Every housewife wants to equip her kitchen with the latest technology. Naturally, an extract to the kitchen with an air duct will be an indispensable component, ensuring the timely outflow of smells of cooked food.

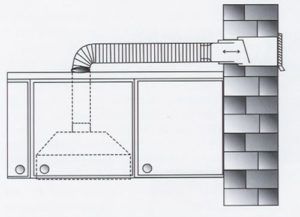

Cooker hoods consist of several structural elements. One of them is an air duct, the main function of which is to ensure the removal of air from the kitchen area. This is a special channel or pipe that delivers air from the intake exhaust device to the place of its output (for example, a ventilation shaft).

It is safe to say that without an air duct the entire ventilation system will not be able to function. However, devices that do not require ductwork have already appeared on the modern market. The air is cleaned directly in the hood using special carbon filters. This system is not very popular yet due to the need for frequent replacement of cleaning cartridges.

Differences between a kitchen exhaust system from ventilation

For residential premises, special sanitary standards have been established that determine the air exchange in the room. To fulfill these requirements, ventilation is installed in all apartments, capable of circulating air. However, for the localization of strong odors, burning and smoke, this system is unsuitable, since it works due to natural air exchange.

It is the presence of a kitchen hood that provides local intensive air exhaust. It is installed in places of increased accumulation of unpleasant odors.

Types of ducts for cooker hoods

There are several types of exhaust duct classification.

They are divided into:

- in form;

- according to the material from which they are made;

- by configuration.

When choosing a duct in the kitchen, it is necessary to take into account the entire set of parameters of this device.

Duct shape

According to the shape of the section, they are divided into the following types:

- rectangular. Such ducts are conveniently located behind the cabinets. On sale, they exist in the form of separate sections and adapters between them. This allows you to lay any trajectory from the exhaust device to the ventilation shaft. Suitable for kitchens with any ceiling height. They have a very aesthetic appearance. However, they have less performance than ducts of a different shape;

- round. Not suitable for kitchens with low ceilings, as they are very bulky. If the outlet is rectangular, then special adapters are required from rectangular to round;

- oval. They have the pros and cons of round ducts.

One of the varieties of rectangular ducts are flat designs. They are compact and easy to hide from the eyes. Available in three standard sizes:

- 110x55 mm. They are used for hoods with a capacity of not more than 300 m3 / h;

- 120x60 mm. Such air ducts are capable of passing through a larger volume of air, but not more than 350 m3 / h;

- 206x60 mm. The largest air ducts. They are installed to high-performance hoods when a high degree of purification of air from odors is required.

Duct material

For the manufacture of ducts in our time, it is customary to use the following materials.

Plastic (polyethylene, PVC and fiberglass)

The most popular material. Usually available in round or rectangular section.

And if rectangular ones look more beautiful, then ease of installation is a distinctive feature of round systems (usually they do not require special adapters to connect to the hood and ventilation grille).

The advantages of plastic ducts:

- smooth inner surface prevents the accumulation of dirt and grease inside the system;

- plastic pipes are not able to rust;

- light weight;

- ease of assembly. A wide variety of parts allows you to collect air ducts of any configuration and length;

- when working, there is no strong vibration and noise;

- low price.

Minuses:

- installation requires a variety of adapters and fittings;

- unstable to temperature rise. At high temperatures, they can release toxic compounds into the kitchen space.

Aluminum

Quite popular material. Corrugated pipes for air ducts are made of it. Its advantages include:

- ease of installation. Universal material for almost all cases;

- tolerates heat well;

- low price.

Disadvantages:

- not aesthetic appearance. To give presentability, a pipe of this type is hidden in a special box or laid inside the cabinet;

- mechanically unstable material, unstable to external influences and deformations;

- since aluminum conducts heat well, condensation may accumulate in the room where ducts of this material are installed.

Steel

Made of galvanized or stainless steel. But in home use in the kitchen, it was precisely galvanized models that found themselves. However, this type of air ducts is gradually becoming obsolete and is becoming less and less popular every year.

The advantages of ducts from this material include:

- smooth surface. The air flow rate does not decrease when passing through pipes of this type. They do not get stuck soot, dust and other pollution;

- easily withstand elevated temperatures, without any consequences for themselves and the environment;

- belong to the budget price category.

Disadvantages:

- Compared with the same plastic pipes, they have significant weight. Accordingly, additional fasteners are required when mounting on a wall;

- for sealing channels require additional mixtures or compositions;

- if it is required to assemble an air duct of complex shape, there may be a need to cut metal pipes;

- during operation they emit a sufficiently loud sound.

Duct Configurations

In this classification, duct pipes are divided into:

- flexible. These include corrugated channels, most often made of aluminum, but now models made of plastic have appeared. They can be placed at any angle. The ability to stretch or compress is an added plus. However, it is important to consider that a poorly stretched duct strongly interferes with the free movement of air, which greatly reduces system performance. Another disadvantage is that the corrugated box is not recommended to be made more than three meters long. Since each additional meter reduces productivity by 5-10%;

- tough. They are made of all three materials. Convenience in assembly and a smooth inner surface that prevents the accumulation of dirt are the main advantages. The price is slightly higher than that of flexible ducts, but ease of use compensates for this drawback.

Basic duct installation rules

Before starting the assembly of the duct, it is first necessary to determine its size. For optimal selection of the box, it is necessary that the following requirements are met:

- the size of the duct section must coincide with the exhaust outlet. A smaller pipe diameter will lead to excessive noise during the operation of the system and cause motor overload;

- if the outlet is different in shape from the shape of the cross-section of the duct, you must purchase a special adapter.

Installation Nuances

When installing the duct for the hood, the following points must be taken into account:

- The number of turns of the duct should be made as small as possible, since each bend reduces the efficiency of the exhaust system by 10%. Installation of no more than three elbows is recommended.

- Since the duct should be cleaned periodically, it is recommended to make it collapsible.

- When mounting a corrugated aluminum box, it is allowed to mount it to the hood with ordinary clamps.

- Do not mount the duct to the ventilation grille of the kitchen. With a tight fit of the box, while the ventilation system is not working, the natural air circulation is disturbed. In order to avoid this, installation of a special ventilation grille with holes and an integrated non-return valve is required.

- Using channels of different sizes is undesirable. This will require the use of special adapters, which greatly reduces the overall system performance.

- The most aesthetic appearance has a flat rectangular box.

Ways to hide the duct

For a more presentable type of kitchen, it is recommended to mask the channel system. The following methods are used for this:

- cleaned by a suspended ceiling. With its presence, all horizontal pipes are easily cleaned there. For vertical sections, special casings are made, covered with the same material as the ceiling;

- decorative box. There are many modifications of such a casing, differing in shape, color and method of execution. It is even allowed to integrate spotlights into it;

- while buying furniture, laying the duct is possible inside the cabinets or on their "cover";

- self-made production of gypsum board boxes is also possible. Further, in accordance with the design of the kitchen itself, the design is either painted in a certain color or glued with wallpaper.

Currently, a huge number of duct models for creating a kitchen exhaust system are presented on the market. And the question of choosing one type or another is determined not only by its design characteristics, but also by personal preference, ease of installation, and appearance. And the correct installation of the selected system will provide a good outflow of air in the desired area and save the kitchen from unpleasant odors.