To make an extension to connect an additional unit of sanitary equipment or to form a new circuit, you will need a clamp for inserting into the water supply network. In order for the connection to be strong, it is important to choose the shaped element correctly and correctly install it.

Scope of the part

Clamps are used in those situations when it is necessary to crash into the water supply. This is required when carrying out repair work in the apartment, changing the location or replacing communications, in cases where it is not possible to stop the incoming water flow or not.

Clamps are used in those situations when it is necessary to crash into the water supply. This is required when carrying out repair work in the apartment, changing the location or replacing communications, in cases where it is not possible to stop the incoming water flow or not.

The insertion will be required in such cases:

- connecting a new water intake point, for example, a washing machine or dishwasher;

- acquisition and launch of new water consumers, for example, a jacuzzi;

- replacement of water pipes if they have become unusable or with the aim of carrying out work to modernize the water supply system.

These details will be required during the redevelopment of housing with a new location of sinks, bathtubs, the transfer of faucets, the creation of combined or separate bathrooms - bathrooms and toilets.

The insertion into public water supply pipelines of the main type also takes place with the use of clamps. But these actions cannot be carried out without appropriate permission. The implementation of an unauthorized tie-in entails bringing the owner to material and administrative liability.

Connecting to a public water main of large type, bypassing metering devices, is strictly prohibited.

Types of clamps and features of choice

The clip is used to connect a non-pressurized main water line to the pipeline. The device consists of two parts, one of which is equipped with an outlet with an internal thread. The installation of the sleeve coupling for insertion into the water supply system is carried out by means of a bolted connection. Such an accessory is made of HDPE or metal.

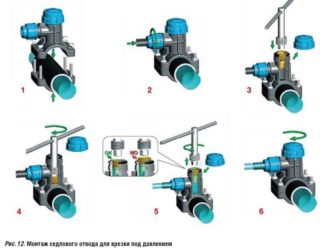

The drilling clamp for tapping into a water pipe under pressure is a prefabricated module equipped with special nozzles and rotary connectors. It is mounted on polymer, cast-iron and steel water supply lines.

An electrowelded seat for a water pipe is used exclusively for tapping into plastic systems. The device contains a cutter for drilling holes in the pipes of the polymer, mounted in the locking element with a tap, and a heating spiral.

Simple saddle clamps are used for tapping into asbestos-cement, polymer and metal lines. The device differs from the clip holder in that it constructively consists of the main part - the “saddle”, which is fixed to the pipe with the help of an elastic clamping bracket. The tightness of the connecting element to the water pipe is ensured by special rubber seals, guaranteeing the tightness of such a connection. Most of these devices are made of metal.

Saddle clamps are universal. They can be used to connect to the main pipeline, both under pressure and without it.

Insertion Methods

The material of the water supply network plays an important role during the insertion. It determines the technological process in accordance with which the work is carried out, and the selection of a suitable clamp. But in any case, the installation work should be at the least or absent pressure of the water flow.

The material of the water supply network plays an important role during the insertion. It determines the technological process in accordance with which the work is carried out, and the selection of a suitable clamp. But in any case, the installation work should be at the least or absent pressure of the water flow.

Clamp installation on plastic pipes

In the house network, you can stop the flow of fluid if necessary, simply by shutting off the main tap. Therefore, in order to perform an insert in this case, only a regular tee is required. The process itself is carried out in this way:

- They block the main locking element, and after that - the tap located at the very bottom of the system to drain the liquid from the water supply.

- The trunk is divided into the required section using angle grinders or pipe cutters by cutting a section equal in length to the inserted fitting. Before performing such an operation, it will be necessary to install a suitable container to collect the water remaining in the pipeline under the site of the future cut.

- A tee is cut into a plastic water pipe in the same way as a standard coupling, the joints are welded using a special soldering iron for propylene pipes.

- A shut-off valve is installed in the branch of the tee, which makes it possible to block a new water line. After this, the water supply system can be used, you just need to open the main locking element.

Installation of a new branch can be performed when the pipeline is under pressure, since a separate stop valve is installed on the branch of the tee.

The best option for pipes made of polymer will be a collapsible collar with a built-in heating coil. During installation, it is disassembled, installed in place of the tie-ins and soldered to the pipe by means of a welding machine. Thanks to this connection method, a tight and high-strength connection is obtained.

Works on metal plumbing

For metal pipelines, it is advisable to use a saddle clamp. The beginning of the installation is similar to installation on pipelines made of polymers, but the part itself is embedded as follows:

For metal pipelines, it is advisable to use a saddle clamp. The beginning of the installation is similar to installation on pipelines made of polymers, but the part itself is embedded as follows:

- Fix the clamp on the surface of the pipe.

- Drill a hole.

- Install the plug in the form of a screw intended for this.

The use of a clamp, complete with a valve, is also available. Here the order is the same: a hole is made, the drill is removed and the valve is shut off.

On external water supply networks, excavation work will be required. You will need to dig a foundation pit measuring 150 x 150 centimeters and a depth of 50 cm below the main line. You can start excavation using an excavator until a tape of metal or polymer appears, which is laid over the highway at a height of 30-50 cm. Further work is carried out exclusively with shovels. If a well is already mounted at the tie-in point, these steps will not be required.

The final phase is the diversion of the water supply branch from the main pipe. A new water line starts from the stop valves of the saddle, and ends on the water meter.

Features of insertion in a pig-iron pipeline

To drill a hole, you need a carbide crown. In the process, it quickly fails, it is better that three or four spare parts are at hand.

When working with cast iron, the following nuances must be taken into account:

- The fragility of the material. Pressure on him should be minimized.

- Mandatory removal of anti-corrosion coating. It is applied to all pipes.

- Inadmissibility of overheating of the crown.

Drilling must be carried out by setting the lowest revolutions of the working tool.

With a competent approach to the selection of the clamp and its correct application, it is possible to carry out independent installation of the water supply using a simple and affordable tool.