Gas cylinder heating in a private house is in demand in places where it is not possible to connect to the central gas pipeline or there is an unstable supply of electricity to install electrical equipment.

Arrangement of heating in a private house with gas from cylinders

Russia is an incredibly large state, in which there are many more settlements located far from the benefits of civilization and the main roads. To simplify life, people install a gas boiler from a cylinder.

There are no prohibitions or restrictions on an autonomous gas heating system for bottled gas. But there is a significant drawback - a large amount of fuel is required to heat a room, since it differs from gas from the central highway.

Heating the living space with liquefied gas is advisable in the following cases:

- minimal heat loss;

- building area up to 100 sq.m .;

- effective thermal insulation of the structure.

Heating with bottled gas can be considered as a temporary solution to the problem, since in the future it is possible to upgrade an existing boiler for supplying from a central gas pipeline.

The heating of a private house with liquefied gas is carried out using standard cylinders with a capacity of 50 liters.

Space heating is carried out by combinations of the following combustible substances:

- SPBTZ - winter version of the mixture;

- SPBTL is a summer option.

In winter, cylinders require constant monitoring. Even at abnormally low temperatures, gas mixtures do not freeze, but interruptions with their entry into the boiler are possible. To reduce the likelihood of breakdowns, it is recommended to organize the heating of the ducts with pipes on the principle of underfloor heating in the winter period.

Which boiler to use

Gas heating of country houses from cylinders is carried out using a heat generator for a boiler with a water circuit. You can use any modifications and models of heating boilers that are designed to burn natural gas. For its optimal functioning it is enough to replace the burner or replace / adjust nozzles. Many manufacturers include a special kit for liquefied gases.

Similarly, choose the device and its power. However, taking into account the large operating costs for gas heating, it is necessary to purchase a boiler with a high efficiency, for example, a gas condensing heat generator.

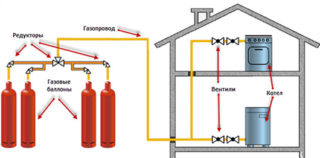

Connection diagram for the boiler

If cylinders will be installed at home, the system must additionally be equipped with the following details:

- shutoff valves;

- boiler;

- ramp;

- special nozzles for gas, if they do not come with the boiler;

- gearbox.

It is not recommended to install cylinders in the basement or basement; the most optimal place for them is a specially made metal box, with ventilation openings on the top and bottom of the front part.

Full cylinders must be stored strictly in a horizontal position, vertical is unacceptable. Install a metal box on the north side of the building in the most shaded place. For optimal operation of the heat exchanger, you need to connect it to 4-5 cylinders for heating. Before connecting them, you first need to familiarize yourself with all the features of the installation.

To install the outlet gas pipeline, pipes must be used with a wall thickness of at least 2 mm. A sleeve with a diameter exceeding the diameter of the pipe by 15-25 mm is mounted in the wall at the place of its passage. The interval between the pipe and the circumference of the sleeve is filled with foam.

The common reducer is connected simultaneously to several cylinders using a ramp - a two-arm collector that separates them into the main and spare ligaments.

The system can be equipped with gas holders, this is done using a reducer that returns gas from the liquid to a vapor state, for its secondary supply to the boiler. However, such an installation will require large financial costs.

During installation, all connections are made using hoses and pipes, their tightness is checked by washing the joints.

Gear Characteristics

Cylinder pressure is a variable that depends on a number of conditions. For instance:

- distance from the box with cylinders to the boiler;

- number of cylinders;

- temperature and composition of the gas mixture;

- fuel remaining.

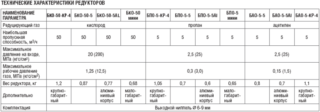

A reducer is a part designed to maintain and transform pressure in a stable state.

Choose a suitable gearbox according to two characteristics:

- operating pressure;

- performance.

The energy efficiency of the heating system at home with gas cylinders depends largely on fuel consumption. The productivity of the gearbox must not be less than the throttle response of the boiler.

The device according to the value of the working pressure is selected in accordance with the parameters of the heater. If the pressure in the gearbox is too high, the boiler automation may fail or the burner will simply go out.

Gearboxes have different modifications, are available with pressure parameters of 30, 37, 42 and 50 mbar. There are models in which it is possible to adjust this parameter between 20 and 60 mbar.

When connecting cylinders using flexible hoses, you will need a gearbox equipped with a “Christmas tree” fitting; when connecting using rigid pipes and combs, you will need fittings with threaded outlets.

Automatic gearboxes are equipped with protective elements. If the system pressure reaches critical levels, the automatics trips and opens the relief valve.

The cost of heating a house with gas cylinders

If the area of the house is about 100 sq.m., the boiler power must be at least 10 kW. To obtain 1 kW of heat, about 100-120 g / min of fuel will be required at 100% boiler load. If, for example, the duration of cold weather in a year reaches 7 months, approximately 5 tons of liquefied gas will be required for the entire season.

In practice, the flow rate is somewhat less, since during warming, the automation puts the system in an economical mode. If we compare the costs with the main pipeline, they will be approximately 5-6 times higher. But it is much cheaper than heating the room with electricity.

Fuel consumption can be reduced by the following rules:

- set automation;

- purchase fuel from regular and trusted suppliers, the gas composition must be excellent;

- mount propane sensors in a room with cylinders, which will immediately detect leaks;

- it is necessary to observe the optimum temperature regime.

If you follow these simple recommendations, gas consumption can be reduced by about 20-40%.