To create a comfortable temperature in the house, various heating schemes are used. Providing forced circulation of the coolant is effective, but not always possible. If in a country house there may be power outages or lack thereof (cottage) - the other option would be the best option. A self-designed gravity heating system of the closed type designed and installed by itself will perform its functions without installing a pump and other electrical equipment.

Features of gravity heating system

The principle of operation is based on the property of water to expand with increasing temperature. Creating a pressure difference in a closed pipe circuit is the basis of fluid circulation. Due to this effect, the gravitational closed heating system received another name - gravity.

Structurally, it should consist of the following elements:

- Boiler. A device designed to transfer the energy of burning fuel (firewood, coal, gas, etc.) to a coolant (water, antifreeze). In a gravitational closed heating system, this happens with the help of a heat exchanger located as close as possible in the boiler to the combustion chamber;

- Pipelines. Required for transporting heated fluid from the heat exchanger to the heating devices;

- Radiators. They are the main source of heat in the room. Their large area provides maximum heat transfer between heated water and air in the room;

- Safety and control devices. These include an expansion tank, a gravity valve for heating, valves and chokes.

During heating of water in the heat exchanger, it expands, which creates excess pressure. In turn, the cold coolant from the return pipe has a higher density and begins to displace the liquid with a high temperature. As a result of this, circulation occurs.

One of the main elements of the system is the booster manifold - a vertical pipe connected to the boiler. If you make a gravitational heating system with your own hands, you need to pay special attention to it - starting from the material for manufacturing the pipes and ending with their diameter.

The larger the volume of the booster manifold, the higher the coolant speed. To do this, you need to calculate its optimal section and height.

The gravity heating system of a two-story house should be designed so that the coolant can be distributed as evenly as possible across several circuits.

Detailed system description

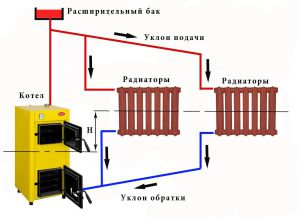

In the process of heating water, some of it will inevitably evaporate in the form of steam. For timely removal, an expansion tank is installed at the very top of the system. It performs 2 functions - through the upper hole, excess steam is removed and automatic compensation for the loss of liquid volume occurs. A similar scheme was called open.

However, it has one significant drawback - the relatively rapid evaporation of water. Therefore, for large branched systems, they prefer to make a gravitational heating system of a closed type with their own hands. The main differences of its scheme are as follows.

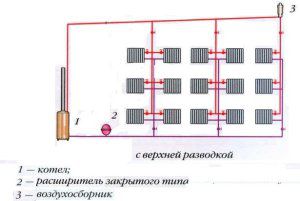

- Instead of an open expansion tank, an automatic air vent is installed at the highest point in the pipeline.A closed-type gravitational heating system generates a large amount of oxygen from water in the process of heating the coolant, which, in addition to excess pressure, is a source of rusting of metal elements. For the timely removal of steam with a high oxygen content, an automatic air vent is installed;

- To compensate for the pressure of the already cooled coolant, a closed-type membrane expansion tank is mounted in front of the boiler inlet manifold. If the gravitational pressure in the heating system exceeds the permissible norm, then the elastic membrane compensates for this by increasing the total volume.

Otherwise, when designing and installing a gravity heating system only with your own hands, you can follow the usual rules and recommendations.

Gravity heating schemes for a one-story and two-story house

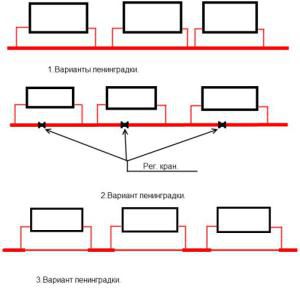

If it is planned that gravitational heating under pressure will be installed in a one-story house, you can apply the one-pipe Leningradka scheme.

A feature of this scheme is a single pipe to which several heating appliances are connected in parallel. However, this leads to an uneven distribution of heat - the farther the radiator from the boiler - the lower the temperature of the water entering it. To solve this problem, you can upgrade the gravity heating system of a closed type:

- Installation of shutoff valves. With its help, it is possible to reduce the volume of coolant for heating appliances located closer to the boiler. Thus, the thermal energy loss in the first sections of the system will decrease;

- When moving away from the boiler, increase the number of sections of radiators;

- Install pipes of larger diameter in the place where the pipes are connected to the heating devices. This will reduce the gravitational pressure of the heating system in this area, which will reduce the speed of water circulation in the radiator.

This scheme is acceptable with a small length of the highway. However, it is not recommended to install it for a two-story house. In this case, a two-pipe branched gravitational heating system is required, the calculation for which is carried out in individual sections.

Its feature is that separate circuits lead to the central pipe located in the upper part of the highway. Heating appliances are connected to each of them. It is important that their length is the same. Otherwise, all the liquid will rush to the region of least resistance - to a short circuit.

To prevent the coolant from moving to the boiler outlet pipe, a gravity check valve for heating is installed. This is an indispensable element for the gravitational heating system of a two-story house.

Calculation of gravity heating system

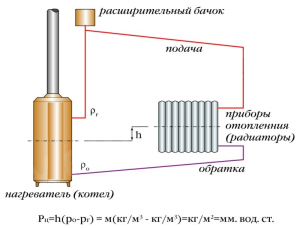

Before proceeding with the installation of pipes and heating devices, it is necessary to calculate the parameters of the entire system. For this, hydraulic characteristics are calculated, which subsequently affect the choice of the optimal diameter of the pipeline. Before calculating the gravitational heating system, it is necessary to find out the main parameters. They will be required to calculate the actual value of the circulation pressure (RC):

- Distance from the center of the boiler to the center of the heater (h). The larger it is, the better the fluid circulation will be. Therefore, installing a gravity heating system with your own hands, it is recommended to mount the boiler at the lowest point of the house - the basement;

- Circulation pressure of heated (Pr) and cooled (Po) coolant.

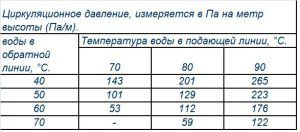

Regardless of whether the gravitational heating system is calculated for two-story or one-story houses, the value of the latter parameters directly depends on the difference in water temperature.This data can be taken from tabular data.

For example, with a value of h-4 m and a temperature difference of 20 ° (80/60), gravity heating will have a pressure of 4 * 112 = 448 Pa. For further calculations, it is recommended to use specialized software systems that take into account all the parameters of the gravity heating system of a closed type.

Often, the diameter of the pipe connected to the outlet of the boiler must be DN 40 or DN 50. This will ensure minimal losses that occur when the water is rubbed against the pipe walls.

Another feature is the temperature difference of the coolant. The larger it is, the higher the circulation pressure. Therefore, in addition to the uniform distribution of heat across the heating devices during the design of the gravitational heating system, it is necessary to independently ensure the minimum temperature of the liquid before entering the boiler heat exchanger.

Selection of components and material

After the advent of polymer pipes, the gravitational heating system made of polypropylene (PP) has become very popular. This material is easy to process; a minimum of equipment is required to connect individual sections.

However, not every type of these pipes is intended to be installed as a heating element. Consider the main selection criteria:

- The presence of a reinforcing layer. The gravitational heating system made of polypropylene can be affected by high temperatures - up to 95 ° C. To preserve the original shape of the pipe, a stiffening element is required, which is a layer of foil or fiberglass;

- Wall thickness. In a gravity heating system with a closed expansion tank, high pressure can be generated. To avoid damage to the line, polypropylene pipes must be of class PN20 or higher. The thickness of their walls depends on the diameter.

This pipe can be used to equip the booster manifold. However, in order to achieve a temperature difference, the return line is recommended to be made of steel. In addition to lowering the temperature of the coolant before entering the boiler, this material helps to reduce the hydraulic resistance.

Installation Recommendations

Having performed the calculation for a gravitational heating system made of polypropylene or steel pipes, you can begin to install it. To achieve optimal efficiency, experts recommend making small, but important changes to the standard scheme:

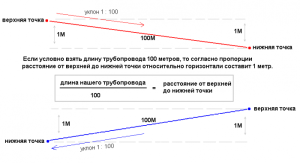

- Highway Slope. The optimal gravitational pressure for the heating system can be achieved by sloping the pipes after the air vent and on the return line behind the last heating device;

- Installing a circulation pump in the bypass. It will help to reduce the inertia of the system. The heating medium’s heating time can be very long, so the pump can increase its speed along the line until the desired temperature regime is reached;

- Minimum swivel nodes in the pipeline. They create excess hydraulic resistance, which affects the decrease in the speed of movement of water;

- Installation of protective elements. By installing a non-return valve for gravity heating, water can be circulated in the wrong direction. This is especially necessary for a system with top wiring and multiple circuits.

The main components of a properly made gravity heating under pressure are professionally made preliminary calculations, the selection of the right materials and following the installation technology. This will make it possible to create an effective system for maintaining a comfortable temperature in the house.

Tips for arranging and using the gravity valve for heating when installing a warm floor, additional elements can be seen in the video: