A reliable centrifugal fan is considered one of the simplest and most convenient devices for pumping the right amount of air mass in offline mode. It is divided into several types according to the degree of pressure and type of construction. Before buying such a device, it is worthwhile to study its characteristics, specification and operation principle, as well as possible advantages and disadvantages in advance.

Design Features and Specifications

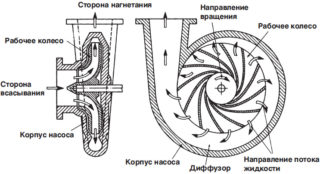

Centrifugal radial fan is a discharge type mechanism for generating pressure in a different range. Devices of this type are used in ventilation systems of industrial, municipal and commercial buildings in order to supply clean air and eliminate hazardous volatile components. They have the simplest possible structure, which includes a spiral-shaped case, an impeller, blades, and also an engine. The internal mechanism of the fan is set in motion due to the electric motor or the element responsible for the rotation of the shaft with the impeller. Devices of this category can be installed in rooms where certain conditions are met:

- maintaining the temperature at a level not exceeding 80 degrees;

- the content of mechanical components in the air is not more than 1 g / m3;

- the absence of fibrous particles and sticky substances in the thick of the air mass.

The rotary centrifugal fan is suitable for ventilation and heating systems of individual and multi-story buildings, agricultural filtration devices, and the delivery and purification of air in non-residential buildings. In addition, blowers are used in fire extinguishing systems and with the goal of accelerating the replacement of air masses in confined spaces. More economical are models with wheels, the blades of which are bent backwards, since they consume much less electricity and quickly cope with system overloads.

Before buying, you should know in advance what a centrifugal fan consists of in order to timely eliminate possible malfunctions if necessary and prevent an accident.

Principle of operation

Fans of this type are presented in two versions: with a radial or axial inlet for air intake. At the initial stage, the air masses go to the surface of the spinning impeller. Next, the impeller blades divide them and transfer them into the standard chamber, where air masses are compressed. At the next stage, the process of pumping flows in the chamber is started and the gas pressure rises.

The final cycle of the fan includes the removal of compressed gas to the outlet, after which air begins to flow into the central duct and moves in a given direction. During rarefaction, the air mass moves from the pipeline or from an enclosed space and then is discharged into the environment or an additional room.

Types of centrifugal fans

The principle of operation and the device of the fan directly depend on its type. Given the direction of movement of the air masses, such devices can be exhausted or equipped with a suction function on both sides. They are also distinguished in the direction of rotation, which is left or right. The main criterion is the air pressure inside the structure.

Low pressure

A pressure of up to 1000 Pa is considered low; such fans have a continuous spectrum of noise level, consisting of vortex and boundary noise. They are divided into two categories depending on the rotation speed of the main wheel, which is less than 30 m / s for the first and 30-50 m / s for the second class.

Medium pressure

Medium-sized devices create air flows with a pressure in the range of 1000-3000 Pa. They are installed in heating and ventilation systems designed for large rooms for various purposes. Such fans are equipped with inlets with a smaller diameter and number of blades compared to low pressure counterparts.

High pressure

Such devices are capable of creating an air flow pressure in excess of 3000 Pa, and are used for installation in systems for ventilating rooms with a large area, including storage, production and retail. They are also used for the purpose of issuing air masses in drying ovens, during installation of systems for pneumatic movement of goods and for other needs.

Constructive executions

The centrifugal standard exhaust fan is either floor or table, depending on the design. Variants of the first type are designed for large rooms, they are often used in production. Desktop models are more compact and easy to maintain; in addition, they do not cause problems during the installation process. Devices for ventilation also differ in the direction of motion of the stationary wheels, right-handed rotate clockwise, left-handed in the opposite direction. The wheels can be fixed in various ways and started using an electric motor or V-belt drive.

Selection rules

Experts recommend choosing models that require less energy and have maximum efficiency at the operating point. The device is selected according to a special schedule, giving preference to options that are closest to the specified parameters. In such a scheme, the operating mode or point is determined taking into account the intersection of this point with a straight line of equal efficiency, this selection method is the main one.

The point also makes the limit calculations of the ventilation network, in which tolerances for full pressure are taken into account. When choosing a centrifugal device, aerodynamic, noise and other options that are present in general type fans should be considered. The best option would be a noise-proof modern model, complemented by an exhaust hood and cooling system.

Before buying a device, you need to know in advance in which environment it will work. Conventional devices can operate at air temperatures up to 80 degrees in an air mass that does not contain chemically active substances. For use in harsh conditions, centrifugal asynchronous fans are used, the purpose and design of which allows them to cope with polluted air.

Advantages and disadvantages

Centrifugal devices differ from their analogues in a high level of productivity, allowing them to quickly and efficiently cool indoor air. Such models are completely safe and convenient due to downward flow of air, which makes them an ideal choice for industrial needs. The optimal ratio of price and quality makes it possible to use them in everyday life, choosing the right model for a specific interior design and individual needs. The list of the main advantages of centrifugal devices includes:

- compact dimensions;

- a small number of starting currents;

- ability to adjust performance;

- protection against excessive loads.

Centrifugal devices have virtually no disadvantages.Some users note a higher noise level of centrifugal fans, especially duct and kitchen fans, in comparison with similar devices.