Proper ventilation creates comfort and maintains a healthy microclimate in residential, public and industrial buildings. Insulation of ventilation pipes in a cold attic is one of the measures to ensure the working condition of air removal systems. The work is easy to do on your own, if you follow simple rules.

The need for thermal insulation

Without insulation of ventilation in the attic in the cold season, condensation forms on the inner surface of the pipes. The reason for its appearance is the laws of physics. Relative humidity at room temperature is normally 25–40%. In absolute terms, a cubic meter contains up to 10 grams. water.

Rising along the uninsulated ventilation duct to the roof, the air cools. At a temperature of –10 aboutC the moisture content may not exceed 1.5 g / m3. All "excess" water from a vaporous state passes into a liquid form. Condensation forms, which drops in the form of drops on the inner surfaces of the mines.

The appearance of condensation in the pipes entails unpleasant consequences:

- Freezing, water forms an ice crust in the pipes, internal clearance decreases. The draft is getting worse, the air exchange in the room is reduced.

- Metal channels are destroyed by corrosion.

- In brick ducts, moisture seeps into the cavity of the structure, where it freezes and expands. The brick is gradually collapsing.

- Under the ceiling, above the ventilation grilles, where the air flows are minimal, colonies of fungus and mold are formed and develop. Microorganisms spoil the finish, cause allergic reactions in people.

The lower the outside temperature, the more condensation will form. Therefore, the insulation of the exhaust pipe is an important stage of construction.

Characteristics and use of materials

Materials of different structures are suitable for warming ventilation ducts in a cold attic.

Criteria for choosing a heater:

- thermal conductivity suitable for the area;

- Fire safety;

- soundproofing properties;

- cost;

- manufacturability (simplicity) of installation on various pipelines;

- life time;

- resistance to mold and mildew, unsuitability for rodents:

- mechanical strength in the absence of external finish.

The colder the region, the thermal conductivity should be less. As an option - the choice of insulation of large thickness.

Fire safety is important if ventilation shafts pass near chimneys that heat up to high temperatures.

During the construction, each ruble is cherished, so the insulation should be chosen according to the price / quality ratio.

Manufacturability implies a short installation time using the minimum set of tools available in any household.

Sound insulation of ventilation ducts is important for tall houses and in areas with strong winds. Under certain weather conditions, the pipes emit an unpleasant howl, so it is advisable to close them with insulation along the entire length, and not just in the attic.

Mineral wool

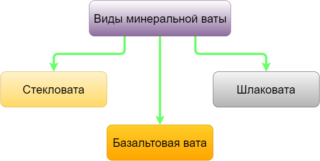

The concept of mineral wool refers to several types of materials made from different raw materials. Finished products are characterized by consumer properties and price.

Comparison of the characteristics of various types of mineral wool.

| Characteristic | Slaggy | Glass wool | Basalt wool |

| Thermal conductivity, W / (m2*TO) | 0,45 – 0,48 | 0,04 – 0,046 | 0,035 – 0,042 |

| Range of working temperatures, ° C | -60 – 240 | -60 – 450 | -180 – 600 |

| Fire resistance | incombustible | ||

| Moisture absorption,% per day | up to 2 | ≤ 1,9 | ≤ 1,7 |

| Release form | rolls |

|

|

Slaggy - the cheapest material of this type.Raw materials for production are waste from metallurgical plants. In civil engineering, it is not recommended to use this material, since during operation - when heated and wet - it releases dangerous chemical compounds, including phenol.

Slaggy - the cheapest material of this type.Raw materials for production are waste from metallurgical plants. In civil engineering, it is not recommended to use this material, since during operation - when heated and wet - it releases dangerous chemical compounds, including phenol.

In damp rooms, it absorbs a large amount of moisture, quickly cakes and loses the quality of insulation.

Glass wool made from battle and marriage glass containers. Having good insulation properties, the material requires compliance with safety measures during installation.

Glass particles irritate the skin, mucous membranes of the eyes and respiratory system. When installing, it is necessary to use the means of protection of the organs of vision, breathing, work with gloves and closed clothes.

The material is not resistant to mechanical damage and requires an external layer of protection.

Mounting on vertical surfaces achieves careful fastening to the base, since cotton wool loses its shape as it is used.

The average term before replacement is about 10 years.

Stone (basalt) cotton wool is produced from rocks with a small addition of chemical additives. Environmentally friendly product is easy to install due to its dense structure.

The process of thermal insulation using any type of cotton wool is expensive, since it will require the installation of an external layer of protection.

The warming algorithm of the roll option:

- The material is wrapped around the pipe without gaps or voids. Fasten for convenience with a thin soft wire.

- Around the wool, a layer of thick foil or galvanized metal is mounted.

- They tighten the structure with steel clamps.

The plates are fixed to the brick surface with dowels with wide hats or with a special cement-based adhesive.

The material must be protected from moisture.

Basalt cotton wool with a density of 50 kg / m or more3 can be plastered with cement compounds. After installation, the adhesive composition is applied to the surface of the plate and the plaster mesh is pressed into it. After complete drying, a cement-sand mixture is finished, which can subsequently be painted.

Polyethylene foam

Varieties of material are sold under the names: foam, isolon, thermoflex, etc.

Thermal conductivity 0.045 - 0.055 W / (m2*TO). Polyethylene foam practically does not absorb moisture, the service life of about 25 years.

Working with the material is very simple - the sheet is wrapped around the pipe and secured with tape. It is important to accurately carry out preliminary measurements so that there are no unprotected places - cold bridges.

There is foil isolon on the building materials market. Due to the metal layer, the sheet reflects up to 95 - 98% of heat, which improves the performance of insulation. Such sheets are fastened with aluminum tape or special glue.

Polyethylene foam belongs to the moderately combustible class and emits harmful substances during combustion - it is not recommended to use it near hot chimneys.

For smooth plastic or metal pipes, glue-based material is purchased, which facilitates installation - just remove the protective film and stick on the insulation sheet.

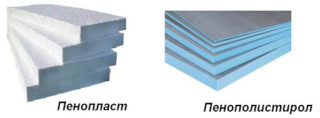

Expanded polystyrene

Two types of insulation are produced from polystyrene, which differ by the manufacturing method:

Two types of insulation are produced from polystyrene, which differ by the manufacturing method:

- foamed, it is often called polystyrene;

- extruded, some manufacturers call extrusion - expanded polystyrene, Penoplex, Technoplex.

Advantages of expanded polystyrene:

- low price;

- stability of characteristics at different temperatures;

- does not get wet and does not change properties in any operating conditions;

- self-extinguishing time after termination of exposure to an open flame - 4 seconds.

When heated, the material quickly collapses, releasing harmful substances, therefore it is unsuitable for places where chimney shafts pass.

The thermal conductivity of both types is the same - 0.032 - 0.05 W / (m2* K) and depends on the density. Operating temperature from - 50 to 65 aboutWITH.

The density and price of polystyrene is higher than that of polystyrene.

The structure of extruded polystyrene is harder and more convenient to use in work.

Insulation of ventilation pipes will save from rework in the next 50 years.

The process includes several operations:

- Sheets of polystyrene (polystyrene) around the perimeter are attached to the brick chimney with dowels. They are glued to the metal channels with mounting glue.

- Free cavities in the corners are filled with some kind of heat-insulating material, polystyrene foam.

- Foams close up the joints.

- They cover the material with finishing - metal, siding, etc.

For pipes of circular cross section, molded parts of different diameters are produced. At the joints, a thorn-groove connection is used, which simplifies installation, eliminates the occurrence of cold bridges. This method has one drawback - the details are released only to cover direct sections. Turns will have to be insulated in another way.

Synthetic rubber

By structure and characteristics, rubber is close to polyethylene. Available in the form of sheets, rolls, cylinders. Closed pores of the material make it completely water repellent. Thermal conductivity 0.024 - 0.038 W / (m2*TO). At temperatures from –200 to 180 aboutC retains all qualities.

Joints are sealed with special glue or tape.

Factory Solutions

In some cases, it is more convenient to use finished products of industrial manufacture.

A section of the insulated ventilation duct can be assembled from ready-made pieces of sandwich pipes. The design consists of two layers of steel between which a basalt wool insulation is laid. Elements are standardized in size (diameter and length).

When assembling, individual parts are simply inserted into each other.

Most of the products are made of stainless steel, so the service life is 15 years.

The work of warming the hood in a private house, done by yourself, will not take much time. Costs are small compared to the consequences that may result from inadequate ventilation. The right choice of materials and installation will make the ventilation work trouble-free for the entire duration of operation.