A cooker hood in the kitchen is a type of household appliance that eliminates unpleasant odors there, removes combustion products, fat and other particles from the air.

Often during the repair and redevelopment of the kitchen, the old hood is no longer suitable for its size or appearance. In this case, a home-made hood can help, which everyone can do.

What you need to know before work

Before you start developing a home-made cooker hood, you need to understand exactly how such a device functions, look at the network photos of finished models in order to choose the best option for yourself.

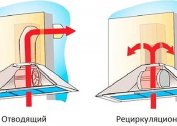

Not everyone knows that there are such types of devices that they do not just exhaust the exhaust air, but process it with special filters, releasing it back in purified form. Some models simply remove the air mixture from the kitchen through the ventilation system to which they are connected.

Therefore, the first thing to do before you develop hoods with your own hands is to make sure that the ventilation system in the house is working properly.

If ventilation is contaminated, traction will be reduced or even completely absent. As a result of this, the hood will not be able to perform its functions. Therefore, before starting all work, it is important to clean the air outlet system from the kitchen.

When plastic window constructions of high tightness are used in the kitchen, special ventilation valves should be installed on them, otherwise the operation of the hood will be of low efficiency.

A cooker hood with your own hands can be one of two varieties:

- active;

- passive.

Passive models remove the air mixture from the room only due to the upward draft, since they do not have any fans or electric motors. As a result, a hood made by itself of this kind can only work if the ventilation is in excellent condition.

Active hoods function thanks to an installed electric motor. Such models are highly efficient, but consume a lot of electricity.

Necessary materials and tools used

The next stage of the process, the result of which will be a hood for the kitchen with your own hands, is the preparation or purchase of all the required tools along with the materials. Among them:

- sheets of drywall, characterized by increased resistance to moisture;

- galvanized surface profiles;

- perforated corner;

- corrugated pipe;

- fasteners;

- insulation material on the corrugation;

- paint and putty, putty knife and brushes;

- puncher and screwdriver;

- overlays for corners.

Work sequence

After preparing all the required materials along with the tools, you can begin to perform the necessary work. Their first stage is the marking of the future device and its duct on the walls of the room. The easiest option would be the case when the ventilation hole is located directly above the hob. If it is somewhere to the side, it is also necessary to develop a box for decorating corrugations.

In the case of finishing the kitchen ceiling with drywall, the duct can be partially decorated with it.

The next step is to make a frame to accommodate the duct using metal galvanized profiles. Mount them where in the future the duct will pass, using an anchor.If the pipe is not straight, the profile will need to be installed with bends in the required places. The initial profile - the starting one - is set down in several parts, fixing them with self-tapping screws.

The next stage is the end of the arrangement of the drywall box. To do this, a second panel is installed on the finished parts. Upon completion of the development of the lower part, transverse slats are installed on top of it, later they will be sheathed with sheets of drywall.

At the fourth stage, you need to make the body of the future hood. Above the stove, the lower part of the exhaust device made of a profile is mounted on the wall. The task will be greatly facilitated when a niche is provided for the device. If it is not there, then the lower side of the hood to the box should also be attached on the sides. The main components of the hood are made from the profile, attaching them to the bottom. To give the structure greater rigidity, it can be strengthened with jumpers, which are also made from the profile.

Next - a connection to the ventilation system made duct. In this case, a corrugated pipe is used.

In order to prevent noise during operation of the hood, the pipe must be wrapped with high-quality soundproofing material.

The last step is to finish the device. To do this, the hood housing and duct duct are sheathed with sheets of drywall. Next, a putty layer is applied to it, which will hide the seams between the sheets and fasteners. After this, it remains only to paint the hood and the box, but instead they can be decorated.

This kind of design is suitable for both a passive and an active exhaust device. In the second case, an electric motor connected to a grounded power outlet must also be installed inside the device case. It will create strong traction that quickly removes exhaust air from the kitchen.

Features of the development of the frame

To make the appearance of the finished device attractive, you will need to perform such work.

Assemble the main body of the device by installing a grill on its lower part and, if necessary, an electric motor. If at the initial stages of work the design does not look very attractive - do not worry - the lining will qualitatively hide any irregularities.

Next, the frame is attached to the base, each one chooses its shape independently, depending on their own preferences. The main thing is that the duct should be placed inside. In this case, you can view ready-made ideas on a photo from the network or do it yourself.

Finishing details are cut from the selected material, with which the frame is glued. After the glue dries, the surface of the material is ground, a layer of putty is applied to it. After drying, it remains only to paint the finished hood, made by yourself, in the desired color.

Having done everything right, you will make a high-quality and functional range hood with your own hands, which will not only do a great job of fulfilling your duties, but also have an attractive appearance.

Thus, the process of developing a hood with your own hands does not mean anything complicated, so everyone can do it independently. As a result of this, a functional exhaust device will be obtained, which will differ in a completely original appearance.