To maintain a stable pressure in the water supply system, a hydraulic accumulator is installed. It is a sealed container separated by an elastic membrane. The tank accumulates liquid, which is distributed at the right time. What value of air pressure should be in the accumulators, the manufacturer establishes. When installing the system, you can calculate the optimal parameters and independently perform the adjustment.

Pressure accumulator value

Inside the hydraulic tank there are two media - air or gas and water filling the rubber membrane. The principle of operation of the device: when you turn on the pump, the fluid enters the expandable tank. Gas is compressed, its pressure increases. Air pressure pushes water from the membrane into the piping. When the indicator that the automation is set to is reached, the device turns off. Water consumption comes from the stock of the accumulator. A decrease in fluid volume leads to a drop in pressure and a restart of the pump. The hydraulic accumulator is controlled by a pressure switch.

The main function of pressure in the accumulator is to create optimal conditions for the operation of the pumping station. Air pressure excludes turning on and off the mechanism after each opening of the valve. Installing the drive in the water system solves other problems:

- Prevention of spasmodic changes in pressure in the pipeline (water hammer), causing damage to pipes and mixers.

- Extending the life of pumping equipment, preventing wear of parts and assemblies.

- Creating a supply of water inside the tank, which is used when a power outage.

The choice of tank volume depends on the power and type of pump. Units with a built-in frequency converter are characterized by smooth start-up. For them, a tank with a minimum capacity (24 l) is enough. The lack of mechanisms is high cost, they are rarely used in private households. A common option is low-cost borehole pumps, which give maximum power at startup. They quickly create high pressure in the pipes. It must be compensated by a membrane tank.

When operating surface pumps with a power of up to 1 kW, it is recommended to install a drive of 24-50 liters. For submersible units with a power of 1 kW, a hydraulic accumulator of 50-100 liters is required. Mechanisms with professional characteristics are equipped with tanks from 100 liters. The size of the storage tank is affected by the average consumption of water.

Types of accumulators

Capacities vary in size, purpose, performance. The design and functions of the tanks remain unchanged.

By appointment:

- for hot water (red color);

- for cold water (blue).

The difference between storage tanks in the material of which the membrane is made. In a container designed for drinking (cold) water, rubber that is safe for human health is used.

By execution:

- vertical models - used for limited space;

- the horizontal version is used in conjunction with an external pump mounted on the housing.

Each type of device is equipped with a special device for bleeding air. A valve is installed at the top of the vertical hydraulic tanks. Accumulated air is released through it, preventing the formation of plugs in the system.In tanks of horizontal type, a node of pipes and ball valves is provided. Drain is carried out in the sewerage. In tanks with a volume of less than 100 l, valves and drain units are not installed. Air is removed during preventative maintenance.

Drives are installed in heated rooms. Devices must be freely accessible for repairs and maintenance.

Optimal performance

The functioning of the water supply network and the resource of the drive depend on several factors:

The functioning of the water supply network and the resource of the drive depend on several factors:

- Correctness of the choice of the maximum and minimum pressure at which the automatic pump activation is triggered.

- Proper installation of the level of air pressure in the tank.

When performing an independent check and adjusting indicators, one should adhere to the recommendations of specialists. The basic rule is that the air pressure in the accumulation tank must be lower than the minimum pump start pressure. The difference between the indicators is 10-12%. Compliance with the recommendation allows you to save a small amount of water until the next turn on the unit. Example: if the pumping station starts automatically at 2 bar, the air pressure should be 2-0.2 = 1.8 bar.

The air pressure in the storage tank is independent of its volume. The average for tanks with a size of 24-150 liters is 1.5 bar, 200-500 liters - 2 bar. The initial factory air injection of 1.5 atmospheres in the conditions of small water consumption of a one-story building can be reduced to 1 atmosphere. The low pressure in the pipes reduces the wear of the system, but limits the use of plumbing fixtures. A reduction in pressure to less than 1 bar will result in excessive stretching of the rubber bulb. The membrane will come into contact with the metal casing. Contact will result in accelerated wear of the rubber.

Excessive air pressure (more than 1.5 bar) is also not desirable. It will take up most of the tank, reducing the amount of water collected. Also, there will be an increased load on pipes and nodes of the water supply system.

The pressure of water in the membrane is created by the pump. Its maximum permissible value is indicated by the manufacturer. A common indicator for household models is 10 bar. When the accumulator is connected to the system, fluid is supplied slowly to avoid damage to the membrane.

Pressure calculation

To calculate the optimal air pressure in the tank, there is a formula: P = (Hmax + 6) / 10, where

- P is the air pressure in the atmospheres;

- Hmax - the distance to the highest point of the home water supply network.

The top parsing point is the shower on the top floor of the building. The distance from it to the installation site of the pressure vessel is measured. The larger the gap, the higher the pressure required to raise the water. The use of numbers will add clarity to the calculation. For a building with a height of 2 floors, the Hmax value will be 7 m. The pressure will be P = (7 + 6) / 10 = 1.3 atmospheres. For a height of 10 m, a pressure of 1.8 atmospheres is required.

Before buying a hydraulic accumulator, the volume of the device is calculated. The calculations take into account:

- maximum water consumption;

- number of pump starts per hour;

- air pressure in the tank;

- lower and upper pressure limits for pump actuation;

- coefficient related to pump power.

After installing the membrane tank, you will need to set the minimum and maximum threshold for the automation (pressure switch). The volume of water coming from the hydraulic accumulator depends on the difference between the maximum and minimum indicators. Increasing the parameter increases the efficiency of the device, but leads to rapid wear of the membrane. For private homes, a difference of 1-1.5 bar is recommended.

The minimum pressure indicator in the membrane (Pmin) should be 10% higher than that of the air in the tank cavity. For stable operation of the system, the pressure drop should be 0.5 bar or more. This value is taken into account when calculating Pmin.The upper response (Pmax) is calculated based on the characteristics of the pump - the pressure value is divided by 10. The calculated value does not correspond to the real value due to changes in the declared unit parameters associated with wear. It is recommended to take the upper level indicator 30% less than the pressure characteristic.

Verification Methods

The air pumped into the tank at the factory gradually escapes through the rubber membrane and nipple. The dilution of the gas cavity leads to excessive stretching of the rubber bulb when filling it with liquid. Without resistance, the membrane wears out quickly and can burst. Measurements of air pressure are carried out by a manometer. The best option is a car measuring device.

The manufacturer's instructions indicate the number of checks for the device model. The average figure is 2 times a year. Before starting the parameter measurement procedure, all liquid must be drained from the tank. The pump is disconnected from the power supply system. At the time of measurement, the tank must be empty. Monitoring is required before connecting the device to the system. During storage, part of the air may leak from the tank. Working pressure is indicated in the product passport.

To carry out the test, unscrew the decorative cap that closes the nipple. The assembly is located at the top of the chassis. A pressure gauge is connected to the spool. The device should have a minimum error. Electronic and automotive devices are recommended. It is better not to use cheap plastic pressure gauges, they have a significant error of indicators. If the level is less than the factory settings, air is pumped using a compressor. The accumulator is left for a day for control. After the next measurement corresponding to the norm, the device is installed. Exceeding the optimum pressure is eliminated by venting.

The number of checks depends on the duration of use of the plumbing system. For summer cottages where communications are operated in the spring-summer period, indicators are monitored before the start of the season. A sign of reduced air pressure is the frequent on and off of the pump. For any deviations from the norm, an unscheduled check is carried out. A slight loss of air can be pumped up by a car pump.

How to properly adjust the pressure in the accumulator

Correct operation of the pumping station requires the competent adjustment of three main parameters:

- The pressure at which the pump starts.

- The shutdown level of a functioning unit.

- Air pressure in the membrane tank.

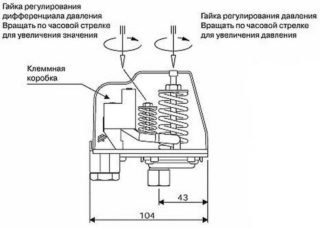

The first two parameters are regulated by a pressure switch. The device is installed on the inlet fitting of the accumulator. Its adjustment is carried out empirically, to reduce the error of the action are performed several times. The relay design includes two vertical springs. They are seated on a metal axis and secured with nuts. Details differ in size: a large spring regulates the inclusion of the pump, a small one is required to set the difference between the upper and lower pressure. The springs are connected to a membrane that closes and opens the electrical contacts.

Adjustment is made by turning the nut with a wrench. Clockwise rotation causes the spring to compress and increase the threshold for turning on the pump. Turning it counterclockwise weakens the part and reduces the response parameter. The adjustment procedure occurs according to a certain scheme:

- The air pressure in the tank is checked, if necessary, pumped by a compressor.

- The large spring nut rotates in the desired direction.

- The tap for water discharge opens. The pressure drops, at a certain moment the pump starts. Pressure value is noted on the manometer. If necessary, the procedure is repeated.

- The difference of indicators and the limit of shutdown is regulated by a small spring. It is sensitive to tuning, so the rotation is half or quarter turn.

- The indicator is determined with closed taps and the pump turned on. The pressure gauge will show the value at which the contacts open and the unit shuts down. If it is 3 atmospheres or higher, the spring should be loosened.

- Drain and restart the unit. The procedure is repeated until the necessary parameters are obtained.

The factory settings of the relay are taken as a basis. They are indicated in the device passport. The average pump start-up rate is 1.4-1.8 bar, shutdown is 2.5-3 bar.

Installation of a hydraulic accumulator in a water supply system allows you to maintain pressure in an autonomous network and to avoid water hammer. A functioning drive reduces the number of starts and stops of the pump, preventing wear on the mechanism. Timely checks and adjustments of the air pressure in the tank will ensure the operational state of the system for several years.