The warming process at home is given great attention. Thanks to high-quality thermal insulation, a comfortable temperature will last longer, and less time will be required for heating. In a house, bathhouse, garage or other residential and non-residential premises, not only walls are insulated, but also the floor with a roof. Thermal insulation of the roof is one of the most difficult stages, so it is important to follow the instructions and follow all installation recommendations.

Roof structure

You can insulate different buildings. This can be a residential apartment building, a private cottage, an attic, a bathhouse, a garage, a barn. The process occurs in a similar way, and the laying pattern remains unchanged regardless of the purpose of the structure.

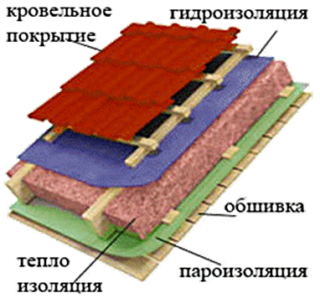

When warming the roof, the entire roofing system will consist of several layers. All of them are stacked on the rafters.

Layers are placed as follows:

- roofing;

- crate of the final material;

- counter bars;

- waterproofing;

- thermal insulation;

- vapor barrier;

- lathing for internal lining;

- interior decoration material.

A properly equipped roof will keep the house warm and reduce losses. Insulate the roof of the house from the inside so that there is no condensation, steam and waterproofing will help.

Choice of insulation

The range of insulation on the market is extensive, so it is difficult for an ordinary buyer to immediately choose the right material. To navigate and find the best option for a thermal insulator, you need to pay attention to its characteristics.

Insulation for walls, roofs and floors must meet the following requirements:

- Weight. The higher it is, the greater the load on the roof is provided by the insulation. Because of this, conditions are imposed on the rafters and crate.

- Thermal conductivity. It should be low, not more than 0.04 W / m * s.

- Resistance to external influences: vibration, shock, precipitation, condensation, temperature changes, humidity.

- Operating temperature range. For pitched roofs, the maximum temperature can reach 200 ° C.

All of the above characteristics correspond to several materials. Professionals prefer mineral wool and foam panels. Insulation is selected according to its properties and estimates laid down in the home improvement.

The best insulation for the roof:

- Usually, roof insulation is insulated with mineral wool. It is made in fiberglass, slag and stone forms. Sold in the form of mats, rolls and “plates in a roll” with different sizes. Pluses - plasticity, the ability to cut with a knife and good damping of sounds. It is necessary to use personal protective equipment at work. For a flat roof, mineral wool with a density of 150 kg / m3 is selected.

- The most affordable roofing insulation is foam. It retains heat well and is easy to style, light in weight. It has high soundproofing properties.

- Expanded clay differs in low cost. It is a small pebbles of different sizes, partially filled with air. Resistant to rodents, insects, steam and moisture.

- Ecowool is an ecological material, which is a cellulose web. It is easy to blow into a narrow space.

- Polyurethane foam is one of the most effective heaters. It is sprayed in the form of white foam. Does not pass steam.

- Extruded polystyrene foam has a clear geometry, high strength and good insulation performance.It has a long service life, moisture resistant, does not respond to chemical attack.

Popular manufacturers are Penoplex, Rockwool, TechnoNickel, Knauf, Izover and others. You can buy materials from these brands in construction stores.

In addition to the heat-insulating material itself, steam and waterproofing is required. To protect against moisture, it is better to use roofing material and polyethylene. As a vapor barrier, special membranes, glassine and foil materials are used.

Recommendations for work

Regardless of the insulation chosen, the master must carry out installation in a certain sequence. There are several recommendations that will make the internal insulation of the roof better.

Tips for the work:

- During installation, it is important to ensure that the plates do not block the ventilation openings.

- If a superdiffusion membrane is used, it is necessary to lay a heat insulator close to it.

- For a multilayer pie structure, two gaps should be made - under the film and above it.

- When laying thermal insulation in several layers, adjacent ones are staggered. This will make the insulation more reliable and close the joints.

- With a total thickness of the insulation layer of 20 cm, 2 layers of 100 mm should be put. Increasing the amount to 4 is not recommended.

- In order to lay the insulation as tight as possible, you should take a heat insulator with a width of several centimeters more than the distance between the elements of the rafter system.

- Plates should be applied to each other as tightly as possible.

- If the elements of the rafter system are located far from each other, the insulation is additionally fixed from the side of the room. For fastening, self-tapping screws are used, which are screwed into the rafter parts. A wire is pulled between them for fixation.

- When installing rafters with a small step, thermal insulation is used according to the combined method. Material is laid under and between the beams.

- If mineral wool is selected as the insulation material, it is necessary to make waterproofing. The film must be laid with an overlap and stick all the joints with tape.

- Plates between the rafters are laid evenly, without deflection.

Compliance with all of these recommendations will make it possible to make high-quality thermal insulation of the roof.

Heat insulation preparation

The order of roof insulation is practically unchanged for different types of roofs, used insulation and other factors. Before carrying out work, prepare a roof for internal insulation.

First you need to conduct a visual inspection of the rafter system. All broken or decayed elements must be replaced, otherwise the heat insulator cannot be fixed.

All wooden parts should be treated with a special antiseptic coating.

The last step is to check the condition of pipelines and electrical wiring, which are located under the roof. Defective parts should be replaced.

Only after a complete check of the suitability of the roof can one proceed with internal thermal insulation.

Roof insulation algorithm

The process of thermal insulation of the roof takes place in several stages. Rafters, lathing and other components should be installed in advance. The user only needs to fix the insulation for the roof and make the final roofing.

Do-it-yourself roof warming algorithm:

- vapor barrier installation;

- insulation laying;

- waterproofing installation;

- roof finishing.

The first step of insulation is the installation of a vapor barrier. It can be placed on top of the crate or under it. In both cases, it will perform its functions. The film should be laid with a 10-centimeter overlap.Fastening is recommended with a construction stapler.

Next, the insulation itself is laid. It must be placed in the cells of the crate. It is pre-assembled so that the distance between the bars is slightly less than the width of the insulation. Then the material will easily fit into the cell and will not need to be additionally fixed.

It is possible to lay thermal insulation without crate. At the edges of the rafters, nails are driven in, on which the wire is stretched. This method is not reliable, so it is better to install the crate.

The thermal insulator is placed in two layers: the top with an offset in relation to the bottom, so that no cracks form.

The next step is waterproofing. The film should be placed so that the insulation, crate and rafters are overlapped. Fixing is done on a construction stapler.

When the main layers are laid, you can proceed to the final finish on the outside and the flooring of the roofing material (for example, metal tiles). It is possible to independently perform the internal insulation of the roof without any difficulties, you just need to observe the nuances of the work and follow the instructions.