Radiator thermal head controls the intensity of movement of various types of coolants. The temperature regulator for a heating radiator is mounted on devices before the heating season. The operation of the device allows you to create a normal microclimate and save a fee for energy.

Why use thermostats for radiators

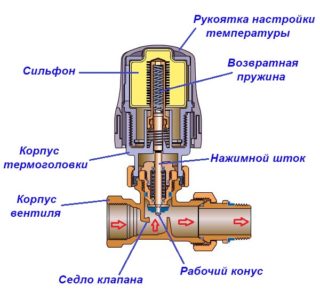

The temperature control device is mounted on batteries taking into account the thermal power of the equipment, the dimensions of the room and the climatic conditions of the region. Its design is represented by a thermal valve switching temperature modes. The special thermal head is a cylinder with a special fluid. With an increase in the temperature regime, the composition expands; with a decrease, it contracts.

Operation of the temperature controller on batteries is necessary for the following reasons:

- control of the amount of coolant in the pipeline;

- automation of heating processes;

- zonal climate and temperature control - in some rooms you can turn off the radiator, in others - leave;

- reduction in the amount of coolant used;

- disconnection from heat supply in case of breakdown of a separate apartment, and not the whole house;

- saving the boiler resource and consumables for system maintenance.

The thermostat does not increase the efficiency of the batteries and their heat transfer.

The principle of operation of the device

The principle of operation of the device is based on a change in the valve section. The thermal valve is connected to the head by a stem and a union nut. The rod moves under the influence of a load from gas or water, which expand during heating. The pressure inside the head increases, the stem gradually goes down, completely or partially closes the valve clearance.

Features of setting the thermostat for heating pipes depend on the control system:

- an automatic device with a bellows is characterized by the ability of the rod to return to its original state when changing the characteristics of the medium;

- The electronic type of controller is equipped with a thermostat. A temperature level sensor is built into it or mounted on a radiator;

- mechanical devices, the construction of which includes a valve and a crane, are produced without a bellows, have a manual mode of operation - the user must turn the valve handle.

Automatic models have a display, which displays information about the state of the coolant and work.

Types of Temperature Controllers

By the control method, you can choose a mechanical or automatic device. Depending on the filling of the siphon, thermocranes are gas and liquid. The thermostatic apparatus also varies in valve design - there are angular, straight and three-way modifications. The latter are connected to the bypass, gas supply pipe and batteries.

Features of automatic devices

The electronic thermostat for heating batteries can be programmed by changing the parameters of environmental monitoring. The device displays information about the air temperature. This characteristic is set by the user so that it remains unchanged during the heating season.

The microprocessor provides temperature control, as well as the functionality of the entire heating system.The benefits of using electronic modifications include:

- work from batteries that can be replaced;

- high energy efficiency;

- minimum power consumption;

- the presence of some battery models with the ability to charge;

- microprocessor stock control;

- extensive additional functionality.

Among the shortcomings are the need to connect devices without batteries to the network.

A thermostat is used to automatically change the parameters and transmit the temperature value. By type of work, the elements are:

- Passive. Work only in conditions of isolation from the environment.

- Active. Independently select and maintain the temperature regime of radiators.

- Phase type. They will work with changes in the physical state of the liquid.

If possible, reprogramming an automatic temperature controller can be with open or closed logic. The first can be reconfigured for any heating system. The second ones cannot be reprogrammed, but the basic parameters can be changed.

For the house or apartment, you can apply the active regulators of the Danfoss brand. They maintain the temperature of the radiator, are easy to connect. Depending on the design, you can choose a standard or external device. Danfoss thermostats have several advantages:

- simplicity of construction;

- quick installation;

- automatic adjustment and maintenance of air temperature;

- savings on the operation of individual heating.

Thermostats for central heating are only operated with auxiliary meters.

The specifics of mechanical devices

When choosing a mechanical temperature controller for apartment or home radiators, their design must be taken into account. Manufacturers produce two options.

Devices with cranes designed to adjust the volume of coolant in the battery. The crane operates in manual mode by turning all the way. The lack of devices is the deformation of the internal valve with a constant half-mode crane.

Radiator valve thermostat is:

- Needle type. It differs by manual control - the amount of coolant changes by turning the valve. The device is placed in half position without further disruption of the nodes. The disadvantage of needle models is a small cross section of the lumen inside, because of which their effectiveness is lost.

- With a mechanical temperature controller. The device is designed exclusively for the radiator. Connection is made without using power sources. Equipped with bellows for efficient operation.

Valve regulators must be installed instead of ball valves.

Thermostaticmanual the device is distinguished by autonomy of functioning in any conditions, ease of control and ease of installation. A manual thermal head is mainly suitable for a cast iron type of battery. The drawback of the regulator is a quick failure during daily switching of the rod and minimal data accuracy.

The nuances of the operation of liquid and gas-filled devices

According to the state of the thermostatic element, the devices are liquid and gas. The active substance in both cases is paraffin. Under the influence of temperature, it expands and acts on the stem with the clan connected. The pipeline with the coolant is partially blocked by the rod.

Gas-filled models are characterized by smoothness and clarity of adjustment, are equipped with a control sensor, and have a long service life. They quickly respond to temperature fluctuations. The difference between liquid models is the accuracy of pressure transfer inside the pipes to the active mechanism.

The liquid heat level controller or gas device installed on the battery differs in the type of sensors. Manufacturers produce models:

- With built-in type controller. Installation is carried out in a horizontal plane. Thus, a circular circulation is carried out, preventing fluctuations in the indicators due to the heat of the pipes.

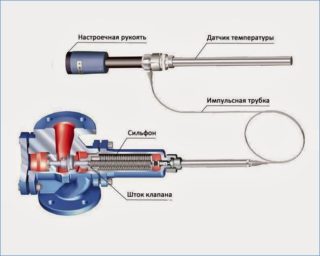

- With remote elements. Thermostatic unit is suitable for gas, electric boilers, underfloor heating systems. The device is also equipped with a water convector.

The remote sensor is suitable for a vertical thermostat and radiators located at a depth of 16 mm or more.

Installation Rules

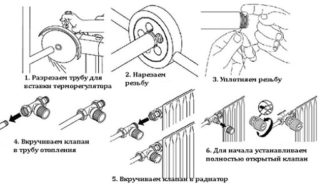

The thermal valve is installed independently in compliance with the following rules:

- Preliminary study of manufacturers instructions.

- Accurate and careful work due to fragility of parts.

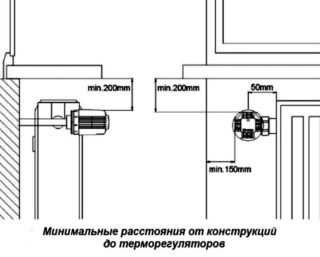

- Strict observance of horizontality of the thermostat so that it is not affected by air currents from the battery.

- Checking the direction of water movement according to the arrows on the body.

- Preliminary installation of bypasses on a single pipe system. Elements prevent failures of the entire line in case of failure of one radiator.

The installation of semi-mechanical regulators is carried out on batteries that are not covered by curtains and a decorative crate. This is necessary for the correct functioning of the device. The sensor should be 2-8 cm from the valve.

Installation sequence

The sequence of work depends on the type of device - electronic or mechanical.

Installation of electronic devices

The electronic controller is mounted on the heating battery as follows:

The electronic controller is mounted on the heating battery as follows:

- Preparation of radiators. The battery must be turned off by removing the valve and drain the remaining water. From single-pipe communications, bypass jumpers are removed. The coolant remains in the remaining radiators and continues to circulate.

- Regulator preparation. The device must be unpacked, remove the cover from the compartment for finger batteries and put them. After closing the lid, a test inclusion is performed - the display should blink.

- Mount adapter to valve base.

- Mounting the regulator using a threaded connection. The surface must be sealed with sanitary linen with impregnation or special tape. Then the device is screwed into the inlet.

- Valve marking verification. The designation of the direction of the coolant has the form of an arrow. It should correspond to the movement of water in the system at the time of work.

- Thermostat installation. Using the sensor, you can determine the temperature in the room and control the closing mechanism. The element is placed horizontally on the staples. In the case of using the remote option, it is mounted 2 or more meters from radiators.

- Calibration and adjustment of the controller according to the manufacturer's instructions.

The temperature sensor should be installed at a distance of 80 cm from the floor covering so that when it comes in contact with cold air the system will not be disturbed. The element should be protected from solar radiation, heating of household appliances.

Installation of a mechanical regulator

To install a mechanical type regulator, you will need:

- Cut off the old radiator with a horizontal battery, remove the remaining pipes and valves.

- Open the taps and let the air out of the radiator. When the coolant current is restored, the battery will heat up.

- Screw nuts and shanks of new appliances to the radiator plugs.

- Connect heating structures to connect the radiator.

- Install the radiator and strapping to the riser.

- Close doors and windows tightly so that there are no errors during adjustment.

- Unscrew the valve as far as it will go, check the air temperature using a thermometer.

- After temperature has set, turn the thermocrane in the opposite direction and set it to the minimum value.

- Check the thermometer, wait for the desired value.

- Gradually open the regulator until the water moves through the pipes.

With proper installation, the life of the thermal regulator will be from 20 to 30 years.

Features of instrument settings

A calibrated temperature controller located on the radiator of the heating system will show the correct values. The configuration is as follows:

- Correction for the operation of the device at a specific time of the day. The time is set using the arrows and the OK button.

- Date setting. The day, year and month are selected.

- Confirmation of changes. A check mark flashes on the display of electronic devices - press the OK button.

- Menu setting. The capital letter M will light up on the display. It must be held for 3 seconds until the menu opens. Then you need to press the center button, go to the settings and change them.

If you do not adjust the device, it will work according to predefined programs.

Calibration of the temperature regulator is carried out at the end of the heating of all heating systems in the room.

Temperature Controller Manufacturers

The following brands are popular among users:

- Danfoss, which produces bellows-type thermal heads for direct fixation to a proprietary valve or installation via an adapter.

- Oventrop, which produces models of regulators with the ability to set the temperature in the range from +7 to +28 degrees.

- Thermo mating valves with union nuts.

Devices of all manufacturers recommend installing a balancing tap on the return and a standard supply tap on the principle.

Using the regulator for the heating system, you can adjust the temperature in the room, normalize the microclimate, save on paying for heating in the season. Devices are suitable for installation in cottages without permanent residence, apartments or private houses.