular version of the device for a domestic water supply system.

- 1 ¼ - designed for large highways.

- 2 inches - placed on wells and in autonomous, suburban water supply systems.

- 3/4 - designed for central highways.

The valve must have the same diameter as the pipe on which it will be installed.

The size of the conditional passage of the reinforcement is from 10 to 400 mm.

How to choose fittings

Choosing a non-return valve, an experienced master pays attention to the following parameters:

- The size. If you buy a smaller stop valve and still install it using adapters, the reliability of the mechanism will be in doubt. In addition, the resistance to the moving flow will be increased.

- Destination For example, lift check valves need to be mounted in a strictly specified position, forming a rod stroke perpendicular to the ground.

- Material. On hot water pipelines it is better to use a steel or brass mechanism. Polymers interacting with high temperatures quickly fail.

- Docking Method. For domestic water supply, clutch valves are used more often to avoid additional adapters on the pipeline.

It is better to purchase valves in a specialized store. There, the buyer is given a check for the goods. Based on it, you can exchange the product or return it.

Mounting Features

A correctly selected check valve is only half the battle. Next, you need to correctly mount it. Otherwise, the device will fail many times faster. This will entail additional efforts and financial costs. When installing a check valve, you need to pay attention to such points:

- Arrow on the body. Its direction should look towards the water flow in the system both with horizontal and vertical installation of fittings on the input.

- The part must be placed immediately after the water meter, to where the branching of the water to different plumbing points begins. Thus, the meter will accurately determine the amount of water consumed per apartment / house.

- Clutch devices are installed by cutting the pipe in the desired area behind the water meter. A thread is cut into the ends of the tube. Then put on the check valve and tighten it with nuts from both ends.

A properly installed mechanism must not allow water to pass back. If this is observed, the valve is defective or the installation has failed.