Ion exchange resins are compounds that do not dissolve at a high molecular level and are capable of producing a reaction when interacting with ionic elements of a solution. Ionites have a three-dimensional gel or macroporous structure. Resins are used to purify, soften and desalinate water.

Resin classification

Such compositions are divided into cation exchange, anion exchange, bipolar.

Cation exchange compounds can be weakly acidic and strongly acidic. The latter are able to exchange cations regardless of pH. The first work only with an indicator of at least 7.

Anion exchange compositions are strongly basic and weakly basic. The first anion exchangers have the property of exchanging anions in solutions at any pH, which weakly basic anion exchangers cannot. For them, the indicator should be from one to six. Anion exchangers of intermediate and mixed activity are also found.

Properties and principle of operation

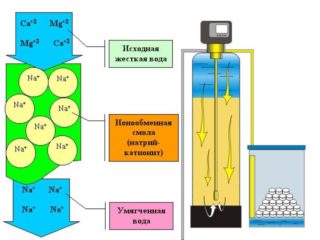

Ion exchange resins are insoluble polyelectrolytes. A multiply charged ion is motionless due to the high molecular weight. It is the basis of ion exchanger, is associated with small mobile elements with the opposite value, and, in turn, can exchange them in solution.

Ion exchange resins are insoluble polyelectrolytes. A multiply charged ion is motionless due to the high molecular weight. It is the basis of ion exchanger, is associated with small mobile elements with the opposite value, and, in turn, can exchange them in solution.

When filtering fluid passes through a resin filter, it is cleaned:

- from dangerous chemical impurities;

- from potassium and magnesium, forming scale;

- from salts of heavy metals, iron compounds.

The principle of operation of filtration devices with ion-exchange resin is aimed at cleaning and improving the quality of hard water. Resin polymer balls initially include “free” ions that are capable of trapping ionic particles of other substances.

Fragments of the ion exchange resin swell in the process of interaction with the water stream. The value of spherical polymers can reach 4 mm.

The liquid, giving away ions of heavy metals and harmful components, receives neutral compounds in return.

In addition to helium, there are macroporous ion exchangers. Their advantages are a slight change in volume, better adsorption, duration of metabolic processes, accelerated filtration.

Scope of application

Due to the softening and desalting effect, ion-exchange resins for the treatment of industrial water are used in the heat and power and chemical industries. In the hydrometallurgical industry, they are used to work with non-ferrous and rare metals. Ionites are also able to clean sewage ponds. Anionites are often used in aquarium water treatment - they contribute to the creation of comfortable living conditions for fish and plants.

In everyday life, ion-exchange filters have many useful properties:

- scale does not form on plumbing devices and heating units of household appliances, a boiler or a gas column;

- fragility of hair and dryness of the skin decreases, dandruff disappears;

- the consumption of detergent compositions is reduced three times;

- faucets and taps leave gray and rusty deposits.

If scale does not form on the heating element, this significantly reduces electricity consumption.

The domestic use of ion exchange resins is not dangerous, since these substances are not toxic. They do not have a tendency to self-ignition, do not explode. Filter elements with such resins are mounted in front of the boiler, boiler or flow-type water heater.

Criterias of choice

Ion exchange resins can be found in stores selling water treatment products, or on the World Wide Web.

When choosing, you need to pay attention to such characteristics:

- Humidity. The composition contains chemically bound moisture. If you get rid of it, this will lead to the destruction of the ion-exchange resin.

- The capacity of the ions. It is working, volumetric, weight. The last two indicators are standard, they are determined in the laboratory. Their values are spelled out in the accompanying documentation. Find out the volume of the working capacity does not work, because its performance is determined depending on the shape and depth of the filter layer of resin. The input characteristics of the liquid being cleaned are also important.

- Filtration rate and regeneration level, as well as the amount of trapped impurities.

For trouble-free cleaning and filter performance, it is recommended that the cartridges be replaced at least once for four to six months.

Features of packaging and storage

In accordance with GOST 20301-74, ion-exchange resins are packed in polyethylene bags. The maximum weight of one package can reach up to 50 kg. Also, these components are allowed to be packaged in cans or containers made of propylene.

The average cost of ion-exchange resin in Russia is 120–150 rubles per liter.

During transport or storage, the presence of resin cation exchangers near anion exchangers, any oxidizing substances or solvents is unacceptable.

Storage of products is allowed only in dry rooms with good ventilation and a temperature regime of at least two degrees of heat. Folding packages is allowed at a distance of more than a meter from appliances that heat the room. The shelf life of the resins is 12 months.

Ion exchange resin recovery

Filter elements with ion exchange resins for industrial or home water softening require systematic cartridge changes. It is more economical to regularly fill up the regeneration salt. Such measures are not labor-intensive, but their productivity is not so high. In addition, you can’t resuscitate the filter for a long time - for effective softening, you will need to completely replace the filler.

Just filling up the gravel cushion and filtering load is not difficult, but unloading the spent filler is not an easy task. Especially if the reservoir of the filtration device is made of fiberglass and is not equipped with a drain system. Having disconnected it from the water supply system, and having dismantled the control valve, serious efforts will be required to transfer the massive filter from the house to the street.

If this succeeds, they unload. To do this:

- Place the filter element on its side on a flat surface.

- To the introduction of the tube for lifting water with a hose clamp, attach a reinforced hose to supply water through it under a certain pressure.

- Rinse the loosened filler with a stream of water.

- After the container is completely empty, remove the water tube from the softener or filter element.

- After that, perform a secondary flushing of the tank and bring it back into the house.

There are organizations specializing in the maintenance of water treatment systems. Self-selection of a filter element for water is also problematic. When choosing expensive equipment, it is better to resort to the help of a specialist.

The best solution would be to contact the organization involved in the installation of filtering devices and providing a full range of services. This can be professional advice, analysis of water from a well or a well, assistance in choosing the right equipment, delivery and installation of the device, as well as after-sales service.