Air ducts move gas-air mixtures, and also supply clean air in a given direction. They differ in the shape and size of the section, long, material, installation methods and the nature of the operation. Often, different types of air ducts are combined into a single ventilation scheme, creating branches, branches and sleeves. Rigid and semi-rigid metal ventilation pipes are most in demand in industrial and civil construction.

Duct classification

Ducts are installed in ventilation systems of a wide variety of characteristics. Therefore, there are many types of ducts, they are combined into subgroups according to the following qualities:

- sectional shape (can be square, oval, round, rectangular);

- cross-sectional diameter (there is a standard set of diameters for different types of cross-sections; air ducts of any diameters are made for special ventilation);

- material (sheet metal, plastic, metal);

- construction (straight-line-seam or spiral-spiral);

- rigidity;

- fastening method (on or without flanges);

- type of fastening (bends, tees, turns).

Duct selection

Sectional shape

The most popular cross-sectional forms used in the construction of ventilation are rectangular and round. In some cases, only flat ducts for ventilation can be installed. They are made from round pipes, compressed into an oval on special equipment.

The production of round ducts is cheaper, they use less material and the technology itself is simpler. For example, for the manufacture of a rectangular metal duct, 25% more metal will be used than a round duct for ventilation of the same size and throughput. This is explained by the fact that a pipe of rectangular cross section is assembled from several patterns.

The advantages of round ducts:

- excellent tightness;

- high aerodynamic properties (there are no obstacles to the passage of air);

- silent work;

- easy to install;

- weigh less than rectangular.

The main advantage of rectangular (flat) ventilation ducts over round ones is that they fit more easily into a limited space. Therefore, with lower aerodynamic qualities and more noisy operation, rectangular ducts are more often installed in offices, country cottages, that is, in relatively small objects.

The listed advantages put round air ducts in the first place in industrial ventilation. Some manufacturers claim that it is more profitable to install 2 round ducts in parallel in ventilation than 1 rectangular or flat one. This statement is true for a direct ventilation network. With many branches, approximately a third of the trunk area is in fittings, which are quite expensive.

Diameter of the duct section

The dimensions of the ventilation ducts depend on the design values of the flow velocity. So, for residential premises, speed is limited to 4 m / s. Otherwise, a rumble will disturb people.

If the speed of movement is known, then the cross-sectional area is determined by the formula:

Smin=0,9 * L,

here: L - air flow in cubic meters / hour, Smin - the minimum cross-sectional area of the duct in sq. centimeters.

According to the regulatory requirements set forth in BCH 353-86 and SNiP 41-01-2003, round galvanized ventilation ducts are made in the following diameters in mm: 100, 125, 160,140, 200, 180, 225, 250 to 2000 mm. The dimensions of the cross section of rectangular ducts are also regulated: 100 - 3200 mm.

Design

Structurally, ducts are fold or straight-seam, spiral-welded and spiral-wound.

Longitudinal air ducts also called industrial, they are made from a solid metal sheet with a length of 1 - 2.5 meters. Sheets of steel with a thickness of 0.5 mm - 1.2 mm are used. The suture joint increases the stiffness of the galvanized duct for ventilation, so it is often placed on a bend.

Spiral-wound (castle) pipes are made of metal tape (strip) up to 1 mm thick. The width of the strip is not more than 13 cm, the length can be any. The tape is folded in two ways: in tape or in a ring. The second manufacturing method is more expensive, but stainless steel ventilation ducts are much higher quality.

Spiral welded galvanized air ducts for ventilation are made from templates with a width of up to 0.75 m and a sheet thickness of 0.75 - 2.2 mm. The edges of the pattern overlap and weld. The result is a durable, airtight seam.

Materials

Galvanized Steel Ventilation Ducts They are used to transport air of standard humidity, heated to no more than +80 degrees, without impurities of active substances. Zinc protects steel from oxidation, increasing the service life by several tens of years, significantly increasing the price of the pipe. The fungus does not develop in galvanized air ducts, so they are good for working in high humidity conditions (canteens and restaurants, swimming pools, showers).

Stainless Steel Ventilation Ducts transport air masses heated to +500 degrees. For industrial ducts use thin-fiber, heat-resistant steel, resistant to aggressive substances. Wall thickness can reach up to 1.2 mm. Corrosion-proof ducts are expensive, but the most durable ventilation is assembled from them. Most often they are installed in industries associated with the release of heat, radiation, abrasive particles.

Plastic ducts also good for ventilating active gas mixtures. They are installed in pharmaceutical, chemical, food factories, in laboratories. Typically, plastic ventilation ducts are made from PVC (modified polyvinyl chloride). It withstands contact with moisture, fumes of alkalis and acids. Plastic ventilation elements create tight joints, they are lightweight and have a smooth inner surface. In ventilation systems, propylene ducts are sometimes installed.

Plastic ducts include 2 layers of metal foil interlaced with foamed plastic. Metal ducts do not need thermal insulation, are lightweight, very strong and look attractive. Compared with polypropylene ventilation ducts, they are quite expensive, therefore, they are used only to a limited extent.

Vinyl ducts are unrivaled resistance to chemical elements. Like polypropylene ventilation ducts, they can be bent at any angle, they are durable and light.

Fiberglass Ducts They are used in the ventilation of chemical plants for the transfer of alkali and acid vapors, as well as for the internal ventilation of galvanic shops. Fiberglass pipes can be installed outside the building, they are resistant to ultraviolet, unlike cheaper plastic ducts for ventilation.

Rigidity

Mostly ventilation systems equip rigid ducts round or rectangular cross-section with additional thermal insulation with basalt wool. Such ducts provide highways tightness and strength. Plastic pipes are produced on extruders, and metal pipes on profile bending machines. Rigid ventilation ducts are easy to install and have high rates of air movement. When creating an extensive branched network of ducts, it is necessary to calculate its total ventilation weight and pre-select reinforced fasteners.

Flexible ducts for ventilation are made in the form of a corrugated sleeve. The duct frame is a rigid steel wire twisted in a spiral and coated with a laminated foil or polyester. Often the walls of flexible ventilation ducts are layered. The advantage of the flexible pipe is its unique ease of installation, repair and transportation. The pipe can be bent in any direction, it is repeatedly compressed and stretched, new bends can easily be connected to the finished system, it can withstand up to +140 degrees (foil), up to +90 polyamide.

A serious minus of flexible air ducts is the corrugated inner surface. It creates obstacles to the air, reduces its speed and causes additional noise.

Semi-rigid air ducts incorporate the best qualities of flexible and rigid pipes. They bend and are very durable. Semi-rigid air ducts are made from rolled metal strips (aluminum). Semi-rigid air ducts withstand up to +300 degrees, and steel up to +700, so they can also be used for smoke removal systems.

Unlike flexible ducts, semi-rigid stretch only once, after which they do not compress. The presence of spiral seams also negatively affects aerodynamics, reducing the inner diameter of the ventilation duct. Therefore, in complex ventilation systems, semi-rigid ducts are not used.

Methods and types of mounts

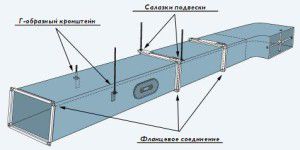

To connect the ventilation ducts most often use flange and bandage (waferless) mount. It is advisable that the ventilation system has as few duct connections as possible.

At flanged type at the ends of the ducts and fittings are flanges that are fastened together by riveting or self-tapping screws. Rivets are placed every 20 cm, in some cases they use welding. The flanges are sealed with rubber gaskets, a tight connection of the ventilation ducts is created.

Waferless the method consists in the fact that a bandage of metal battens and strips of thin metal is applied to the joint. This method is more economical since less metal is consumed; installation of ventilation ducts is faster.

Duct Installation Rules

Before installation, the ventilation system is divided into enlarged units, the length of one node cannot exceed 15 meters. The nodes are collected according to the following algorithm:

- Mark the places of holes and fixtures on the ventilation ducts and shaped elements.

- Make holes.

- Fixes are fixed and bolted, all joints are sealed with special compounds or tape.

- Shaped elements and ventilation ducts are mounted in enlarged units.

- Fix clamps and fixtures.

- Raise the finished assembly and hang it on the finished hardware.

- Attach to the previously installed section of the ventilation duct, the joints are sealed by diameter.

Installation of flexible and semi-rigid ventilation ducts is easier compared to rigid galvanized ones. Pipes are much lighter, turns and bends do not require special work, special attention should be paid to the connections of ventilation ducts, insulation and sealing of joints.

- Before installation, the flexible duct is fully stretched;

- The passage through the walls is carried out only with the help of special adapters (sleeves);

- The duct must not come into contact with the heating pipes;

- When stretching a flexible duct, it is necessary to observe the direction of air movement indicated on the pipe and packaging;

- The bending radius of the flexible duct must be at least 2 diameters;

- To connect the sections to each other, foil tape, plastic clamps, suspensions, clamps, etc. are used. All joints must be sealed;

- The size of the ventilation duct must match the diameter of the clamp, if the clamp is too small, the internal section is compressed;

- The distance between the mountings of the ventilation ducts can be 1 meter for horizontal placement and 1.8 m for vertical;

- The permissible sagging of the flexible pipe is 5 cm per meter long.

With many advantages, flexible pipes are used in ventilation to a limited extent. For example, they are not suitable for vertical highways with a vertical drop of more than six meters.

Installation video for a flangeless duct: