During the construction or repair of a building, you often have to figure out which insulation is better: polystyrene foam or mineral wool. Many experts believe that EPS or extruded polystyrene is optimal for thermal insulation, others prefer to choose mineral wool. Each of the insulators has its own thermal conductivity coefficients, characteristic parameters and differences. It is important to consider the operating conditions during selection.

The differences between mineral wool and polystyrene

It is necessary to select polystyrene foam or standard mineral wool taking into account the requirements and technological criteria of the building that needs to be insulated. Mineral wool refers to a number of roll insulation, foam is produced in the form of convenient plates. The most important parameter is the coefficient of thermal conductivity: for mineral wool, it is 0.039 W, for polystyrene 0.038 W. Despite the slight difference, the thermal capacity of each material varies significantly, because of this, the foam is more suitable for insulation from the outside, mineral wool is ideal for indoor installation.

Material safety is of great importance, this indicator can be determined by the level of vapor barrier. The foam has a dense structure and almost does not allow water to pass through, for this reason the convection process between the surface and the heater does not start. Condensation builds up inside, causing the walls to collapse if the dew point is displaced. Mineral wool is characterized by a higher level of convection and good air permeability, this eliminates moisture stagnation inside the insulated surfaces.

During installation, the foam has more advantages, since its boards are very tight against each other. If you additionally putty the seams, a layer of monolith is created, which prevents the penetration of cold air. Mineral wool is able to lose shape, for this reason, the areas in the places for connecting the elements are disconnected, losing heat. All mineral wool boards are laid as tightly as possible towards each other and are well fixed.

Mineral wool is not lit and is not able to cause a fire. The foam melts well and can ignite on its own, although it contains flame retardants that prevent the spread of fire. This factor must be taken into account during installation.

Analysis of material features

Before deciding on a choice between mineral wool or standard polystyrene foam, strength and resistance to various biological influences, moisture absorption and thermal conductivity coefficients, weight and ease of installation, and duration of operation are taken into account. In addition to these items, safety and environmental friendliness of the material, good thermal insulation and sound insulation are of great importance. Each of the materials has its own characteristic features.

Expanded polystyrene

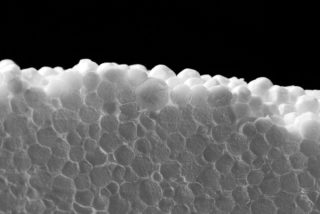

Expanded polystyrene is a plate filled with a large number of balls with air. Inside the structure of the material, there are no processes of circulation and movement of the air mass, so it is a good heat insulator for facades and floors. The list of its advantages include noise reduction, long life in high humidity and low temperatures. Polyfoam weighs a little, installs without problems and is not exposed to rodents or insects.Among its shortcomings note the ability to produce harmful substances during heating and the risk of fire in case of fire.

Mineral wool

Mineral wool provides optimal sound insulation, has a reduced coefficient in terms of thermal conductivity, is able to perfectly store heat and at the same time allow air to pass through. Such material is absolutely not subject to fire and can withstand temperatures up to 950 degrees. It has good thermal insulation and vapor permeability. In the mineral wool, rodents and insects do not start, and fungus does not form inside the plates. She has some disadvantages: high cost, high weight, the presence in the composition of components that can cause allergies during contact.

To choose a suitable insulation for the house, take into account the type of room that needs to be insulated. Both materials are well suited for buildings made of brick, aerated concrete or wood, houses built using the technique of frame construction or made of sandwich panels. Those who are limited in funds, it is better to choose a foam. But when it comes to building a warehouse for combustible materials, it is worth giving preference to mineral wool.

Composition and cost

To find out what is better: mineral wool or polystyrene foam, information on the composition and basic qualities will help.

The foam is based on urea, epoxy and phenolic resins, which increase when heated during production and turn into polystyrene granules. Finished boards mainly consist of 90% air and have different thicknesses, which greatly simplifies installation. The main advantage of polystyrene is low cost, this is a good budget option for those who are looking for high-quality and simple insulation.

Mineral wool is a material of fine fibers, which is obtained by melting rocks, a number of mixtures and metallurgical slag. Due to this content, the resulting product is characterized by durability, a high level of quality and excellent performance. Since silicate molten pieces from magma rocks are used during the production of mineral wool, it does not change shape at high temperature when it begins to warm. Due to the large number of positive properties, the price of this material will be much higher when compared with polystyrene foam.

The price of each of the materials depends on the manufacturer. The best choice will be products from trusted brands, manufactured using the correct technology without violating the instructions.

What is better to insulate with foam

Polyfoam is not suitable for internal insulation, as it is not able to convect air and has low vapor permeability. This can lead to the fact that the heat ceases to flow to the desired surface, and the dew point moves inside the structure. This is the best and most budget option for outdoor insulation. Scope of application:

- roofing and attic structures;

- foundations, especially of tape type;

- loggias and balconies;

- industrial and agricultural premises;

- cooling units.

If you need to work with uneven walls and in the absence of space for the crate, it is worth choosing polyurethane foam. In terms of properties, it is not inferior to polystyrene foam and also does not cause difficulties during installation.

What is better to insulate with mineral wool

It is advisable to use mineral wool in those cases when the foam cannot be used.It is chosen for warming houses and structures made of wood, since polystyrene cannot pass air and moisture, causing damage to the structure. Minvata most effectively works in rooms exposed to high temperatures. When it is necessary to insulate warehouses or structures for storing flammable or combustible substances, mineral wool insulation will be an excellent choice. Also, the material is suitable for those who want to create good sound insulation in addition to thermal insulation in the room. She practically does not miss sounds thanks to the composition and dense texture.

The best manufacturers on the market

When choosing a heater, you should pay attention to materials from leading brands. Among the manufacturers of mineral wool, Rockwool and Knauf stand out. The Danish brand Rockwool is a major mineral wool company. Buyers note the complete absence of shedding and shrinkage, the ability to choose from a large number of sizes and packaging options. Rockwool mineral wool is considered the most environmentally friendly, it absorbs noise well, has a high level of fire safety, and is able to keep its properties at the right level for a long time. Knauf produces mineral wool based on basalt fibers and distributes the products in series depending on the purpose. Among the available options are products for roofs, roofs, balconies and entrance doors.

The best manufacturers of expanded polystyrene and polystyrene are considered to be TekhnoNikol and URSA. URSA brand products are in great demand in Europe. The manufacturer has a base for extruding material that is created using innovative technology. TekhnoNikol operates in Russia and produces heaters that can compete with European counterparts. Each company’s plant has a separate research laboratory, where new production technologies are created and previous ones are improved.

When choosing a manufacturer, it is worth giving preference to brands that have a good reputation in the market.