Installation of a smoke ventilation system is mandatory for all large enterprises and places with maximum crowds. This type of system is designed to eliminate smoke and combustion products in enclosed spaces. Before installation, it is necessary to study in advance its functions and available types, rules for maintenance and operation in standard and hazardous conditions.

Definition of smoke ventilation and function

Smoke ventilation is a system that can remove smoke and hazardous combustible components from air masses. It is installed in rooms where there is no natural influx of fresh air, including in halls and passages, on theatrical stages, closed car parks and other spaces. To ensure the safety of evacuation, such systems are placed along the routes of people from potential places of ignition, for example, in halls and corridors.

In addition to its basic functions, ventilation of this type reduces the effect of smoke and combustion components on devices, materials and equipment. It provides fresh air into the production facilities, where work is carried out at night, as well as helps firefighters during extinguishing open fires. Standard or forced smoke ventilation should be installed in places where it is important to remove the effects of fire as quickly as possible.

Smoke ventilation equipment

In order for the ventilation system to fully fulfill its main and auxiliary functions, its design should include:

- channels of increased fire resistance, including collectors, shafts and air masses, ensuring the safety of equipment during ignition;

- high power fans, resistant to elevated temperatures and not able to deform under their influence;

- smoke ventilation valves installed at all points of the system, including those with fire protection;

- Doors and screens that are not exposed to gas and smoke, while preventing them from entering the building.

Smoke exhaust valves are the main parts of the system, they are evenly distributed around the entire perimeter and mounted under the ceiling. In addition to them, smoke exhaust devices are additionally installed, divided into parts, this measure prevents the formation of excess combustion components in the event of equipment breakdown or overload.

The requirements for ventilation systems for residential and industrial buildings are presented in SNiP. According to them, the power of devices cannot exceed 20,000 cubic meters. meters per hour, they can also function for at least an hour at 600 degrees and at least two at 400.

Types of ventilation systems

Smoke ventilation is divided into two main types and can be supply or exhaust. The first option works due to the influx of fresh air into the rooms, the second is responsible for organizing the air masses.

Supply

In the supply system, the valve draws fresh air into the room due to the action of a blade or radial fan. Air masses provide excess pressure, which is equalized after the opening of the channel, stretched beyond the walls of the building.To normalize the pressure, you can also use door or window openings, if they are present in the room.

Exhaust

During the operation of the exhaust system, the blade or rotary fan generates a force inside the duct, which connects the street and the serviced object. At the second stage, pressure equipment creates a weak discharged effect, after opening windows or supply valves, the pressure inside the building returns to normal. In addition to the mechanical stimulation of the flow in such ventilation, it is possible to use a draft of a natural type after installing a vertical duct on the facade or wall of the building.

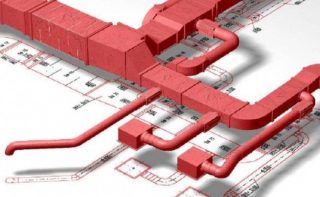

Aerodynamic calculation and design

To develop a system design, an aerodynamic calculation is carried out, which allows you to find out the size of the cross section, the flow rate of the mixture removed from the room, and also determine the potential pressure loss. In order to avoid possible errors, the shape of the section and the material of the device, as well as the roughness of its walls, are additionally taken into account. The air flow in a round and rectangular device will be different even if there is the same diameter and equal speeds. Roughnesses in the walls affect the calculations of the speed of air masses, the correction factors in this case may be too large.

In the process, the ventilation system is divided into several sections and determine the air flow at each of them, then add the numbers together. Next, you need to identify the longest chain of sections, which will become the main direction. Its parts are numbered, starting with the smallest, and enter the obtained parameters in the table. The cross-sectional area is determined by the formula and take into account that the speed of the air masses will not be the same in different areas. At the final stage, equipment is selected taking into account the results of the calculation, the processing scheme of the air masses and the requirements for energy efficiency.

In the finished project, all the features of the system should be presented and each service area defined. It marks the points for installing chimneys, intake grilles, duct lines. Installation of ventilation can be carried out only on the basis of drawings and diagrams approved by members of a special commission.

Systems installation and management

Installation of a separate or joint smoke removal system is carried out in several stages. First, you will need to examine the object, identifying the possible dimensions of the fire and the composition of the flue gases. At the second stage, they calculate the performance, determine the mounting points for fans and other elements. It is important to analyze in advance the degree of permeability for fences, as well as the resistance of materials to higher temperatures and their differences. Installation of ventilation is carried out step by step:

- laying of welded air outlets;

- installation of fans to remove smoke, control panels and valves;

- air handling by fire-retardant components;

- testing the system and putting it into operation.

Tests and acceptance are carried out by members of a special commission who test all sections of the system and check the operability of its elements for compliance with standards. If there are no problems, they draw up an acceptance certificate, sign documents and put the complex into operation.

Smoke ventilation maintenance

System maintenance is a rather complex and time-consuming task. In large enterprises, this procedure is carried out by dedicated groups responsible for the control and operability of ventilation. The list of their tasks includes checking the condition of the equipment once a week and its performance once a month, a full quarterly inspection, as well as annual regulations.All work of this type is entrusted only to specialists with the appropriate qualifications. Most often, they are members of licensed groups that make up system maintenance contracts.