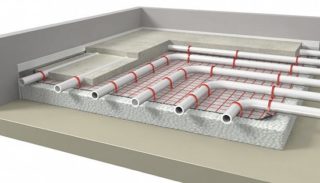

When installing a heating circuit located in a polystyrene floor, it is necessary to securely fix the pipeline and the floor heating cable on the base provided for them. For these purposes, various types of fasteners such as harpoons, mounting tape and similar devices are used. The most effective tool is considered an anchor bracket for a warm floor, used exclusively on hard substrates. Users should learn more about the original type of mount, as well as understand all the intricacies and features of its design. Many experts and amateurs are also interested in the selection of products suitable for the stated purposes.

Description of Anchor Brace

The fastening of pipes on the floor surface by means of special brackets is organized according to time-tested methods, which are based on a manual or semi-automatic principle. These methods are especially effective at bends or bends of thermal circuits with a significant length of the laid routes. On extended sections of the pipeline, the fixation points are located at a distance of about 50 cm from one another, and in the fracture zones this interval decreases to 10 cm. Compliance with the indicated step allows fastening the pipes qualitatively and reliably, significantly extending their service life.

Anchor brackets are made of a material characterized by increased strength and capable of withstanding significant overloads. The design of the fastener provides special spacers, thanks to which the teeth and clamps of the pipeline are fixed as reliably as possible. Upon completion of the installation of such products, it is almost impossible to release them without a foreign tool.

Specifications

Anchors in the category of fixing devices are classified by type size corresponding to the width of their base mount. This parameter is decisive when familiarizing yourself with their technical characteristics. According to the existing classification, they are divided into samples of the following type:

- U-shaped brackets of the STK brand, suitable for fastening tube blanks of various diameters;

- plastic anchor fasteners used for fixing pipes of the “Du 16” type in the “water floor heating” system;

- the same products designed for pipe size “Du 20”.

In the practice of installing underfloor heating systems, anchor brackets for a warm floor of 16 mm are especially common, optimally suitable for attaching to an insulating flooring board from expanded polystyrene. The dimensions of such a bracket in height are about 51 mm. It contains double hooks in its design, thanks to which the fixed pipe is securely fastened and does not jump out of the insulation material.

Anchor products are suitable for the installation of underfloor heating from such well-known manufacturers as Uponor, Rehau, KAN and others. The approximate consumption of U-shaped brackets of the STK brand is 2 pieces per linear meter. They are made in the form of red clips that contrast well with gray plastic pipes.

Advantages and disadvantages

The advantages of anchor brackets include:

- high speed and ease of installation of products in comparison with other methods;

- reliability of fastening of pipe billets;

- durability;

- relatively low cost.

The fastening element may be used to fix other types of pipelines that are not related to a warm floor. Due to the presence of protective plastic teeth, the products in question are highly resistant to shock loads. The disadvantages of fastenings of this class include the complexity of installation on some types of water and electric underfloor heating.

Installation technique

The most common use for anchor brackets is the fastening of underfloor heating elements with a frame size of 16 mm. Laying the structure with their help is organized according to the instructions prescribing the following sequence of operations on polystyrene plates:

- The floor base is cleaned of accumulations of dirt and dust, as well as debris remaining after construction work.

- The floor surface is carefully leveled, and too large differences in height are eliminated by means of a self-leveling mixture.

- After setting on a flat surface, a layer of plastic film is used as a waterproofing protection.

- Separate pieces of it are wound one under the other, and the places of overlap are then sealed with construction tape.

- The surface is laid with a typical edging tape, on top of which polystyrene mats are laid out with a slight offset.

- The latter are fastened together by means of special type locks.

- Directly on the surface of the polystyrene coating, the laying of the thermal circuit is made.

At the final stage of arranging a water heated floor, they proceed to fixing pipelines based on polypropylene on a previously prepared base. For this, anchor brackets already selected in size are used. At the end of this installation phase, the entire structure is closed on top with two layers of gypsum fiber blanks.

Automation of mounting anchor brackets

A method is widely spread among professionals, according to which a special device called a “tucker” is used to fix the pipes. The latter accommodates at least 120 anchor brackets installed in a semi-automatic mode. If you use the pre-applied marking of the installation sites, using this device, you can fix the pipe quickly and reliably.

The disadvantage of such devices is their high cost and the need for preliminary manning a set of staples. In the domestic market, branded products of this class are extremely rare. Most often, these devices are used by experienced craftsmen or professionals working in the construction industry.