The installation technology of the underfloor heating system in a private house or apartment requires preliminary thermal insulation of the base. To maintain a comfortable room temperature with minimal heating costs, the use of foil materials is recommended. The metal layer reflects infrared radiation, reducing its loss by 3-10%. Such a substrate is indispensable when installing an electric floor heating.

The main characteristics of the material

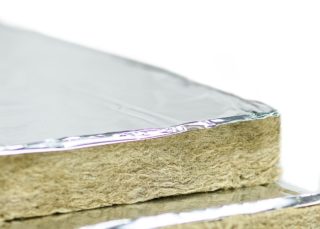

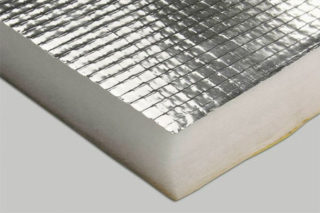

The foil backing is a multilayer material. The base of the insulation may be mineral wool, polystyrene foam or foamed polyethylene or polypropylene. The base layer provides heat and sound insulation properties of the material. Foil for underfloor heating serves as a reflector of infrared waves. The metallized surface reduces heat loss and prevents the penetration of water vapor.

The main characteristics of the substrate with foil:

- reflectivity;

- moisture resistance;

- elasticity;

- durability;

- excellent vapor barrier properties;

- light weight;

- sound insulation.

The effectiveness of reflective insulation depends on the thickness of the aluminum layer. Spraying 12-15 microns transmits radiation, not fulfilling its function. High-quality foil should be applied with a layer of 30-50 microns.

Another significant criterion is the thickness of the insulation. There are materials from 2 to 10 mm. At this height, the floor level in the room will rise. To save space, choose a substrate of no more than 5 mm.

The need for foil backing

Experts in laying warm floor systems unanimously confirm the need for laying the substrate. A heat-insulating layer prevents energy loss through a layer of concrete screed. Low coefficient of thermal conductivity provides the structure of the material. Closed cells of synthetic cloths filled with air and randomly laid mineral wool fibers are reliable heat insulators.

Foil for underfloor heating is used as reflective insulation. The metallized layer promotes uniform heating of the room. A significant area of the coating, directing infrared radiation into the room, allows you to save up to 97% of energy. Using a substrate reduces heating time and heating costs. The function of the material is also to protect the heating elements from moisture entering through the base.

When choosing a substrate, take into account the variety of underfloor heating and finish flooring. For the water floor system, a rigid insulation is selected that can withstand high loads. The aggressiveness of the concrete screed with which the pipes are poured should be considered. The substrate must have a protective coating. The option with a heating resistive or self-regulating cable can be laid under the adhesive solution, which does not harm the aluminum film. For such a system, a foil under-floor substrate is the best choice.

One of the varieties of electric floor heating are heating mats. These are wires laid according to the scheme and fixed on the basis of fiberglass. A substrate with an aluminum reflective surface is also effective for them. Film infrared mats laid under a laminate, parquet or carpet can overheat the foil, causing a short circuit. For IR film, a metallic lavsan coated substrate is recommended.

Features of substrates for underfloor heating

The technical characteristics of the substrate depend on the type of base layer:

- Mineral wool. Insulation is sold in the form of hard plates or mats. Its advantages: fire safety and low thermal conductivity. Thickness is from 20 to 100 mm. A significant disadvantage of mineral wool is the phenolic compounds used for bonding fibers. When heated, harmful substances are released. The substrate is not suitable for a water floor, with a small leak it loses its insulating properties. Popular brands with a minimum content of organic binders: Rockwool, Paroc, Izover.

- Extruded polystyrene foam with a layer of foil. The substrate is available in the form of mats of small thickness (about 20 mm). It has chemical and biological resistance, serves as additional waterproofing. The material is designed for temperatures from -180 to + 180 ° C.

- Foamed polyethylene - insulation is characterized by minimal heat and vapor permeability. To improve properties, it is laminated with foil. Elastic elastic material smooths out unevenness of the base. It is environmentally friendly, designed for long-term operation.

Substrates vary significantly in price. The most affordable are mineral wool and foamed polyethylene. Expensive options include multifoil and folgizolone.

DIY foil styling technology

Work with rolled reflective insulation is available for the home foreman. Installation of the material does not require special tools and knowledge. Required:

- roulette;

- scissors;

- aluminum tape.

The laying process begins after leveling and waterproofing the base. Cracks and grooves in the concrete screed are coated with mortar. Bitumen mastic or liquid glass is used as a moisture insulator. To fix the substrate will require special glue.

Mount on a wooden floor immediately after cleaning the coating. The best option is to buy material on a self-adhesive basis. If there is no sticky layer, then use double-sided tape. The material is cut across the area of the room. Separate parts are joined without overlap, placed right next to the walls. Cloths are laid with a heat-reflecting coating up. The seams between the strips are closed with metallic tape. The procedure ensures the integrity of the overall coating. The underfloor heating system is installed on the substrate. After checking it, the finish flooring is laid.

Popular brands of foil backings

The most popular products are those based on foamed polymers.

Folgizolone

The IZOLON trademark offers thermal insulation from foamed polyethylene. The material has a closed cellular structure. By applying a layer of foil or metallized film, the insulation reflects up to 97% of infrared waves. Two types of material are available:

- Cross-linked polyethylene foam - the fabric has excellent thermal insulation characteristics and a long service life.

- Non-crosslinked polyethylene foam - the product is inferior in strength to its analogue, but costs less.

The thermal conductivity of foil isol is 0.036 W / (m * K), working temperature is up to 100 ° C, water absorption is less than 1%. Warming on the floor with folgizolone gives a high-quality substrate that is not afraid of moisture and dynamic loads. Products are manufactured in rolls 1 m wide, 25 and 50 m long. Installation of steam and sound insulation is not required.

Ecofol

Soft and elastic insulation is made of foamed polyethylene, duplicated by a layer of metallized film. There are two types of product:

- Ecofol A - heat insulator with a layer of metallized lavsan film;

- Ecofol C - the canvas is covered with foil on one side and a self-adhesive layer on the other.

The material is suitable for all underfloor heating systems.According to the insulating characteristics, it replaces 15 cm of brickwork or 45 mm of wood. Ecofol is resistant to moisture and aggressive environment. The thickness of the web is from 2 to 10 mm. One of the advantages of the product is that it comes with ready-made markings for laying heating elements.

Penofol

Inexpensive and reliable heat insulator for the floor consists of several layers. Its basis is closed-cell foamed polyethylene. Reflective properties of the material are imparted by foil coating. The metallized layer is located on one or two sides. The aluminum coating has a thickness of 13-30 microns, and the blade is 2-40 mm. Due to its low vapor permeability, Penofol prevents the penetration of moisture under the substrate. The material is environmentally friendly, does not rot, weakly supports combustion. Light weight simplifies transportation and installation.

Multifoil

Uponor produces a multi-layer product with reflective properties. It serves not only for thermal insulation, but also has sound and waterproofing characteristics. The base layer of the multifoil for underfloor heating is polyethylene with closed air-filled cells filled with air. The surface of the insulation is covered with a foil of a smooth or embossed structure. Roll width 100 cm, dyne 60 m, thickness 4 mm. Markings are applied on the metallized layer in increments of 50 × 50 mm.

Penoterm

The products of the Russian brand are suitable as a substrate for electric and water heat-insulated floors. It consists of a foamed polymer and a metallized lavsan film. The material performs the function of insulation and sound insulation. The penotrem is easily cut and mounted. Its surface reflects 80% of infrared radiation. Thermal conductivity of the material 0, 034, operating temperature from -40 to 150 ° C.

A substrate with a foil layer is an essential part of the underfloor heating system. Its use increases the overall heating efficiency, reduces energy losses.