To protect the motor and fan of the cleaning equipment in the kitchen, a carbon filter is used for the hood. The membrane cassette protects the unit motor and turbine blades from damage and wear as a result of contamination with solid dust and grease particles and gaseous impurities. A high-quality cleaning element extends the operating time of the exhaust motor by 18%.

Design and principle of operation of the carbon filter

Several stages of cleaning free air from kitchen aromas and impurities. When the membrane filler in the element is clogged with grease and dust, it is necessary to replace the link with a new component. As part of the exhaust system, sensors are used that determine the degree of contamination and signal the need for replacement.

The filter works according to this principle:

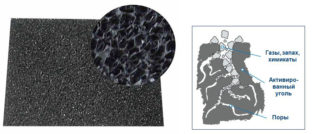

- The air stream penetrates through a dense diffuser, impregnated with a carbon solution or interspersed with active carbon. Part of the dirt accumulates in the tissue.

- Partially treated air passes into the cassette where the granules are located. Activated carbon traps the remaining impurities and absorbs pungent odors.

The design also determines the cleaning efficiency and affects the pressure loss in the pipe. Fine filling creates additional resistance to flow, and large granules facilitate the movement of jets. Corrugation of the membrane leads to an increase in the contact area with the carbon surface and makes cleaning more efficient.

The material of the filter frame is plastic or metal. The cassette made of a polymer material can be round, square or rectangular, the gap is filled with granules or a powdery substance. A high density tissue septum is impregnated with activated carbon or includes particles of material. Elements are disposable, they cannot be cleaned or washed, you can only change.

What is a filter for?

The purpose of cleaning cartridges is to absorb gas molecules with a porous filler inside. Activated carbon productively eliminates semi-volatile and volatile organic substances with significant molecular weight. The degree of porosity of the filler determines the efficiency and operating time before contamination.

The equipment above the gas stove is additionally equipped with mechanical pre-cleaning links that delay the particles. Fatty impurities that have passed through the first threshold accumulate in the carbon filter and approximate the replacement time. If the hood operates in a continuous ventilation mode, carbon filters can be omitted.

Users can make a carbon air filter with their own hands, using building materials and outdated frames that need to be restored, sometimes plastic pipes are used.

Operating procedure:

- Take 2 pieces of sewer pipe with a diameter of 75 (length 37 cm) and 100 mm (length 35 cm).

- In the walls of a wide pipe, holes with a diameter of 5 - 7 mm are drilled (over the entire area). Similarly, on the surface of a piece that is already, holes are made in the size of 12-14 mm.

- The body sections are tightly wrapped on the outside with agrofibre, the ends are sewn with kapron thread, a masking net is applied over the layer, connected with plastic clamps.

- Pipes are inserted into each other, a sewer plug is put on the wide end, fixed with glue or sealant. Between the walls, 5.5 mm of coal is poured.

AR-B coal is sold in 25 kg bags. The reverse side of the structure is protected by an adapter on the glue. It is connected to the hood by the protrusion of a narrow pipe, which protrudes by 20 mm.

Positive and negative properties

The main advantage is excellent work results and high-quality air flow purification. The positive aspects include the fact that when replacing, you can easily remove and put in a new element without involving a specialist. Changing the cartridge takes little time and the hood is practically not inoperative.

Domestic and foreign companies produce various models designed for hoods of all kinds. Coal cassettes are placed not only in kitchen equipment, cleaning units are used in supply and exhaust ventilation systems in private buildings and industrial facilities.

It is possible to choose a budget option or install effective protection with a high-quality filter element. Smells falling into the ventilation trunk of a multi-storey building will not annoy the residents of neighboring apartments.

Carbon cleaners are disposable, unlike aluminum cassettes, which can be washed and reused.

How to install a carbon filter in the hood

To install the filter, you need to read the instructions in which the process is described in detail. There are nuances to which you should pay attention. For example, a cartridge placed on the wrong side will not purify the air.

Standard instruction:

- the filter is unpacked and the fixing bracket is fixed;

- the door leans back and the element which catches fat is removed;

- the carbon component is put in place in the unit and screwed;

- the grease filter is put in place, the flap closes.

Some hoods contain two carbon cleaners in the design, located on both sides of the engine. In this case, a similar process is performed twice.

Rules for choosing a charcoal filter for hoods

Before purchasing a hood, you need to consult with a consultant on the availability of replaceable cartridges on sale. When buying cartridges pay attention to the manufacturer's recommendations. Carbon filters are manufactured to fit many types of hoods. But some models are inserted only in one type of equipment and are not suitable for another. Often this applies to new filters that are just released to the market.

Sometimes users insert soft cloth elements into the hood, which are of low cost. Gross violation leads to premature wear of the motor and fan. In the passport of the hood there are compliance parameters that must be considered when choosing a cleaning cartridge.

Popular manufacturers

Firms that produce kitchen cleaning hoods produce different types of carbon filters. Companies offer devices for typical rectangular hoods and for corner and wall options. Many models are equipped with grease trap nets and include several charcoal cleaners.

In such equipment, the performance of the filter corresponds to the productivity of the fan or slightly higher than this characteristic. Well-known manufacturers always indicate the duration of coal barriers, which must be considered when installing them. If the hood is able to handle 250 m3 of air, and the filter can let in 500 m3, the cleaner must be replaced after six months, not three months, as indicated in the instructions.

Products of the Greek company Elikor, Spanish Cata, Italian Elika are sold in almost all stores. High quality and affordable cost have made them popular. Coal gaskets are changed every 4-6 months, even if the hood is used with a constant load.Good work is manifested in the fact that there is no fat deposits on adjacent walls and objects.

Folter

The company has its own production base for the production of a wide range of coal cleaners. The entire proposed model range meets the accepted standards defined in GOST and technical specifications. Most samples are universal and suitable for equipment of various companies.

The kit includes materials:

- ion-exchange resins in the form of synthetic compounds of a macroporous structure, providing air purification;

- chemisorbents that absorb organic matter on its own surface;

- Activated carbon.

Folter products reliably and efficiently work for a long time, conveniently changing after the end of their life. The average duration of functioning without loss of quality is 5 months. Popular models are FyaS-S-K and FyaK-SP, which productively clean the supply air from odors. The average price of products is 2 thousand rubles.

Crown

The German manufacturer produces high-quality cooker hoods. Each unit is equipped with a Crohn filter element that purifies air from exhaust gases and greasy impurities. The hood housing is hermetically sealed, so the streams flow directly to the treatment barrier.

Filters are placed in the boxes of industrial and household ventilation, in the production shops they 100% remove toxic impurities, unpleasant odors, gaseous pollution and chemically aggressive fumes.

The filter element includes:

- activated carbon of stone, impregnated, peat, coconut origin;

- silver ions;

- compressed granules of the sorbent.

Compact devices are made tubular, panel type. They guarantee productive cleaning, with minimal pressure loss. No carbon granules are ejected from rigid membranes. The cost of a set of two drawer cassettes is 1590 rubles. Spare items are not included in the sales package and are purchased if necessary.

The service life is about 100 - 125 hours with constant use. Models are equipped with an indicator that shows the degree of contamination and the need for replacement. It is combined with units SLIM 600 inox MB, Janna, Kamilla (1 motor), Elma, Freya, Betty, Helen, Jasmin push button, Ester, Mara push button, Sabrina.

Jet air

The products of the Italian company are in demand due to energy efficiency and high performance. The filter elements are suitable for units manufactured by Jet Air and are used in other ventilation equipment. The material of the frame is metal or plastic. It is recommended to change the filters within the prescribed period, because the accumulated pollution can subsequently be drawn back into the kitchen.

Popular models are in demand:

- F00169 / 1S. The sample has an ergonomic design, combined with many varieties of cleaning units for the kitchen. The cost of the kit is 570 rubles.

- F00307 The device works for 4 - 6 months, the carbon filter is installed and removed for exhaustion with your own hands simple and convenient.

The company produces cleaning elements for kitchen appliances and for installation in the filter box of the ventilation system (at the beginning or end). Such devices use durable granules that do not weather during operation. The elements process the supply and recirculation flow, reduce the level of gaseous impurities and pungent odors.

Hansa

Hansa, a manufacturer from Italy, produces high-quality coal cleaning cassettes. Filters do not belong to universal models, therefore, before purchasing, you need to check with a consultant whether a particular hood is appropriate. The cost of one product is 1600 rubles.The high price is due to the quality materials used in the element.

The most popular among buyers is the model KF17203. Instance with a diameter of 175 mm is suitable for Hans hoods OSP622H, OTP616WH, OSP622WH, OTP627WH, OTP6221WGH, OTP616IH, OTP6651BGH, OTP627IH. The service life is 6-12 months with regular inclusion of exhaust equipment.

Corrugated polyester, in which activated carbon particles are embedded, is used as a membrane. The barrier collects solid impurities on the surface, and impregnations are cleaned of gaseous substances and unpleasant odors. For non-standard equipment, the company carries out custom filters.