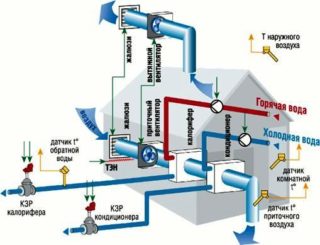

The supply and exhaust ventilation system works due to consumption and exhaust air. In winter, air flow heating is required to create a comfortable indoor microclimate. This task is performed by the air heater. Efficiency of work directly depends on the correctness of its installation and tying. For this reason, the connection is carried out in compliance with all rules and regulations.

Operating principle

A heater (duct heater) is a universal device that transfers heat energy from a heating element to the supply air. The device works like a heat exchanger. It consists of pipes through which air masses circulate. In pipes, thermal energy is transferred from one carrier to another.

When air enters the unit through the grate, the masses are heated due to heat transfer from the pipes. Next, a fan blows around the device and delivers heated air through a diffuser into the room. To make the device work silently, special sound-absorbing elements are used. When the unit shuts down, the valves block the access of cold air from the street to the system.

A heater cannot work without a strapping system. For its functioning, regulatory nodes that perform the following functions will be required:

- Work control. Parts provide a constant mode of operation and report failures.

- Ensuring uninterrupted operation of the heat exchanger. Emergency Alert.

- Temperature control and its adjustment. The temperature should be within the calculated values for uniform heating.

- Icing prevention.

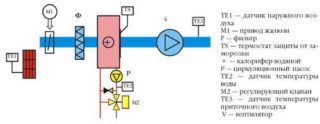

The system includes the following elements:

- Shutoff valves. These are taps for blocking the flow of coolant, which are made of durable materials (steel, brass). It is selected by the power of the device.

- Check valves. They are a barrier to the outflow of fluid. The choice is made according to the diameter of the pipelines.

- Actuator and control valves. They are the main and most important part of the harness assembly.

- Pressure gauge, thermometer.

- The crane for removal of air and discharge.

- Balancing valve.

- Pump.

- Filter. A mesh with a mesh size of 500 microns is used.

Installation of the system is carried out by specialists according to existing standards specified in SNiP, SP and GOST. First you need to create a drawing of a heater for the correct connection.

Varieties of heaters

Duct heaters are classified by type of coolant. The following types are distinguished:

- Electric. As a heating element, a metal heater is used, which works from the mains. The device is easy to install and install. The capacity is designed for room maintenance with an area of up to 100 sq.m

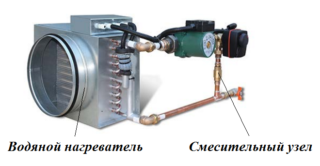

- Water. These are devices in which water circulates through pipes. It is used in ventilation systems in public and industrial premises. It is necessary to install a water heater bundle assembly.

- Steam. The steam-powered air heater has a high efficiency and a high heating rate. The steam is heated to a specific design temperature. Suitable for installation in industrial buildings with a source of water vapor. The binding of a steam supply air heater is complicated, therefore it is carried out only by specialists.

The choice of the optimal system depends on the type of premises, its purpose and capabilities.

Equipment selection

The elements that make up the system do not differ depending on the selected scheme. To choose the right components, you need to use the following recommendations:

- All fittings must comply with the technical specifications. They are calculated by the maximum value of temperature and pressure.

- The diameter of the elements must correspond to the size of the piping of the heating system.

As shutoff valves it is necessary to choose spherical cranes from steel or brass. For pipes with diameters over 50 mm, flange valves are required.

To simplify the work, buy cranes with union nuts. To limit the flow, check valves are selected that are placed on the return line or the bypass of the nodes.

To control temperature and pressure, manometers and thermometers are bought. The temperature sensor is placed on the supply and return lines in front of the heater. The pressure gauge is installed in the pump group.

To create the optimal movement of the coolant, put a circulation pump. It is mounted on an adjustable area, where it helps to overcome hydraulic resistance. The role of additional parts are filters, valves, valves.

Wiring diagrams

For efficient heating of the incoming air with a heater, you must make the correct connection. There are several installation schemes, which include:

- One ventilation circuit and one air heater. This is the simplest scheme in which one heating device is located at the inlet or any other section of the channel. Such a connection is used for seasonal heating and does not have a backup heat source.

- Two ventilation circuits and several heaters. This is a more complex scheme, suitable for installation in complex shape rooms. Suitable for year-round use. There are several strapping nodes. The first circuit is used for heating in the autumn-winter time, and the second for summer. Due to the large number of devices, the system can operate continuously even in the event of an accident at one of the strapping nodes.

The composition of the classic binding unit includes the following elements:

- Circulation pump. It is used in water systems and accelerates liquid through pipes.

- Condensing unit. It is used as an external unit in the piping of the cooling system.

- Temperature and pressure control devices.

- Locking mechanisms.

- Bypass

- Filter.

- Two-way or three-way automatic valve.

- Tubes, connectors and other parts to connect the mixing unit for ventilation.

The connection diagram of the strapping unit can be made using rigid and flexible eyeliner. Rigid eyeliner is the simplest metal pipe connection. Suitable when the exact location of the air heater is already known. Flexible eyeliner is the most complex and is made using corrugated pipes.

Temperature control

Temperature control is the most important task of the system. There are two ways to adjust:

Temperature control is the most important task of the system. There are two ways to adjust:

- Quantitative. This is an outdated method in which the temperature directly depends on the volume of the coolant.

- Quality. A more effective method in which the coolant is consumed linearly. This is done using a three-way valve and pump. There is no chance of leakage.

Specialists use the second method. It is compatible with any heater design.

Ventilation system

The choice of the optimal ventilation scheme is influenced by the required temperature, heating intensity, heat source, pressure difference. There are several systems:

- Harness the ventilation unit using a two-way valve.It is placed on the entry point without an additional heat exchanger. As a result, the valve acts as an intermediate buffer and dampens the pressure of the water flow. The disadvantages of the scheme include the risk of freezing at low temperatures. Pump installation required.

- Using a three-way valve. The result is two strapping systems. In the first case, water flows are separated, and in the second, their mixing. The scheme is used in autonomous heating networks.

In any design, installation of the hood is required. By maintaining a balance between the incoming and outgoing air flows, the calculated room temperature is maintained.