The system of external insulation of facades is a special design that protects the walls from the penetration of cold air flows. A wide segment of systems is presented on the market, each of which assumes compliance with certain installation rules.

Types of work

External insulation of the facade of an apartment building or private house is characterized by durability and a high level of heat storage. The inner lining is used if for some reason the implementation of the external type is impossible. The material used in the latter variety provides reliable protection against the cold. It provides the same temperature of the walls and rooms.

With internal insulation, moisture begins to collect in the area where the material and the wall join, which provokes the growth of mold. Over time, the wall can undergo destruction, because during severe frosts and the presence of condensation, it begins to freeze and expand.

Outside

The external method makes it possible:

- protect the room from external factors;

- protect from severe frost and moisture;

- isolate from noise;

- increase the duration of operation of the walls without repair work.

The main tasks that external insulation solves include:

- heat preservation in the room;

- savings on heating in the winter;

- improvement of sound insulation level;

- destruction of barriers during the evaporation of moisture;

External insulation is carried out after:

- waterproofing the foundation of the building;

- installation of all room systems;

- shrinkage of the base of the building;

- drying the building.

Insulation of the facade of the house outside is not carried out in extreme heat or frost. Typically, the lining is carried out in the autumn or spring. Concrete work should be carried out, as well as exterior decoration, screed, pouring, installation of alarm and electrical wiring.

Inside

The internal method is resorted to in the case of:

- being behind the wall of the apartment of the elevator shaft;

- the presence of a deformation seam between the houses, which is monitored by the meteorology service;

- assigning the building the status of a historical monument.

The main disadvantage of this type of insulation is the appearance of a dew point - a place in which steam from a room at certain temperature indicators turns into condensate. Dampness and mold growth can be avoided by using a vapor-proof material. The dew point remains inside, but moisture does not penetrate to it, the wall remains dry.

The negative point is the reduction in the area of the room. The thickness of mineral wool is 80 mm. To this indicator should be added the thickness of the air gap and drywall sheet. As a result, approximately 100 mm is lost. When using extruded polystyrene foam, the loss is less, since the thickness of the plate is 30-50 mm, and when finishing work, they resort to plaster.

The minuses can also include temporary eviction of residents from an apartment or house, as well as the destruction of walls due to periods of freezing and thawing. The last defect is eliminated when installing an additional ventilation system, which reduces the humidity indicator in the room.

When using the internal type of insulation, you can:

- align the walls;

- hide communications;

- provide sound insulation in the room;

- raise the temperature in an apartment or house;

- to carry out the installation of insulation materials with your own hands, which significantly reduces costs.

When placing the facade insulation inside, the installation process and the choice of material are very carefully approached. Expert advice is taken into account.

Materials for facade insulation

The market offers a wide range of different facade insulation for exterior decoration of the house. Each of them has certain qualities and is suitable for a particular type of building. Mineral wool, polystyrene foam and foam foam are used as insulation for a wet facade, which involves applying a layer of plaster.

When insulating facades, the following requirements are put forward for materials:

- optimal indicator of the level of thermal conductivity;

- high environmental friendliness, as the release of toxic substances negatively affects health;

- resistance to fire;

- duration of use;

- unchanged characteristics over a long operational period.

An additional advantage will be the optimal installation time and the minimum amount of construction waste.

Styrofoam

A non-flammable type of foam is used. To reduce the risk of fire, resort to the implementation of special notches made of mineral wool.

The material is not blown away by the wind, so installation of a protective film is not necessary. If there is a wooden frame for airing the material, a gap is left. With a frame made of steel, this condition is not mandatory.

Expanded polystyrene

According to its characteristics, the material is similar to polystyrene, but differs in a greater degree of density and reliability. It better protects walls from exposure to low temperatures. Many companies produce clinker tiles for the facade with insulation based on polystyrene foam. They imitate bricklaying. Such facade insulation is often used when facing private stone houses. Foam blocks have an attractive appearance.

Opinions of experts regarding the effectiveness of expanded polystyrene differ: some are rated positively, and others negatively. The latter opinion is based on the fact that the material has a low level of vapor transmission, as well as poor quality bonding with adhesives. The room insulated with polystyrene foam must be equipped with ventilation.

Plates gnaw through mice, so large slots and holes should not be present in the skin.

Having a closed structure, the material becomes impervious to vapor. Its installation is contraindicated for log cabins. Wood with the accumulation of condensate begins to collapse. Expanded polystyrene also does not insulate houses with a wooden frame.

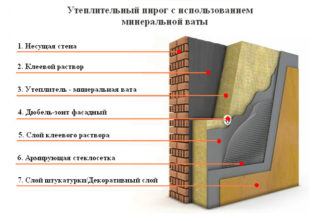

Mineral wool

Brick and wooden facades are usually insulated with mineral wool. The material does not allow streams of cold air and does not release heat from the room. Minvata is environmentally friendly, prevents the growth of mold. Its use is justified with the dry method of warming.

Mineral wool has a fibrous structure, has a high level of vapor permeability, is not flammable and is not subject to damage by rodents. It is suitable for warming all types of buildings, including frame and wooden structures.

For dry installation using mineral wool, a layer of air with a thickness of 20-40 mm should be made, which will provide a free flow of air throughout the skin.

Insulation thickness

The definition of this material parameter depends on the indicator of its coefficient of heat transfer through walls. The indicator is lower with a large thickness of thermal insulation.The degree of insulation is dependent on the thickness of the material and its thermal conductivity. Exceeding the thickness of insulation does not lead to an increase in thermal insulation.

There are materials on the market with three thickness markers:

- 50 cm;

- 100 cm

- 150 cm

The calculation is simple. The initial wall thickness and the assessment of an indicator that is not up to the norm are taken as the basis.

In addition to the thickness of the insulation, it is taken into account:

- layer of plaster;

- exterior finish;

- layer of air.

Each room has its own individual characteristics, therefore, when choosing a thermal conductivity marker, the heat capacity of the floor, the specifics of the basement and roof insulation, and the glazing area should be taken into account.

Methods of external insulation of the facade

Modern construction approaches suggest the following types of insulation of external walls:

- light plaster;

- heavy plaster;

- multilayer;

- siding.

Each type of installation has its pluses and minuses. Sometimes thermal insulation can be done with your own hands, but more often the help of an experienced specialist is required.

For plastering

The basis of insulation is a simple plaster structure. The option is popular. The main advantage is the use of safe and environmentally friendly materials. Also note the low cost of installation. The facade system includes many components.

The list includes:

- cement-based glue;

- Attractive finish

- heat insulation from the polymer-cement layer.

An indisputable minus is the impossibility of installation at low temperatures (below +5 degrees), as well as in the presence of precipitation.

Self-installation is not possible, since the plaster needs an absolutely even and dense application. Experience and practice are required.

Dry method

The dry method of warming is to conduct the outer skin of the premises with a structural frame. In the intervals between the elements is a heater that does not impede the penetration of steam. The insulation is covered by a diffuse membrane, which serves as protection from the wind. The frame is trimmed with finishing material. This is a heater for a ventilated facade: an air layer is left between it and the skin.

With the help of the frame, the unevenness of the walls is hidden, there is no need to clean them. Warming is carried out regardless of the ambient temperature conditions. Installation is carried out in stages, which is not possible with wet technology.

A dry system of external thermal insulation of a room does not require qualifications and the use of expensive tools. A person with the skill of handling carpentry tools can conduct insulation with their own hands.

The dry method is divided into light and heavy.

The first method involves the use of finishing materials, which are inherent in light weight. Large panels or boards are used. They are attached to the frame by means of hardware. They are screwed or nailed. Easy way suitable for any type of building.

The second method involves the use of heavy finishing materials made of stone or granite. High demands are placed on the strength level of the building: it must withstand the heavy weight of the plates.

Layered method

Through a heavy method, aesthetic, durable facades are created. The high price category explains their use in construction with a large budget. Heavy plaster boards are mounted on the wall using special brackets.

The system is a structure with several layers:

- heat insulating;

- reinforcing bars;

- plastering.

The thickness after the thermal insulation layer is 50 mm.The technology is similar to applying a wet facade. The difference lies in the consumption of material, since the layer of plaster has a greater thickness. A thick reinforcing galvanized wire mesh and anchor are also used to strengthen the slab to the wall.

Heavy plaster systems are strong and durable. The life of such devices is approximately 50 years. Glue is not applied during the work. The material is fastened with dowels, which preserves the integrity of the plaster layer during the settlement of the house, since the insulation is inherent in mobility with respect to the base.

A multi-layer system is applicable for the first floors. Installation requires high qualifications.

Under siding

Siding insulation is a fairly common method. Siding is a material that includes a set of panels of various colors and shades.

Panels can be:

- metal;

- wooden;

- vinyl;

- cement.

Insulation is placed between the bars of a wooden crate. The plate is fixed using special dowels or with glue. After this, the barrier layer is fixed. Siding panels are screwed to the frame base with self-tapping screws.

Well-known material manufacturers

The most popular brands that produce insulation include:

- Russian company "Technonikol". It produces insulation for a facade equipped with ventilation. Among them should be noted the line of "Prof", "Optima", "Standard" and "Technovent". The latest model consists of two layers. Technical characteristics of the products of this manufacturer are suitable for thermal insulation of walls with a high level of convection of air flows.

- Danish company "Rockwool". It launches a series of Batts facades from basalt fiber. The material is used in suspended structures with ventilation.

- The Finnish company Paroc, producing mineral wool brands WAB and WAS. The material has a high degree of strength and rigidity. It is used in single-layer and two-layer facade structures with a clearance for ventilation. The cost of the material is high, but justified by its excellent quality and reliability.

- Russian company ZAO Izorok. It produces slabs for insulation of the facades "Isovent", "Izolayt", "Izolayt-L". The material is notable for vapor permeability, as well as low thermal conductivity.

- French concern Saint-Gobain. It produces mats for insulation of the Izover brand KT-11, TWIN and KL-E. They differ from the miniplates in lower weight, which does not exclude installation on light facades, not designed for heavy loads.

- A subsidiary of the Spanish concern Uralita, the company Ursa. At the market is a facade insulation “Ursa Geo Facade”. The outer side of the material consists of fiberglass. Due to this, no additional installation of a layer protecting from the wind is required. Products have a low rate of heat conductivity, high adhesion, are resistant to chemical solvents, but when ignited, they begin to release toxic substances. For this reason, they are not shown for installation in industrial enterprises. Materials have a low coefficient of heat conductivity, high adhesion, resistance to various chemical solvents, but toxic substances are released during combustion. For this reason, they are not recommended for thermal insulation of industrial facilities.

External insulation of the facade walls is a necessary measure. Panel mounting is a practical solution. The procedure is carried out in accordance with detailed instructions. You should choose the right material and seek help from a specialist.