Gas heating of the house requires strict adherence to the standards when installing the equipment. The chimney for a gas boiler is an integral element of the heating system. Not only quality heating work, but also the safety of residents depends on the correctness of its installation. It is necessary to understand the requirements and recommendations for the installation of gas equipment.

Why do you need a chimney for gas boilers

During combustion, a substance hazardous to human health is formed. The result of inhalation of carbon dioxide can be a sharp deterioration in general condition and even death. If the chimney for the boiler is installed with violations or is damaged, the chances of getting poisoning increase.

Carbon monoxide is insidious in that it does not have a pronounced smell and color, so poisoning occurs gradually. Carbon monoxide provokes oxygen starvation and negatively affects all biochemical processes in the body. To prevent tragedy, the installation of the chimney should be treated very carefully.

Materials for the manufacture

The chimney pipe can be made of different materials, but all of them must meet certain requirements - be airtight, fireproof and resistant to aggressive chemical environment.

Brick

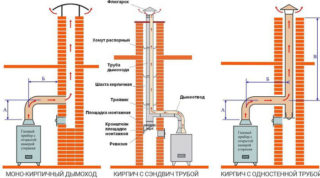

Installing a chimney pipe made of brick is not a new or even outdated method. It is not particularly popular primarily because of the massive structure, under which it is necessary to mount a separate foundation. This process requires a lot of effort, time and financial costs. In addition, only an experienced craftsman can perform high-quality masonry.

There are also technical disadvantages of this design. Non-smooth inner walls provoke soot accumulation, which subsequently leads to a decrease in traction. Another disadvantage is the hygroscopicity of the brick. The condensate formed on its surface is absorbed by the brick and becomes the cause of its rapid destruction.

To solve these problems, an asbestos or steel liner is mounted inside a brick pipe. It is necessary to consider the following:

- The liner at the joints should be tight. When installing an asbestos-cement pipe, coating the joints with cement mortar will not resolve the issue of condensate absorption. In this case, you will need to use hydrophobic chemically resistant compounds or make a connection using sealed clamps.

- Insulation of the pipe will reduce condensation. Thermal insulation material must have moisture resistant properties.

- To collect condensate and remove it from below to the pipe in an accessible place, mount a tank.

A brick chimney mounted in accordance with the above rules will not cause difficulties even with abundant condensation.

Stainless steel

The installation of a lightweight chimney for a gas boiler has been widely used in private houses of any size and number of storeys. Condensation is formed due to the high temperature at the outlet, which is typical for all modern heating boilers. If the draft is good, part of the moisture is removed into the pipe, and high-quality thermal insulation of the structure promotes evaporation of the remaining condensate. Therefore, it is often possible to observe the picture when the condensate tank remains empty, but this does not mean that condensate is not released.

The installation of a lightweight chimney for a gas boiler has been widely used in private houses of any size and number of storeys. Condensation is formed due to the high temperature at the outlet, which is typical for all modern heating boilers. If the draft is good, part of the moisture is removed into the pipe, and high-quality thermal insulation of the structure promotes evaporation of the remaining condensate. Therefore, it is often possible to observe the picture when the condensate tank remains empty, but this does not mean that condensate is not released.

Food grade stainless steel is a material with unique performance properties.It withstands prolonged exposure to aggressive chemicals. It differs from other varieties at a higher price, but its service life is higher.

The formation of condensate in a small amount and its rapid evaporation is facilitated by the uniform temperature of the pipe - it is important that it does not cool down. To do this, perform its insulation. An effective design for the installation of the chimney has a material of the type "sandwich" with insulation inside in the form of non-combustible basalt wool. However, it is recommended to insulate the area located on the street outside so as not to lose traction and extend the life of the chimney.

The advantage of a sandwich is a lower consumption of insulation than with a single-wall stainless steel structure. In this case, the outer material of the sandwich can be made of cheaper galvanized steel, which is not exposed to contact with condensate, high temperatures and has additional external insulation.

Primary requirements

Requirements for smoke channels are reflected in regulatory documents and are mandatory. Among them, the following can be noted:

- joints should be tight and moisture resistant;

- the lower part of the pipe should be equipped with a plastic or steel condensate collector;

- the height of the pipe should provide good traction, therefore, it should rise from the roof surface by at least 50 cm;

- a peak is mounted above the pipe, which will protect it from ingress of rain and debris.

These rules will guarantee the safe operation of the gas heating system.

The design and layout of the chimney

The combustion chamber is of two types - open and internal combustion. This factor determines the type of chimney. In the first case, an ordinary pipe is mounted, and in the second, a coaxial pipe.

The principle of operation of an open combustion chamber is that the flue gas is discharged through a pipe into the atmosphere due to draft, and oxygen for combustion enters the chamber from the room in which the boiler is installed.

For a boiler with a closed chamber, a coaxial chimney is mounted. It consists of two pipes inserted one into the other. One is used to supply air that supports the combustion process, and the second - to remove combustion products. On the street such a pipe is often led out through the wall, since the turbine provides traction.

Correct installation

Chimneys for gas boilers need proper installation and installation. To do this, follow certain recommendations.

Chimneys for gas boilers need proper installation and installation. To do this, follow certain recommendations.

Section selection

The chimney cannot have an inner diameter smaller than that of the outlet pipe on the boiler, through which the equipment and the pipe are connected. It is also worth considering that the curvature and narrowing of individual sections of the chimney are unacceptable throughout its length.

If you have to connect two boilers to one pipe, its cross section is increased. The size of the inner diameter of the pipe should be equal to the sum of the diameters of both nozzles.

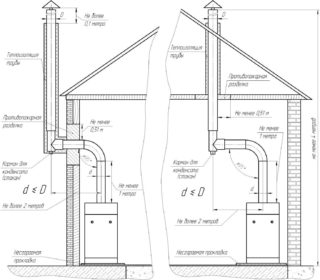

Slopes and indents

The location of the pipe should be vertical. When designing a chimney, it is better to avoid inclined sections. If this cannot be achieved, it is important to consider that the deviation from the vertical location should not exceed 30 °, and the cross section should remain within the standard values. The length of the section mounted with a slope should not exceed the height of the room.

There is a limited number of permissible turning sections - there should be three of them.

Connection Requirements

A tight connection during the installation of individual parts of the chimney is obtained through the use of special clamps. When installing pipes, material is taken into account for adjacent surfaces. If they are made even of hardly combustible raw materials, the distance to the chimney should be 25 cm or more. In this case, it is recommended to insulate the pipe from the outside with asbestos board or other fire-resistant material.If the material is fireproof, the distance can be reduced to 5-10 cm.

Particular attention is required to the joints of the chimney duct and fasteners - they use durable material that is resistant to mechanical stress. It is important to exclude the load on the areas located at an angle.

When assembling stainless steel pipes, the immersion depth of one element in another should be equal to the radius of the channel or be slightly larger. In this case, the formation of gaps is unacceptable. Otherwise, there will be a chance of carbon monoxide entering the room.

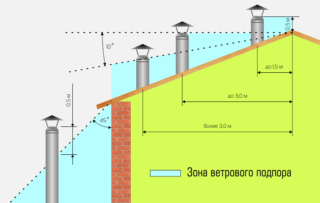

Roof Location

When choosing the location of the flue, it is taken into account that for a gas boiler the location of the channel above the roof at its highest point should be at least 50 cm. The distance from the chimney to the edge of the overhang should not exceed 150 cm.

If the protruding part of the chimney is removed from the ridge by a distance of more than three meters, its height may be less than 50 cm.

If the roof is flat, the height of the chimney should be 1 meter. If the roof structure is combined, the smoke channel above its surface should rise by 2 meters.

Inside and outside the pipe is insulated to prevent the formation of too much condensate. It will still appear, but inside the insulated pipe will evaporate. If there is an excess of condensate inside the channel, corrosion processes will begin to appear over time, which will lead to the destruction of the entire structure. Insufficiency of insulation also affects traction reduction.

Possible errors when choosing a flue

If during operation of the heating system an excessive amount of condensate is formed or there is not enough draft, most likely, the installation of the chimney was performed with violations. The most common errors during the installation of the chimney include:

- wrong choice of section and height of the channel;

- insufficient use of insulation on the outside of the pipe or on a section inside an unheated attic;

- violation of fire safety requirements.

The cause of malfunction and rapid destruction of the exhaust pipe may be the choice of the material that is not suitable for it. For example, it can be unstable to high temperatures, aggressive chemical environment or have insufficient wall thickness.