Innovative sound-absorbing window panes and high-quality soundproof materials significantly reduce the amount of external noise in the premises. However, a significant proportion of the noise in the room can be generated by internal sources such as ventilation and air conditioning. The noise they produce, namely, the monotonous humming and howling air, although they do not irritate as much as the sounds of a disco in a nearby building, they gradually shake the nervous system and provoke insomnia and stress.

That is why the insulation of air ducts is considered one of the paramount tasks that need to be thought out and completed at the design stage.

Causes of ventilation noise

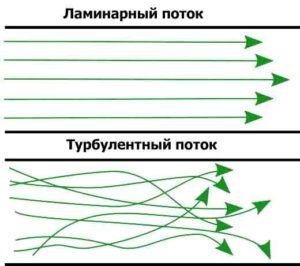

The main cause of ventilation noise is vibration due to turbulent air flows in the pipes. It occurs most often due to errors in the design of ventilation and incorrect acoustic calculation.

Even before the ventilation is installed, the developer must carefully study the house plan in order to find out in which rooms the acoustic noise should be minimal and in which insulation can not be installed.

Already on the basis of this calculation, the optimal installation location is selected, all the nuances of the ventilation system are calculated: materials, duct sizes, branching features, location of elbows and screeners. The type of ventilation equipment, as well as the method of insulation, is chosen at the very least, when all other nuances have already been taken into account.

Noises in ventilation pipes have a different nature, depending on which the following types can be distinguished:

- noise from the operation of equipment: convectors, pumps. It is transmitted directly with air flows, through the hood;

- vibrating noise from the water cooler and fan. It arises due to improper installation and insufficient rigidity of the walls of the air ducts;

- “Turbulent” noises that appear when branches, dampers, elbows, and other points of turbulence pass through air streams.

Sound insulation of air ducts with special materials can reduce or even completely eliminate all of the above types of noise.

Errors in the design of ventilation systems

The most common errors at the design stage, which entail an increase in acoustic noise, include:

- irrational installation of noisy ducts over rooms requiring a low noise level. Such noisy air ducts should be installed exclusively above the work and storage rooms, but if it is impossible to change their location, and they will be located above the living rooms, reception halls and bedrooms, then it is worth wrapping the pipes with insulating material, thickening their walls. In addition, in order to reduce noise due to turbulent air flows, it is worth installing oval or round ducts;

- use of recirculation air systems without special air pipes. Air in such a system should be directed through the duct, and not through the cavity of the false ceiling and ceilings. Otherwise, the noise from the air freely circulating through this cavity will be simply unbearable for residents;

- lack of vibration isolation of the duct. Measures for vibration isolation include, first of all, the installation of vibrating elements, which serve as a kind of counteraction to natural vibration in the system.In addition, it is worth remembering that all pipe connections adjacent to equipment elements must be flexible. Self-generated noise caused by turbulent air currents can be eliminated by installing large air ducts, during which air flow slows down. Turbulent flows can occur in any areas of ventilation, and the noise they create creates big problems for those who are in a ventilated room for a long time.

Features of sound insulation of ducts

The most popular sound insulation method is laying inside or outside the pipes of a special material (organic and fiberglass, rubber, polystyrene foam). In this case, the noise source is muffled, but its reason remains. As already mentioned, this problem should have been stopped at the root, that is, at the design stage. All soundproofing methods are capable of reducing the noise level in a functional environment to one degree or another, however, none of them eliminates the root causes of noise.

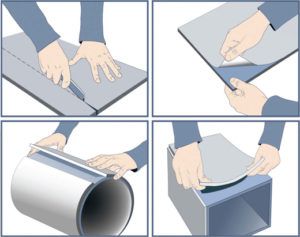

The best insulation performance for materials with a fleecy coating: mineral wool, organic fiber. Not so long ago, such a material as lamellar mats, notable for their transverse fibrillation, appeared on the construction market. This material is good, first of all, because it does not form creases on the bends, so that the material fits as tightly as possible to the pipe, and the noise level decreases by as much as 8-15 dB (the final soundproofing indicator varies depending on the degree of noise).

In order to choose a suitable insulating material in a particular case, it is worth considering the cross-section and shape of the pipes. Obviously, the highest degree of insulation can be obtained only when the entire surface of the ventilation system is uniformly coated with the insulator, which does not allow the appearance of “sound breaks” (places where there is no insulating coating). All seams and joints must be carefully sealed with tape, or pulled together with bandages.

To reduce the level of turbulent, uncontrolled noise, you can put a special absorption silencer.

Materials for insulation of ventilation ducts

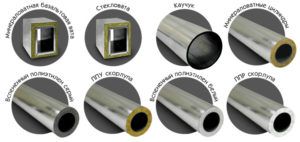

Thermal and sound insulation of air ducts is usually carried out using the following materials:

- mineral wool;

- extruded polystyrene foam;

- polyurethane foam insulation;

- foamed polyethylene.

The procedure for insulating air ducts with mineral wool includes the following steps:

- pipe cleaning from dirt;

- winding in one layer of mineral wool;

- overlay of a foil insulation with a thickness of 0.4 cm (so that the heat does not come out and the cold does not penetrate inside);

- sealing seams with aluminum tape.

Sound insulation of air ducts with polystyrene foam insulation provides the greatest durability of pipes and increases their resistance to corrosion. For the insulation procedure, you need to cut polystyrene foam into pieces of the right size with a knife, and put these half-cylinders on the pipe, displacing them by 20-25 cm, with a view to more tight shrinkage. Seams are closed using special puffs-bandages.

The installation of polyurethane foam and expanded polystyrene is no different from the installation of extruded polystyrene foam. The only difference between these materials is that they do not burn and are less thermally conductive than expanded polystyrene and mineral wool.

The leading frequency of installations in domestic conditions is occupied by such material as foamed polyethylene. The process of installing it is extremely simple: it all starts with measurement, then the polyethylene sheath is opened along the seam and fastened around the pipe, and at the end of the work, the joints and seams are sealed with glue or tape.

The general rule for all types of ventilation insulation is that the material must be of high quality, and the installation must be professional.Correctly selected insulation material and proper installation will save a significant amount on the repair of ventilation systems, as well as reduce the risk of accidents.