If there is even a small personal plot, few can refuse the temptation to install a barbecue, barbecue or grill in the yard. Nothing beats the aroma of open-fried meat and aromatic, juicy vegetables. Barbecue is becoming a regular event for every weekend and holiday. And when it is installed in a gazebo or under a canopy, even bad weather will not be able to prevent the preparation of barbecue and steaks in the open air. Barbecue can be installed indoors, which is very convenient for those who are used to cooking exclusively in the cozy atmosphere of their own kitchen.

But for a barbecue in the gazebo or room, you should definitely build an exhaust umbrella.

Why do you need a hood over the barbecue

An extractor hood, or an exhaust hood, has two main functions:

An extractor hood, or an exhaust hood, has two main functions:

- smoke removal from the barbecue;

- traction improvement.

In the process of burning wood, a large amount of smoke spreads over the entire yard, this causes considerable discomfort. But the hood eliminates this problem by removing all the smoke to a height of several meters from the ground.

In addition, an exhaust hood improves traction, as a result of which firewood burns out faster, and the temperature of the coals rises, which ensures quick and high-quality preparation of the product.

In addition, if the grill or barbecue is located outdoors, the umbrella protects it from direct moisture during rain. Such designs can be done with your own hands.

What are barbecue hoods

There is nothing difficult in building an exhaust hood with your own hands. But first you need to decide what it can be, and which option to choose.

The type of hood depends on the material from which it is made. It could be:

- metal;

- brick.

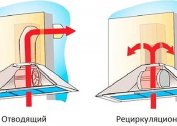

The design of both types of hoods has common elements. This is the umbrella itself, or the dome, and the pipe with which it connects. The dome is designed to collect smoke, and the pipe removes its top. The hood has good aerodynamics, because the smoke is taken away quite actively.

Important! The device only works if the bonfire has flared up well. At the stage when the fire is just flaring up, the smoke has almost the same density as the air, so an exhaust hood is useless to exhaust it.

How to make a smoke collector from metal do it yourself

A metal hood can have a round, oval, square or rectangular cross section. But the last two types of metal hoods with your own hands are the easiest to do, since making a dome-shaped umbrella will require certain skills and a lot of time.

It is desirable that the size of the smoke box slightly exceed the parameters of a barbecue or barbecue. Then its aerodynamic properties will be optimal for fast smoke exhaust. In this case, we will consider a structure with a diameter of about 1.5 meters. As a material for its manufacture, you can take sheet steel with a thickness of 1.5-2 mm. This is the most economical option. But if you need a more durable and beautiful design, you can take copper sheets.

From the tools you will need:

- Bulgarian;

- hammer;

- riveting tools;

- welding machine.

Metal hoods for barbecues require some skills in riveting and welding.

It is necessary to take care of the means of fastening the structure over the barbecue. It can be metal or brick racks on which the smoke collector will be held. In some cases, it is hung on chains from the ceiling of the gazebo.

Sheets of metal are cut so that the umbrella has a pyramidal shape.In the center there will be a hole, the sides of which should be at least 30 cm. Otherwise, a do-it-yourself device will not have sufficient aerodynamics.

The pipe is also made of metal sheets. It should have a height of 2-3 m.

Important! Asbestos pipes for hoods will not work. Although they have good properties, when heated they release harmful substances into the air.

The pipe must be firmly connected to the dome. The possibility of any gaps and cracks should be excluded, otherwise the hood above the barbecue will not have the desired effect. A metal pipe is best reinforced at the top. As a fastening element, brickwork or a metal frame can act.

Metal hoods for barbecue facilities have one drawback: they rust. So - the dirt and soot that settles on its walls will crumble on the brazier along with pieces of rust. Therefore, the metal surface must be constantly looked after, cleaning the soot layer from it.

Do-it-yourself hood over a barbecue made of brick

As already noted earlier, such a hood, as a rule, is designed over brick grills. If not - in any case, the basis of the entire structure is the walls in its lower part. And already in this niche it will be possible to install a metal barbecue.

Unlike do-it-yourself metal hoods, such structures are more durable and require virtually no cleaning. For its construction, the following tools will be required:

- Master OK;

- level;

- plumb line;

- pickaxe;

- Bulgarian.

Brick is better to take heat-resistant, so the design will stand as long as possible. A cement mortar will serve as a bonding material. Mixing proportions should correspond to the brand of cement. That is, if cement is grade 4, then its ratio to sand should be 1x4. Clay-sand mortar can also be used, but it will not be so durable.

In addition, 4 pieces of a metal corner will be required. Their length should be equal to the width of the walls of the barbecue. That is, if the barbecue has parameters 1X1.5 meters, we take 2 segments per meter, and two - one and a half meters. They should serve to support the hood. To do this, corners are first laid out on the walls of the barbecue, and only on top of them begins the laying of the hood.

In the case of a do-it-yourself brick hood, its dome should also have a pyramidal shape, as shown in the figure. Bricks of the first row are laid perpendicular to the wall, the second - in parallel. Above the masonry should narrow. The average number of rows should be 10. The width of the opening of the last row should be the same as the width of the chimney. It, as in the case of a metal hood, must have a height of at least two meters.