One of the most important elements of the production process is to ensure comfortable working conditions. The condition and composition of air masses in any industry often requires adjustment due to dust, vapors and gases, excessive humidity, elevated temperatures or toxic impurities. Depending on the characteristics of the technological process, these factors affect not only the health of workers, but also the tightness of the equipment.

Acceptable temperature conditions, comfortable humidity and the removal of exhaust air masses contaminated with impurities are provided by an exhaust ventilation system. It should not be confused with the supply, which is designed to pump fresh air into the premises, although both of them carry out their functions using special equipment - fans or ejectors.

Extraction system using radial or centrifugal fans has been widely used in industry.

Exhaust systems using radial fans

Efficient and simple devices enjoy well-deserved popularity in the domestic environment. A snail hood, as such fans are called in a different way, quickly copes with eliminating odors, excessive humidity, lowering the temperature in the kitchen, bathroom, garage, basement or cellars. Such systems are used, for example, in boiler houses or apartment buildings.

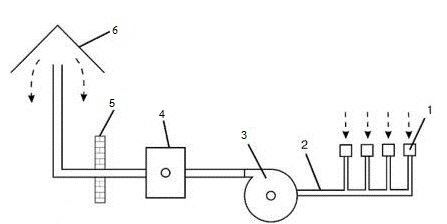

The figure shows a diagram that ensures the extraction of air masses using a radial fan.

Design

The simplicity of assembly and the availability of structural elements have become the reason that radial fans are assembled not only in the factory, but also at home. Indeed, the industrial assembly, although it has a guarantee of quality, is not always available in the price range and in the necessary configuration for small residential or utility rooms.

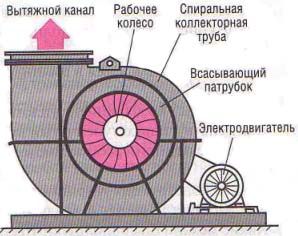

The design of a standard centrifugal fan provides for the mandatory presence of:

- Suction pipe into which the exhaust gas-air masses enter.

- The working (turbine) wheel equipped with radial blades. Depending on the purpose, they can be bent forward or backward from the angle of rotation. In the latter case, the bonus will be saving energy consumed up to 20%. They provide acceleration, and also set the direction of air movement.

- A spiral collector pipe or spiral casing, due to which the design is called the cochlea. It is designed to reduce the speed of movement of air driven through the device.

- Exhaust duct. Due to the different speed with which the air masses move in the suction pipe and in the spiral casing, a fairly strong pressure is created here, which can reach up to 30 kPa in an industrial environment.

- Electric motor.

The size of the cochlea, engine power, rotation angle and shape of the blades and other features depend on the scope and specific application conditions.

Operating principle

The efficiency of exhaust systems using snails is based on their simple principle of operation.

During operation, the electric motor starts the rotation of the impeller.

Due to the centripetal movement, the turbine wheel with radial blades is sucked through the nozzle and accelerate the gas-air masses.

The rotational nature of the centrifugal force of the blades is transmitted to their movement. This provides a different vector to the input and output streams.

As a result, the effluent is directed into the spiral casing. The spiral configuration provides braking and subsequent flow of a stream under pressure into the exhaust duct.

From the exhaust channel, the gas-air masses are discharged into the air ducts for further purification and emission into the atmosphere.

If shutoff valves are provided in the ducts, the radial fan can operate as a vacuum pump.

Views

The scale of the premises, as well as the level of pollution and air heating in them, require the installation of exhaust systems of the appropriate size, power and configuration. Therefore, centrifugal fans come in various forms.

Depending on the level of pressure created by the air masses in the exhaust duct, they are classified into fans:

- Low pressure - up to 1kPa. Most often, their design provides for wide leaf blades that are bent forward to the suction nozzle, with a maximum rotation speed of up to 50 m / s. The scope of their application is mainly ventilation systems. They create a lower noise level, as a result of which they can be used in rooms where people are constantly located.

- Medium pressure. In this case, the level of load created by the movement of air masses in the exhaust duct can be in the range from 1 to 3 kPa. Their blades can have different angles and tilt directions (both forward and backward), withstand a maximum speed of up to 80m / s. The scope is wider than that of low-pressure fans: they can also be installed on technological installations.

- High pressure. This technique is mainly used for technological installations. The total pressure in the exhaust duct is 3 kPa. The power of the installation creates a peripheral velocity of the suction mass of more than 80 m / s. Turbine wheels are equipped exclusively with backward curved blades.

Pressure is not the only sign that radial fans distinguish. Depending on the speed of the air masses, which is provided by the impeller, they are divided into two classes:

- Class I - indicates that the frontally curved blades provide a speed of less than 30 m / s, and the back bent - no more than 50 m / s;

- Class II includes more powerful units: they provide a higher speed for the driven air masses than class I fans.

In addition, the devices are manufactured with different directions of rotation relative to the suction pipe:

- oriented to the right, you can install by turning the case clockwise;

- to the left - counterclockwise.

The scope of application of snails depends largely on the electric motor: its power and the method of attachment to the impeller:

- it can gain momentum directly on the motor shaft;

- its shaft is connected to the engine by means of a coupling and is fixed by one or two bearings;

- by means of a V-belt drive, provided that it is fixed with one or two bearings.

Usage restrictions

It is advisable to install radial fans to move large volumes of gas-air masses, provided that they do not contain:

- explosives;

- fibrous materials and sticky suspensions in an amount of more than 10 mg / m3;

- explosive dust.

An important condition for operation is the ambient temperature: it must not go beyond -40 0From to +45 0C. In addition, the composition of the passing gas-air masses should not contain corrosive agents that contribute to the accelerated destruction of the duct part of the fan.

Of course, for use in some industries, fans are manufactured with a high degree of corrosion resistance, protection against sparks and temperature changes with housings and internal components from high-strength alloys.