According to the regulatory documentation: SNiP and safety standards for the creation of ventilation systems, the air exchange rate is regulated, in terms of the number of toxic components.

Process description

For an effective estimated characteristic of air exchange in a building for industrial use, the value “kV” is used. This indicator of air exchange is the ratio of the total volume of air that comes in "L" (m3 \ h) to the indicator of the total amount of cleaned space in the room "Vn", (m3) The calculation is carried out on the adopted time period.

If during the design, all calculations and the project itself are organized correctly, according to the standards, then the rate of air exchange for industrial premises will range from 1 to 10 units.

In addition to the calculation formulas and the theoretical basis, in order to determine the required indicator, experts advise to conduct research on natural conditions at similar operating enterprises, on which there are actual data on emissions of toxic fumes, gases, etc.

To determine the rate indicator, industry-specific documents, building codes and sanitary standards are used.

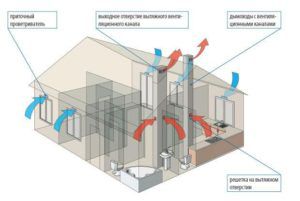

Air circulation in industrial buildings

When constructing and planning buildings for future industrial needs, it is necessary to correctly calculate the ventilation routes in the rooms and determine the process of air circulation. To do this, you need such a characteristic as the rate of air exchange, which is determined by the tabular data on the presence of toxic substances in the space: oxides, acetylene oxides, etc.

When calculating the process of air circulation in a building, the amount of heat released is taken into account in such a way that the amount received, greater than the norm, can be removed year-round without difficulties and obstacles.

To reduce the rate of excess heat, aeration is used. Such a process has become widespread in the field of the chemical industry, for example, at thermal production sites. In this case, the air exchange rate in the warm season reaches 40-60 points due to aeration.

With such indicators of air exchange, the organization of airways, meteorological standards are achieved, provided for by the standards of sanitation.

So, directly arranging and erecting premises subsequently affects the estimated air exchange rate, for this special working openings are provided that can be opened, guaranteeing the possibility of workers to get fresh air and remove unfavorable elements.

Determination of the rate indicator

Performing production and technological calculations for the main premises, the installed large equipment is not taken into account. For example, if pumping units are installed at the main production, without specialized exhaust ventilation, then the amount of harmful gases in the atmosphere will be 6-7 times higher than those limited by official standards.

In auxiliary, additional production rooms, except for washing compartments, the air exchange rate is calculated based on the indicators of the exchange rate.

An emergency ventilation system must be provided at the factory, which ensures the prompt removal of a high concentration of harmful and toxic particles from industrial buildings. Such a system is relevant when deviating from the established norms of the production route of manufacture and in emergency situations. In order to exclude the possibility of the passage of unfavorable components through the connecting paths in the building, it is recommended to organize emergency-type output paths without the compensation component of the inflow.

Multiplication table

Normative documents for calculating air exchange

The multiplicity of the air exchange of the exhaust hood communication system is formed on the basis of industry safety data and regulated sanitary standards. The air exchange rate is set for a particular room individually, according to the design information in the project.

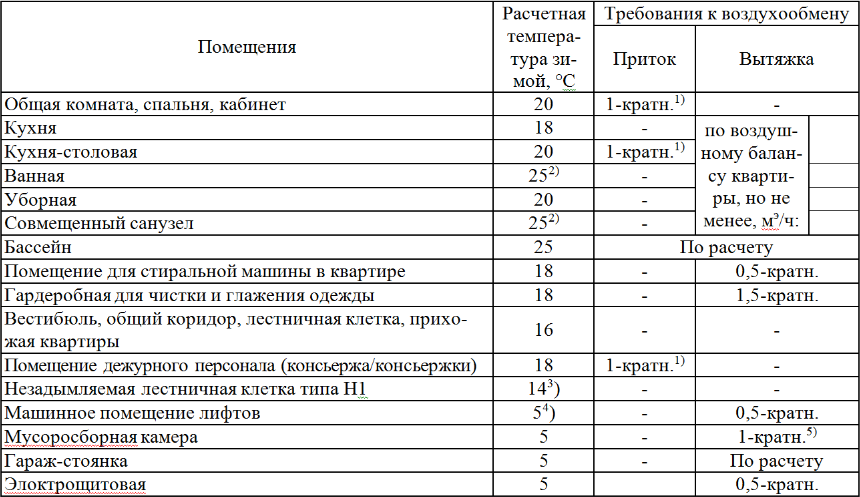

In SNiP, TB and specialized standards of each specific industry and industrial design and construction, different information is given for the frequency of air exchange (hourly). All values are given depending on the type of industrial premises:

- additional facilities for auxiliary purposes;

- Workshop areas.

So, the corresponding SNiP regulates the characteristics of numerical values (calculated) for auxiliary premises of a production type.

Also, the values of the air exchange rate are listed in SNiP P-92–76, for secondary buildings.

With the constant formation in the industrial zone of toxic gases and an increase in the degree, the maximum prescribed value for each type of adverse production harmful emissions is taken as the multiplicity norm.

So, having in stock the value of the total volume of the room (m3) and the rate of air exchange, using simple mathematical formulas, you can calculate the required amount of incoming air for a certain zone, per hour.

L = n * S * H,Where:

L - required productivity m3 / h;

n - air exchange rate;

S - area of the room, m2;

N - room height, m.

Air exchange rates for industrial premises

For industrial-type buildings, a general ventilation system is provided, the needs of which are calculated based on the conditions of a particular production and the availability of a certain amount:

- heat;

- liquid or condensate;

- harmful particles.

If there is equipment in the room with gas or steam emissions, the amount of necessary air exchange is calculated taking into account the emissions:

- from this equipment;

- paved communications;

- provided fittings.

All necessary indicators are laid down in the technical documentation of the room, otherwise the data is taken from the actual parameters. This calculation is regulated by the BCH21-77 and the corresponding SNiP.

If, during calculations, the air exchange ratio exceeds ten times, it is necessary to make an adjustment in one of the building sections of the documents. So, to lower the level of production of harmful and toxic particles, it is necessary to provide additional measures around the perimeter of the entire room.

Sanitary standards for designing industrial enterprises

According to the SNiP rules, any unfavorable elements such as moisture and heat released in the industrial premises are taken from the calculations of the technological part of the design documentation.

If such data are not available in the technological norms of design, the amount of industrial harmful substances emitted in the room may be accepted based on the natural facts of the study. The sought value is also indicated in the passport papers of the acquired specialized equipment.

Emissions of toxic substances into space occur through concentrated and dispersed devices of the general exchange ventilation system.

Calculation of emitted substances should provide for their amount not exceeding:

- The maximum value for the city and settlements.

- Indicators of the maximum amount in the air that penetrates into residential buildings through the windows according to the principle of natural ventilation (30% of the norm of the established limit for the concentration of harmful, toxic substances in the working area).

The determination of the dispersion coefficient into the working space of toxic elements present at the time of discharge in the system are part of the ventilating project of the enterprise. So, according to standards, in industrial premises, provided that the air volume per subject is 20 m3 it is necessary to take into account the process of supplying outdoor air. So in total, it should be up to 30 m3\ h for everyone in the subject’s premises. If, for one person, there are more than 20 m3, the amount of air supplied from the outside must be at least 20 m3\ h for each subject.

For a working area in which the air volume is more than 40 m3, subject to the location of ventilation windows and transoms and in the absence of toxic elements, the standards provide for a working (active) natural ventilation system.

When creating a project for a working zone for industrial production purposes, in which there is no natural ventilation, while with the supply of external air into them only by means of existing mechanical ventilation, the total amount of air should be at least 60 m3/ h per subject. The indicator can vary within the tabular data, but at the same time be at least one multiple airflow per hour.

If the calculated rate of air multiplicity is less than the tabulated one, and recirculation is used, the volume of the external flow can be less than 60 m3/ h for one subject, but not less than 15-20% of the total air exchange flow in the system.