An air duct is a prefabricated structure used in forced or natural ventilation. They are necessary to maintain a good microclimate in the room, as well as clean air. For a system to function properly, it must be leakproof. Welding the ducts is considered the most durable and reliable, but there are other installation methods.

Duct classification

Design features of the system affect the choice of connection method. Also, the method of docking depends on operating conditions, parameters of the output of contaminated air.

Round and rectangular

The geometric shape distinguishes round and rectangular structures. The advantage of the first option is the absence of the risk of the appearance of vortex flows. The noise level is lower. This type of duct is more often used in industrial premises.

For residential buildings, a rectangular design is better suited. Due to its high throughput, it provides good ventilation. Such a system is easier to hide under the finishing material. Due to the tight fit to the wall, the product does not take up much usable area.

In rare cases, triangular sections are used to form the air conditioning system. They are important for the interior.

Rigid and flexible

Rigid ducts have different shapes: round, square, rectangular. For the manufacture of structures used aluminum, stainless steel, polymeric materials. Flexible options have only a round shape. They are made of aluminum, textile, PVC. A wire is used to give extra rigidity to the product. An effective system combines both types of ducts.

Air ducts are located inside or outside the wall. The first option is a ventilation shaft in a major construction. It is used in living quarters. The external duct is more suitable for industrial or technical rooms in which design is not always important.

Welding methods

To connect air ducts to each other by welding, the craftsmen have to rarely, as the process is expensive. This method is used if special requirements are imposed on the tightness of the structure. The welding process is manual or mechanized.

Manual

Arc welding is used if the thickness of the material is more than 1.5 mm. Gas equipment is necessary if the metal has a thickness of 0.8 mm. The second method is rarely used.

Mechanized

The mechanized welding method is semi-automatic or automatic. It is used in enterprises.

Connection types

The ventilation pipes are connected to each other by a welded or flange method. In addition, you can fix the elements with a bandage, nipple or sleeve.

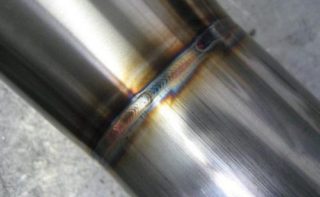

Welded

It is possible to connect fragments of the duct by welding if they are metal, while the thickness of their walls exceeds 1.5 cm. Most often this method is used in industrial premises in which harmful gases accumulate. In this case, the seams should be as tight as possible. Galvanized materials require highly professional welding to avoid corrosion in the weld area.

Nipple

A nipple is a part of a pipe in the middle of which a convex rib is present.It is inserted into the main structure. The same rib is used for fixation. A different section of the duct is worn on the product. The joint is sealed with metallic tape.

The nipple connection is carried out using a coupling. Its diameter is larger than the main pipe. The coupling can combine 2 fragments of the structure. The rib in this case is located on the inner surface of the element. This method is used to connect round ducts.

Flange

According to GOST, pipes can be connected by a flange method. For fastening parts, spot or continuous welding is used. Between themselves, the flanges are fixed with nuts and bolts, as well as rivets. To ensure reliable sealing of the weld, it must be stained. A gasket is placed between the steel elements. Despite the efficiency, the flange connection of the ducts is laborious to manufacture and expensive.

Bandage

The bandage method of connecting the structure is in demand at the enterprises of the chemical industry. It provides high reliability of the joint, but the manufacturing process itself is expensive, therefore it is unpopular for domestic use. The bandage is attached over the connecting seam. Before this, the ends require flanging. The shroud space is filled with a chemically inert sealant. This method is used to connect plastic ducts to each other.

Used equipment and materials

To create a nipple connection of ducts or a welded joint, the following tools and materials are required:

- stainless steel;

- tape measure, marker;

- hammer, pliers;

- vise;

- metal cutting tools;

- sealant and gun for its application;

- welding machine;

- pipe fragments of the corresponding diameter.

The mounting technology of the structure must be followed to the smallest detail. If you combine parts of the duct without sealing, the functionality of the system is impaired. The structure is connected to the hood, taking into account the diameter of all parts. Before installing the duct, a drawing is made of it.

Advantages and disadvantages of welded joints of ducts

The welded joint is one-piece and does not require additional fixing elements. It has the following advantages:

- the possibility of manufacturing large structures;

- weight reduction compared to cast elements;

- high strength and reliability of the joint;

- relatively low labor intensity in domestic conditions.

In a welded joint, residual stress often occurs. In this case, the technical properties of the metal change, which eventually loses its strength. If the welding is misused, the seams may be defective. After using the device, the joints must be checked visually and with the help of tools. With local heating of the metal in the area of thermal influence, the mechanical properties of the material can change.

Scope of application

Connect the air ducts to the hood in any room. Welded joints are used in smoke removal systems, moving air saturated with moisture or acid fumes. They are necessary in designs within which high pressure is present or hot air masses circulate.

This type of connection is used in basements, on attic floors. It is suitable for residential and technical premises. This type of duct installation is fireproof, durable and airtight.

Welded connection of the duct allows to ensure good quality ventilation. However, work must be carried out strictly according to the instructions.