Parapet gas boiler is an integral part of private houses and apartments, converted to autonomous heating. This is a unit that works regardless of the availability of electricity and a central chimney. The product has a closed combustion chamber, from which smoke is discharged through the pipe through the wall to the street. Thanks to this, the parapet boiler can be installed even in small rooms, without risking poisoning by gas combustion products.

History of the parapet gas boiler

The product was created in the early nineties of the last century, when mass private construction began and people refused central heating. The universal furnaces used then could work on any fuel, but an open type burner was installed in them. Since domestic enterprises were massively closed, and foreign products were not available, it was decided to develop and put into production a boiler of our own production that meets all the requirements for power and safety.

Work was carried out at the Thermo Ukraine and Luch Russia plants. In 1996, the first dual-circuit samples with compactness, 10 kW, 0.92 efficiency and a closed combustion chamber went on sale. These boilers have become the prototype units that are manufactured today.

Boiler device

The heating device is small in size, which makes it possible to install it in the kitchen, in the bathroom or in the basement. The presence of convection openings in the housing allows the unit to be used as a furnace, which makes it possible to refuse to lay strapping and batteries in the room.

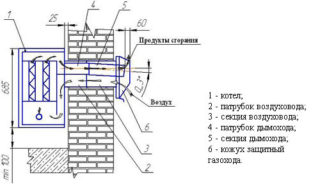

The device arrangement is quite simple:

- durable case covered with heat-resistant enamel;

- closed combustion chamber;

- gas-burner;

- wick;

- heat exchangers (coils made of copper or brass);

- chimney with wind protection.

The product includes automatic control and control devices. These include a thermocouple, an air draft sensor, and a thermometer.

Main differences and characteristics

Various models are made in floor and wall, left-side and right-hand execution. Depending on the purpose, they are equipped with one circuit - only for heating or two - to additionally heat water for domestic purposes. By the level of control, the devices are automatic and manual. Automation requires electricity. If it disappears, the boiler shuts down. Products with manual control are practically independent of environmental conditions and can even work on a gas cylinder. Turning the burner on and off is done with a thermocouple and a constant burning wick.

Advantages and disadvantages

The main advantages of parapet boilers:

- high performance;

- closed combustion chamber providing complete safety;

- compactness;

- functionality;

- universality;

- ease of use and maintenance.

Among the minuses include the need to drill holes in the wall under the pipe, which negatively affects the supporting structures. If putting a gas boiler in a private house is not a problem, then it is almost impossible to equip a city apartment with it, because of the current moratorium on such events. We should not forget about the high cost of equipment and work on its installation.

Criteria for choosing a parapet gas boiler

Since a gas boiler is purchased for decades, its choice should be taken as responsibly as possible.

When buying, you should pay attention to such criteria:

- Heat exchanger steel thickness. It should not be less than 3 mm, preferably from non-ferrous metal or stainless steel.

- Product design and its effectiveness. To save money, it is better to take dual-circuit devices with an efficiency of 0.92 or higher.

- Sizes and dimensions. If the room allows, it is advisable to dwell on the floor version. This type of boiler is more reliable and unpretentious.

- Location of connectors for connection. Depending on the installation location, a type of product with side or rear connection is selected.

- Power. The unit should be purchased at the rate of 1 kW per 10 m² of the total area of the house with a margin of 15% for extremely cold periods.

- Chimney material. The pipe should be made of thick stainless steel, resistant to high temperatures and the formation of soot inside the channel.

- Ease of installation. The cost, duration and complexity of the installation of the heating system depends on this.

- Functionality. A single-circuit boiler is smaller and cheaper, but does not solve the problem of hot water supply.

You can get information about which parapet boiler is best to choose for a home, in a specialized store that sells certified products.

The principle of operation of the parapet gas boiler

The principle of operation of an autonomous boiler is quite simple:

- The wick ignites the burner, which heats the heat exchanger.

- Water by natural current or under the influence of a pump moves along the circuit.

- After heating the working fluid to the set temperature, the thermocouple closes the gas valve and combustion stops.

- When the coolant cools to a predetermined value, the valve opens, and a constantly working wick ignites the gas.

A coaxial chimney is connected to the boiler. It is a two-pipe construction. Smoke is removed through the inside, and fresh air is supplied into the combustion chamber through the outside.

DIY boiler installation

The boiler must be installed by gas specialists. The owner of the property can prepare a foundation or place for him on the wall, drill a hole for the chimney, and make piping for heating and hot water. Fixing the device and connecting communications is performed by the master. Exceptions are cases when the boiler is connected to a gas cylinder.

So that the wind does not blow the boiler, it is necessary to make a protective cap at the installation stage at the end of the chimney, which will extinguish turbulence and strong air currents. Periodically, the inner pipe needs to be cleaned of soot, as internal deposits reduce traction.