Drainage pumps are designed for pumping and transporting clean water and wastewater. The products of the famous Danish company Grundfos (Grundfos) are highly appreciated. Despite the fact that the equipment belongs to the category of expensive, in the Russian market it is in great demand. This is due to high quality, performance and power.

Grundfos drainage pump specifications

All equipment of the Danish company is made of high quality steel, which guarantees durability and a high degree of reliability. After production, each pump is tested, which allows you to check its performance. The case is tight, its surface is coated with a special paint, which additionally provides protection against corrosion.

Grundfos drainage pumps are characterized as follows:

- duration of operation;

- high level of wear resistance;

- compact sizes;

- the presence of a float switch.

During the manufacture of the pump, the rotor cavity is filled with environmentally friendly liquid, which increases the durability and safety of the user.

The lineup

Grundfos drainage pumps have a wide range. This allows you to choose the most suitable installation for specific purposes.

Grundfos drainage pumps have a wide range. This allows you to choose the most suitable installation for specific purposes.

Key models on the market:

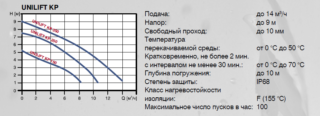

- Grundfos Unilift KP 150 a1 - designed for pumping clean and contaminated water, equipped with a wet rotor, which guarantees wear resistance. All equipment parts are made of stainless steel. An added benefit is that there is no need for maintenance.

- Grundfos unilift kp 250 a1

- Grundfos Unilift KP 350 a1 - designed for pumping clean water. It has compact dimensions, weight is 7.9 kg. This feature allows you to install it in narrow wells. Equipped with a built-in float switch.

- Grundfos Unilift CC 5 a1 - pumps clean and contaminated water, the size of solid particles should not exceed 10 mm. Equipped with universal pressure pipe connection, there is a cooling casing and a float switch.

Before buying, it is important to calculate the power of the equipment that will cope with the tasks.

Criterias of choice

When purchasing drainage submersible or surface pumps, they pay attention to important criteria:

- The size of the solid particles that the unit is able to pass through itself. It is better to study the maximum permissible parameters, it will depend on where to use the equipment.

- Specifications: operating temperature, maximum pressure, the presence of a float, power and performance.

- Maximum permissible immersion depth.

- Installation methods - horizontal or vertical position.

There is no need to buy the most expensive and powerful models. If the drain pump runs idle, it will fail more quickly.

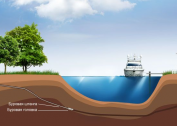

Installation Features

Pre-select a suitable place for installation. Main stages:

Pre-select a suitable place for installation. Main stages:

- Check for all necessary parts and read the attached instructions for use.

- Install the equipment in a vertical or horizontal position, as required by the instructions, and connect the line to the discharge pipe.

- Connect the equipment to the power supply and take measurements of the flow.

- Turn off the power and replace the phase, repeat the previous step.

- Compare indicators and choose the right one.

Installation is carried out carefully in accordance with the instructions.If the installation is performed incorrectly, the equipment may not work, quickly fail, or its performance will be reduced.

Advantages and disadvantages

Key advantages of Grundfos drainage pumping stations include the following technical characteristics:

- High build quality and materials used ensures the operation of the device for many years.

- Equipped with a float switch that controls the water level.

- The ability to manage not only stationary but also autonomously.

- Equipped with an integrated thermal protection system.

Of the shortcomings most often emit a high cost and the need for a constant connection to the power supply during operation.

The price of a drainage pump for dirty water Grundfos, as a rule, is 1.5 times higher than that of analogues. The initial cost is 2,000 rubles. It is better to purchase equipment from official representatives or in specialized large stores.