Constantly increasing heating and electricity tariffs are forcing people to look for new, more efficient and less costly ways to heat their homes. Water heated floor in the apartment is a design that is designed to create a comfortable and healthy atmosphere with little investment and sufficient security. It’s not difficult to make a water circuit yourself and connect it to the main system, but this procedure has a number of nuances, each of which is irreversibly taken into account.

Difficulties in the design of water heated floors in the apartment

In most of the country there is a moratorium on the installation of individual heating in apartment buildings. There are two reasons for this decision. The first is that the floor circuit takes a lot of coolant, which is not enough for residents of other floors. The second reason is a decrease in the profitability of heating systems during mass blackouts from centralized lines. Therefore, it is forbidden to independently connect to the common pipeline; a large fine is imposed for such actions.

It is possible to supply a gas boiler by yourself only in a private mansion after obtaining permission from the gas office. If you are lucky enough to disconnect from the central heating earlier, there are no barriers to dispose of the system at your discretion. The controllers are not interested in how the radiators and the circuit are located. They care only about safety and compliance with the rules of operation of heating equipment. But here one nuance should be taken into account: if the owner of the real estate decides to install an outdoor water circuit himself or with the help of specialists, all responsibility for the consequences of emergency situations will rest with him.

In the event of a rupture of the internal highways, several apartments from below may be flooded, and this is the millions of expenses for compensation. It is easier and safer to install an electric cable or film system.

Advantages and disadvantages

Like any design, a warm floor has its pros and cons. Before making a decision on installation, they need to be studied objectively in order to make the right decision in all respects.

Like any design, a warm floor has its pros and cons. Before making a decision on installation, they need to be studied objectively in order to make the right decision in all respects.

Advantages of the system:

- Even distribution of heated air. It rises up, creating a pleasant feeling of comfort and coziness.

- The optimal heat ratio for the body. When the legs are warm and the head is cold, the person feels well, experiencing pleasant sensations and not risking getting sick at the same time.

- If the system is designed for basic heating, there are no wall radiators. There is no problem with dust cleaning, periodic maintenance and replacement.

- Free up space that used to be allocated for strapping and batteries. More freedom for design and space for interior items.

- Almost zero chance of leaks. The contour is made of flexible polymer pipes with reinforced walls. All connections are on the surface, where they can be controlled, take timely preventive and maintenance measures.

- Low cost of operating costs. There is no need to pay for personnel services, coolant transportation, losses and taxes, as happens when connecting to city communications.

There are few negative sides, but they also need to be taken into account:

- Quite tangible initial investment.Even if you already have a boiler, you will have to spend a considerable amount on the purchase of materials, devices and work.

- Large volume of construction waste. As a rule, you need to dismantle the old screed, fill in a new one, and this is accompanied by the formation of fragments and dust.

- The duration of the arrangement. For a period of at least one month you can not live in the room. This is due to the fact that the full crystallization of the poured cement mortar takes 28 days.

The decision to install the water system must be balanced and thoughtful, not forgetting the seasonal factor.

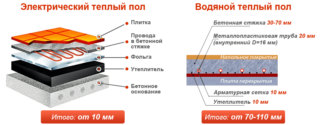

The difference between a water floor and an electric one

Outwardly, the circuits of the electric and water circuits practically do not differ. Regardless of the design (cable, mat, film), they are laid in a spiral or snake with a certain distance between the turns.

Outwardly, the circuits of the electric and water circuits practically do not differ. Regardless of the design (cable, mat, film), they are laid in a spiral or snake with a certain distance between the turns.

The differences between the systems are as follows:

- Source of energy. In one product it is electricity, and in another - natural gas. The cost of the latter is lower, based on which the volume of expenses varies.

- The environmental component. Water is neutral and enclosed in a sealed container. It is not dangerous even when additives are added. The cable generates harmful electromagnetic radiation.

- Life time. The cable does not exceed 15 years. Polymer pipes are designed for at least 50 years.

With the right choice of material and observing the installation technology, water systems compares favorably with electric ones.

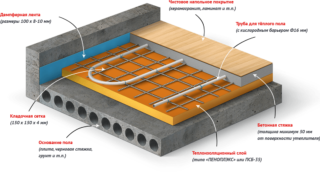

Common VTP device

A warm water floor has a rather complicated device, since it must heat the room with high quality and be safe in all respects.

The scheme includes such elements:

- Circuit. It is made of cross-linked polyethylene pipes. The presence of internal metal reinforcement gives products strength and constancy of shape.

- Thermal insulation. It is laid on the base to retain heat, which emits a circuit. Expanded polystyrene boards with a smooth or molded surface under the pipe are used.

- Gates They are made of non-ferrous metal, which is a sign of durability. Parts are installed at the inlet and outlet of the circuit to divert the forward and reverse flow. Designed for planned or emergency shut-off of water before inspection, during repair or an emergency.

- Three-way check valve. It provides the movement of water in a given direction, mixes cold and hot flows to achieve the optimum temperature in the circuit. At maximum and minimum values at the input and output, it varies within + 45-50 ̊С.

- Circulation pump. Designed to create pressure in the system and constant circulation of water through the system. The pump is selected based on the area of the room and the number of individual circuits laid on the floor. The most modern control systems involve the combination of a thermometer, sensors, a three-way valve and a pump in one unit. Automation provides more efficient operation of the structure, efficiency and prevention of emergency situations. The pump is equipped with a valve for bleeding air, which allows for a constant flow of fluid.

- Collector. The product is installed at the pipe exit point when several separate closed circuits are installed in a large room. The collector distributes the flows along the lines, through a three-way valve, maintaining the same pressure and fluid velocity in them. Due to this, there are no temperature differences in different places of the room. Collectors are made of copper, brass and stainless steel. Each material has its pros and cons, but equally successfully copes with the functions assigned to the products.

- Expansion tank. The product is used to prevent rupture of the circuit under the influence of excessive pressure.When heated, the water expands, the excess volume is squeezed into the tank, and when cooled, it is drained back into the system.

Installation can be carried out independently, but it is advisable to entrust this issue to specialists with extensive experience in this field.

Water heated floor in the apartment

Before making a water floor heating, it is necessary to draw up design documentation. Based on the diagrams and drawings, the calculation of the needs of building materials is carried out. If everything is clear with piece devices, then the length of the pipes must be calculated in relation to each room separately. In this case, it is advisable to take products with a margin, since practice is significantly different from theory.

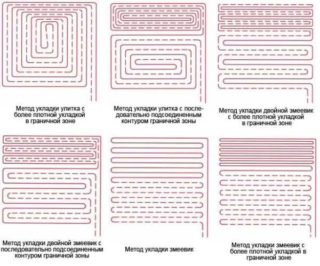

The need for pipes is determined by the selected layout.

The most common are:

- Spiral. The coolant is supplied from the center to the periphery or vice versa. A complex and not always effective scheme.

- Wave. The line is laid by a snake, where the same gap is left between the turns. Such a system is easier to install and more efficient in operation.

- Combined. They are used to equip large areas when a spiral is placed in the center, and along the perimeter of the snake.

The need for pipes is determined in their length by 1 m2. This determines the system power required for high-quality heating.

Depending on the step, this length is obtained:

- 10 cm - 10 l.m;

- 15 cm - 6.7 lm;

- 20 cm - 5.0 lm;

- 25 cm - 4.0 lm

- 30 cm - 3.4 lm

It should be borne in mind that the total length of the circuit cannot exceed 70 m.

When arranging the water floor, the pipes can be filled in with a screed, installed in molds or filled with heat-conducting bulk material, followed by covering with plates. In all cases, before closing, the circuit must be checked for leaks under pressure for 1.5-2 hours.