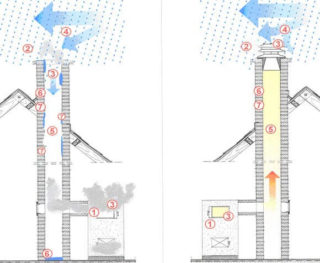

The density difference between cold and heated air leads to draft in the chimney ducts. The movement of fuel combustion products is natural due to vacuum or forced using fans. If you try to increase the draft in the chimney with your own hands, the efficiency of the boiler will increase. In small heating units, the natural movement of smoke is sufficient, and sometimes requires limitation.

Traction check

The anemometer device determines the traction force when the smoke moves at a speed of 1 m / s and more. In the off-season, the device shows unreliable results due to a small difference in the temperatures of the external and internal environment and a low flow rate. An advanced gas analyzer measures traction in pascals (Pa) and works accurately, but at a high cost. A reading of 10 to 20 Pa is considered sufficient.

The color of the fire in the firebox indicates traction:

- yellow and golden tongues speak of a normal flow rate;

- white flames and humming indicate that the draft is excessive;

- dark shades indicate insufficient speed.

The presence of gravity is determined by simple methods. A sheet of thin paper is brought to the hole in the chimney. His deviation indicates the movement of flows. Similarly, a burning match works, the flame of which should deviate from the vertical in the direction of traction. The smoke in the boiler room indicates the reverse movement of smoke in the pipe.

Causes of Bad Traction

A difficult situation arises if the chimney is designed and laid incorrectly. An inexperienced person incorrectly selects the diameter of the pipe or is wrong with the length. The smoke exhaust system must be rebuilt in order for traction to occur.

The draft is absent in case of violation of the tightness of the pipe joints, elbows, bends. You can increase the extraction of smoke by closing all openings through which hot air seeps. Clogging of the exhaust duct with soot also causes a decrease in draft or reverse movement of the combustion products. Sometimes heat exchangers of various designs are placed in the smoke removal duct to collect heat and reuse. But built-in installations affect traction and impair fuel combustion.

Traction decreases in conditions of:

- rain, fog;

- high humidity;

- high temperature outside;

- high wind speed.

Reverse draft or tipping occurs when there is no rarefaction in the chimney. Combustion products are not removed from the room into the atmosphere and are drawn into the boiler room, which is dangerous for humans by carbon monoxide poisoning.

Types of structures to increase draft in the chimney

The installation of technical devices helps to increase the removal rate. Mechanical and electrical devices increase and decrease the speed of smoke movement, while maintaining optimal pressure in the pipe.

You can increase the draft in the chimney if you install:

- rotary turbine;

- vane;

- electric fan;

- stabilizer;

- deflector.

The solution is selected taking into account the design of the smoke channel, the type of heating equipment. The height of the pipe above the roof level and the presence of multi-storey buildings in the neighborhood matter.Any device on the pipe causes soot and condensation to accumulate inside the channel, so it is better to design and install smoke exhaust channels.

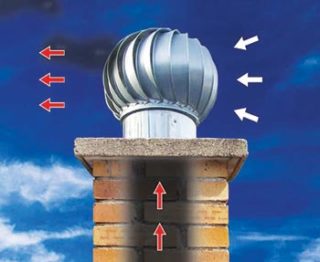

Rotary or rotary turbine

The traction amplifier contains one or more rotary devices in the structure, is placed at the end of the pipe and functions due to the movement of the wind. The temperature of the exhaust smoke should not exceed 150 - 200 ° C, depending on the type of turbine. More often such devices are placed on gas stoves and boilers.

The device rotates in one direction and rotation creates a region of reduced pressure above the top of the channel. The nozzle additionally protects the outlet from debris and precipitation.

The disadvantage is the inability to work in calm weather. The turbine continues to rotate when the heating is off during the summer months and creates increased traction in the room.

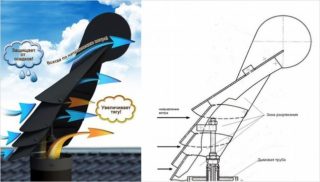

Vane

The nozzle on the chimney to increase traction is made in the form of a weather vane, which turns against the wind due to a special design. The chimney's task is to counteract the reverse draft and give the pipe head an aesthetic appearance.

Construction details:

- central axis;

- figure;

- Rose of Wind.

The cap has bearings inside that require regular lubrication. In frost, ice appears on the surface of the case, it must be knocked down.

The weather vane deflects the wind currents and prevents them from entering the channel, and the smoke freely leaves the leeward side. The design protects from rain. Special droppers direct condensate jets along the inner surface of the housing and prevent them from flowing into the pipe.

Electric fan

It is used to extract smoke from solid fuel, gas boilers, stoves, baths and saunas, fireplaces, open hearths, with the temperature of combustion products not higher than 200 ° C, as well as in the air purification system. The fan in the chimney to improve draft is a blower device to increase heating efficiency. The installation of the device allows you to make the boiler furnace and other elements compact, and the combustion process does not depend on the weather.

The speed of gas circulation increases, air supply to the burners is organized, air is distributed evenly over the combustion zones. The use of a fan is not always justified in small household stoves, boilers of low power, because they make the structure complicated and depend on electricity.

Stabilizer

The device is a chopper for dosed oxygen supply and maintaining traction in the chimney. The design has a safety valve to stop operation at overpressure in the pipe.

The stabilizer is installed on the chimney outlet and performs the following functions:

- stabilizes the pressure in the furnace;

- weakens excess draft in a pipe and improves boiler efficiency;

- protects the room from the occurrence of reverse suction of smoke.

A traction sensor is mounted under the umbrella head, which responds to an increase in the temperature of the combustion products. Smoke builds up under the dome when flow is weakened and heats the controller, which interrupts the gas supply to the burner.

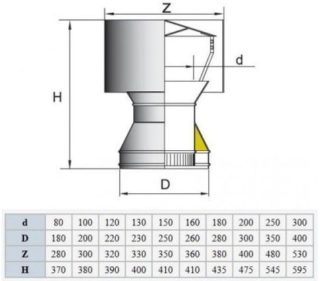

Deflector

The device is placed at the end of the pipe and converts the energy of the wind flow to reduce the static pressure in the channel. The Bernoulli effect is used, which consists in the fact that with an increase in wind speed and a decrease in the diameter of the channel, rarefaction appears in the pipe and additional traction force is created.

The standard version requires three parts:

- the upper cylindrical body, having an extension below, it is attached to the base using racks;

- bottom metal glass; sometimes asbestos cement or ceramic is used as a material;

- conical cap.

Above and below the deflector, ring-shaped rebounds are placed to prevent gusts of air. Some options are performed without the upper case, then the deflector consists of a lower cylinder, a diffuser, a reverse and a direct cap.

DIY deflector manufacturing

The walls of the upper cylinder take wind pressure and direct air bypassing, the intake of smoke is obtained by sliding along the inner surface of individual jets. The deflector can not be attributed to the group of fans, because the device has a simple shape and does not have working mechanisms.

On the cardboard, the contours of the parts that have been calculated and plotted on the drawing are drawn and cut out. Using patterns, parts are transferred to the metal with the addition of 1.5 - 2 cm along the edges of the lines for ease of assembly. Structural elements are obtained in expanded form after cutting with scissors for metal.

Strips of metal or corners are cut with a hacksaw to connect the parts into the finished product. The prepared parts are bent and folded in accordance with the drawing. When assembling, the elements overlap and are connected with rivets.

Necessary tools

In the manufacture of materials and tools are used that do not require professional skills from the master:

- rubber or wooden mallet;

- scissors and a hacksaw for metal;

- ruler, tape measure;

- chalk for drawing lines on a metal surface;

- electric drill, rivet gun;

- drill bits for metal;

- pencil and ordinary scissors.

The material is thin galvanized steel, a metal strip or a corner of a small section. The size of the rivets is selected in accordance with the diameter of the drill. For mounting on a pipe, nuts and bolts are used.

Size calculation

A drawing is carried out on paper, which indicates the key dimensions for creating a pattern of a weather vane-traction amplifier for the chimney.

Ratio when calculating sizes:

- deflector height is 1.7 d;

- the cap width is taken equal to 2 d;

- the width of the diffuser is 1.3 d.

The symbol d means the diameter of the chimney (internal). Another aspect ratio will result in poor performance.

Features of increased traction depending on the design

If the device of the deflector on the pipe is not included in the design documentation, its installation is coordinated with the employees of the gas service. Only then can traction be strengthened using this device.

Deflector designs differ:

- TsAGI deflector;

- round fixture;

- plate type;

- in the form of a star;

- H-shaped device;

- turbo deflector.

The deflector model is selected according to the average wind speed in the area and the diameter of the chimney duct. The devices are only effective in the presence of wind, in calm weather they do not work and can reduce traction. Enhanced smoke removal occurs with a different direction of the wind flow, except for the horizontal one, when turbulences occur inside and the path to the combustion products is blocked. The problem is solved by installing a reverse hood.

Improvement in the chimney of a gas boiler

If gas is used for heating, not all models of deflectors can be installed, since some are intended only for installation in a ventilation system. In order not to block the flow of exhaust gases, you need to consult with specialists.

In systems with a gas boiler, a deflector-vane is used. It is designed so that smoke exits the leeward side and increases draft in the pipe. The device is made of heat-resistant metal, which resists heat and is not destroyed by condensate. The bearing assembly helps to avoid rotation problems.Chimney weathercocks are unstable in strong winds.

For solid fuel boiler

In wood and coal-fired boilers, a mechanical non-volatile device is used to regulate traction. The fixture eliminates the need for manual adjustment and saves fuel. The regulator coordinates the amount of oxygen supplied by opening the furnace flap.

Thermomechanical device automates the process:

- when burning fuel, the energy carrier in the system is heated and the liquid in the working cylinder of the device expands, puts the mechanism into operation and engages the spring;

- the lever weakens the chain, the shutter closes, and the air passage decreases, smoldering begins instead of burning;

- cooling of antifreeze leads to a reduction in the spring and the opening of the furnace door, the process is regularly repeated.

The device regulates draft, prevents heat exchanger overheating, coordinates pressure and provides independence from weather.

In the chimney of a garage stove

Such furnaces are capricious about traction, since almost all the heat is spent on heating the garage. The temperature of the exhaust smoke is not high, the channel does not warm up, condensation forms. You can prevent the phenomenon by increasing the height of the pipe (up to 2–3 meters). A cylindrical or circular cross section of the chimney is used to prevent turbulence. The pipe of the garage stove is insulated to improve traction.

At the end of the pipe, a shutter is installed, partially overlapping the perimeter of the pipe. The gate regulates the intensity of the flame during ignition. If you use a large amount of fuel, the heated smoke will go up in a large volume and at the border with cold air you get a kind of cork. On some models of ovens, a gate is sold as a set.

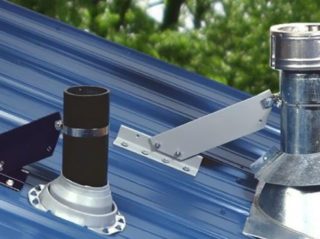

Deflector installation

A home-made and purchased model is assembled into a finished product below, before being mounted on a pipe. The aerodynamic structure is bolted to a round metal, asbestos pipe, usually for this 3 holes are made in the pipe. If there is a slight backlash, a grip clamp is used.

An adapter is used for mounting the deflector in a brick pipe of rectangular or square section. The device is tested after installation. The spark arrester is made independently from a thin metal mesh or stainless steel sheet.

The diameter of the structure should be larger than the outlet of the pipe so that the deflector does not fall into the channel and does not block the smoke exit. Rotary traction control does not work well in cold regions with heavy snowfall. Icing disrupts the operation of the appliance. Devices are mounted in accordance with technical standards and requirements.