During the operation of main water pipelines, emergency situations occur. If you need to restore their work in a short time, special equipment is used that helps block the bursting areas, block cracks and places damaged by corrosion. Prices for repair clamps for water pipes are affordable. Spare parts help replace a damaged area without disconnecting the network. For installation there is no need to use welding machines. Only a suitable size screwdriver is needed to install them.

Types, device and technical specifications

The range of repair parts is great. There is a classification that helps you choose the right equipment. According to the material of manufacture, the clamps are divided into products:

The range of repair parts is great. There is a classification that helps you choose the right equipment. According to the material of manufacture, the clamps are divided into products:

- galvanized steel;

- from alloys without anti-corrosion coating;

- cast iron;

- from stainless steel.

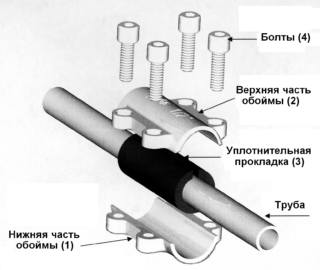

According to the type of construction, the clamp can be one-sided, two-sided, multi-component or fixing. The one-sided is U-shaped with a hole in the upper part. It is used for repairing pipes of small diameter (allowable size D / 50 mm), for threaded installation. Bilateral - a product consisting of two parts. They are interconnected with screws. Then the bond is further enhanced by staples. They provide a tight seal. Such products are selected taking into account the diameter of the pipe being repaired.

A multi-part clamp is used to repair a large diameter pipeline. It consists of several identical parts with a cellular structure. When installing, threaded pairs are used.

The mounting clamp is designed to mount the pipe to the surface. It is fixed with one screw, which is passed at the bottom of the product. First, a repair element is attached to the wall, then a pipe is inserted into it.

Criterias of choice

When buying clamps for repair work, it is necessary to take into account different parameters. Among them, experts identify general requirements.

- Do not use the product if its length is less than the outer diameter of the pipe.

- When repairing a pipeline with a diameter greater than 350 mm, it is important to use a bandage, the length of which is 150 mm longer than the damaged area.

- For large structures, repairmen recommend purchasing a patching product, the length of which is 200 mm longer than the length of the damaged area.

- To "treat" the polypropylene pipe, it is necessary to use clamps whose length exceeds one and a half times the length of the fistula or crack.

- If the clamp is used for joining two pipes, their ends should be at a distance of 10 mm from each other.

It is permitted to use clamps only if the area of the damaged area is not more than 60% of the clamp area. When a crack in a pipe is larger in size than 60% of the area of the bandage, it is better to use repair couplings to seal it.

It is necessary to take into account the technical operating conditions of the repaired object. For example, clamps cannot be installed where the pressure inside the water supply system exceeds 10 atmospheres. Patching a pipe in this case is useless. You can not install the clamps on the pipeline, inside which the carrier has a temperature exceeding +120 degrees. It is allowed to use the described repair equipment where the temperature of the carrier is constant and it fits in the range from -20 to +60 degrees.

Clamps can be mounted not only on pipelines inside which water is transported, but also on systems where inert gas or air is supplied through pipes.The crimp structure in this case should be a tape made of stainless steel. The thickness of the alloy must be at least 2 mm. If it is necessary to use a multi-part clamp, experts recommend choosing models made of high-carbon steel (M 20). Permissible is the use of cast iron clamps.

Another selection criterion is the nature of the damage. To eliminate tube fistulas, products with an elastic gasket are suitable. It is convenient to use a bandage with a key if there is no screwdriver or keys at hand. Power couplings are more suitable for repairing hoses and pump systems. For repairing pipelines with the maximum permissible atmospheric pressure, it is better to use clamps that use bolts with nuts instead of screws to fix the equipment.

Installation and mounting methods

The described cuffs can be used to repair vertically and horizontally located pipes. In curved sections, the use of such repair equipment is undesirable. The installation process is extremely simple. Installing the clamp on the water pipe is carried out in two stages:

The described cuffs can be used to repair vertically and horizontally located pipes. In curved sections, the use of such repair equipment is undesirable. The installation process is extremely simple. Installing the clamp on the water pipe is carried out in two stages:

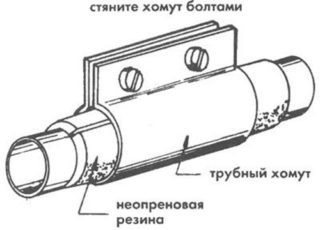

- The base of the bandage is put on the pipe in such a way that the lock that will fix it, stands on the opposite side of the damaged area.

- The nuts are tightened until the cuff used is fully adhered to the base body.

The quality of repair work depends on several criteria: on what material the clamp is made of, what strength it has. Of great importance is the adjoining area of the repair cuff. The greater the defect in the pipe, the greater should be the indicated indicator.

Advantages and disadvantages of repair clamps

The use of the described equipment has a number of positive aspects. It helps in repairing minor defects. It is possible to eliminate simple and complex accidents as quickly as possible and dispense with costly replacement of the damaged area.

Clamps are a multifunctional device. They are able to fulfill the role of the connection and the role of fastening the pipeline. Any person with minimal knowledge about installing a water supply system can supply a pipe clamp for repairing a water pipe. Installation takes place in a short time (in just a few minutes). Fixing is carried out by bolts and nuts. A quality product lasts a long time. Choosing it for the restoration of technical units, it is possible to extend their service life by another five years.

There is only one drawback: it is allowed to mount the clamp only on straight sections, from the outside of the highway. The maximum pipe size is 340 mm. For products with a larger diameter, the described device is not installed.

The price of all products is different. Its formation depends on what the described repair element is made of, what design it has, what system is used to fasten it to the defective area. Couplings that are simpler to manufacture are cheaper than multi-component elements. Another factor affecting pricing is the manufacturer and brand of the product.

British, German and American stainless steel pipe clamps with anti-corrosion coating and swivel clamp cost $ 0.30 - $ 5.00. Domestic products are cheaper.