For urban housing, the uninterrupted supply of clean water is such a natural daily process that people do not even think about it. But in a country house or a suburban area, this may well become a problem. After all, in your own country house there are no utilities that could take care of a constant water supply. Therefore, the owners of the sites have to deal with the installation of a water supply system on their own, and one of the most effective methods is to drill wells under pressure.

Drilling Preparation

Do-it-yourself water boring of wells is not an easy task, therefore, it is unlikely that specialists will be able to do without it at all stages of drilling.

The owner of the site, who wants to carry out all the work himself, must acquire professional equipment, as it is necessary in a complex technological process. No improvised means will replace it.

First of all, you need to find a small-sized drilling rig (MBU). You can get it in two ways: buy or rent from a specialized organization. This device is expensive, so it’s best to contact a drilling company.

MBU is a design with dimensions of approximately 3 m in height and 1 m in diameter. Its components:

- tip for drilling;

- frame for fastening;

- a winch for raising and lowering the drill;

- rotary engine;

- water pump;

- swivel;

- a hand drill for passing soil, may be exploratory or lobed;

- drill strings forming a string;

- drill string string;

- system control unit;

- water hose.

In the process of water drilling, you will need to continuously supply the installation with electricity, so prepare a current converter. To pump the drilling fluid, you need a motor pump on gasoline.

Usually, during operation, a large mechanical load is created on the parts driven by the movement, so it is worth choosing the most powerful power source. Also need a system for filtering the drilling fluid and manual clamp.

Terrain Information Collection

When the required parts and equipment have been prepared, you can move on to planning a future process. Find out at what depth below the site is the aquifer closest to the surface. Maps of groundwater occur in land authorities. Be sure to contact them for information on the geodetic features of the area in order to know the exact number of casing pipes.

When the required parts and equipment have been prepared, you can move on to planning a future process. Find out at what depth below the site is the aquifer closest to the surface. Maps of groundwater occur in land authorities. Be sure to contact them for information on the geodetic features of the area in order to know the exact number of casing pipes.

Find out more about the ecology of the area. You need to make sure that there are no cemeteries, burials of animal corpses or other wastes nearby, including chemical emissions. The presence of any toxic source in the immediate vicinity may render the water unsuitable for human consumption. Then it makes sense to use the well to obtain only process water.

Site preparation

In the process of hydraulic drilling, a lot of water is involved - from 10 to 20 cubic meters. m on average. Make sure that it is close enough to where the well is drilled in advance. It is better to install several large-capacity containers made of metal or plastic by running hoses to them. If containers of a suitable size are not available, dig a hole, tightly tamp its walls and cover the entire surface with clay, after which water can be poured into it.

Install the drilling tool directly above where the well should be.An important point: MBU must be fixed strictly vertically, without the slightest deviation. Assume inaccuracy - you cannot install casing pipes. The assembly procedure itself is simple, takes 40 - 60 minutes with an unprepared person.

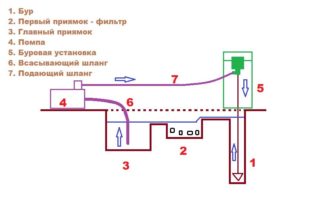

At a distance of 1–2 m from the MBU, 2 recesses are made under the solution for drilling wells with flushing. The filtration pit should be closer to the MBU, at a distance of approximately 1 meter and a volume of 0.5 cubic meters. m. A little further, you need to dig a larger main pit. They are connected by a direct trench so that drilling fluid can flow from one to another.

Behind a large pit, you need to put a pump to power the MBU. Two hoses emerge from it, one of which must be lowered into a large pit with drilling fluid, and the second should be connected to the swivel, which feeds the solution into the bailer for drilling.

Drilling technology

If you have to drill in sandy, loose soil, you will need a lot of water. Sand has the ability to quickly absorb large volumes of liquid. To minimize costs, the drilling fluid must be tight. To do this, mix water with clay in a pit. This principle will allow the solution to fill cracks and cracks when it enters the bailer, strengthening the walls of the hole.

When drilling wells with water under pressure, the technology assumes that the fluid is supplied to the choke by pumping from the tank with hoses. It is necessary to go deep into the soil until you reach the aquifer. The average depth that you need to dig MBU is 50 m.

To avoid collapse of the soil, it is necessary to install casing pipes after the reverse extraction of the drill rod. Do-it-yourself hydro-drilling is best done under a 125 mm pipe, as this is the most common diameter and is easier to find. The casing material is plastic or metal. The first is preferable, as it will last longer, easier to install and cheaper.

To keep the water clean, it is advisable to install a filter. Drill holes in one of the ends of the casing, wrap it with a geotextile or filter mesh, and then lower it down. When drilling wells for water, after completion of the process, it is necessary to clean the well from the solution. Put the cap with the hose on the edge of the pipe, and then supply clean water under pressure. After some time, no sewage will remain in the depths. It is only necessary to strew the bottom with gravel.

Pros and Cons of Do-It-Yourself Hydro Drilling

The advantage of hydro-drilling using MBU:

- No need to use expensive and heavy equipment that can ruin the landscape.

- The owner does not have to involve specialists in the work.

- To deliver MBU to your drilling site, you need a minimum of effort and time. The installation can be lifted and carried by one person.

- The dimensions of the installation allow manual drilling of wells with flushing even in rooms with ceilings of at least 3.5–4 m.

- The complete process of drilling the chute and installing the pipes takes 2 to 3 days.

Hydro-drilling with MBU is not suitable in places where the soil consists of dense and solid soils, if there are stones and gravel in the layers of the earth. In a similar situation, water drilling is not effective. It will not help if the groundwater laying layer is deeper than 60–70 m. Therefore, when choosing a drilling method, study the geodetic maps.